Hemp Decorticator: Difference between revisions

No edit summary |

|||

| (15 intermediate revisions by 2 users not shown) | |||

| Line 1: | Line 1: | ||

A hemp decorticator is a machine that separates hemp stalks in to different materials that are used for a vast array of products; | =Overview= | ||

A hemp decorticator is a machine that separates hemp stalks in to different materials that are used for a vast array of products; | |||

· Bast fiber; for plastics including 3D printer filament, composite materials, textile, etc. | · Bast fiber; for plastics including 3D printer filament, composite materials, textile, etc. | ||

| Line 7: | Line 9: | ||

· Green microfiber; beauty products, CBD, nutritional products, etc. | · Green microfiber; beauty products, CBD, nutritional products, etc. | ||

[[File:Hemp_fiber,_hurd,_micro.jpg|400px|right]] | Hemp seeds can also be used and turned in to food products, ink, paint, lubricant, etc. | ||

For more examples of uses for hemp, see [[Hemp]]. | |||

{| class="wikitable" | |||

|- | |||

! Hemp stalk materials !! Stalk cross section !! Plant anatomy and uses !! Image of a hemp decorticator !! Image of a hemp decorticator | |||

|- | |||

| [[File:Hemp_fiber,_hurd,_micro.jpg|400px|right]] || [[File:Hemp stalk anatomy.png|200px|right|Cross section of a hemp stalk outlining its anatomy.]] || [[File:Hemp plant anatomy uses.jpg|200px|right]] || [[File:Hemp-decprticator-1.jpg|200px|right]] || [[File:Hemp_decorticator_2.jpg|200px|right|]] | |||

|} | |||

A hemp decorticator can also be used for other plants such as jute or kenaf. | |||

=Versions= | |||

[[Hemp decorticator V.20.01]] | |||

= Replications = | |||

No versions of this product have been replicated yet. | |||

The following format can be used to reference a replication: | |||

[Start date YYYY-MM-DD, Location, Product version, Link to a page showing some documentation of the replication process or results] | |||

=Details= | |||

Working principle: | |||

Several hemp stalks are simultaneously fed into one end of the machine, in between a pair of crop rollers/crimpers. | |||

(A Feeding hopper can facilitate feeding and create a safe distance between the user and the rollers.) | |||

When crushed in between the rollers, hemp stalks are divided into two materials: | |||

* Hurd | |||

* Bast fibers | |||

The soft bast fibers covering the woody interior come loose when the woody interior is crushed into hurd. | |||

The | The blades of the rollers are blunt so that the fibers are not damaged. | ||

First pair of rollers roll the stalks into the second pair of rollers. | |||

The rollers | The second pair of rollers spin at a different rpm than the first pair and further crushes stalk into hurd while separating fiber. | ||

Hurd and fibers are spat out from in between the second pair of rollers. | |||

With the decorticator in the image, fibers are "caught" on a Horizontal pole placed close to the second roller pair. | |||

The rollers are connected via a gears and driven by a motor. The rollers are supported by bearings positioned at each end of the shafts. | |||

[[File:Hemp decorticator.jpg|800px]] | |||

= See also = | |||

[[Decorticator]] | [[Decorticator]] | ||

[[Hemp]] | [[Hemp]] | ||

= External links = | |||

Latest revision as of 22:10, 15 May 2021

Overview

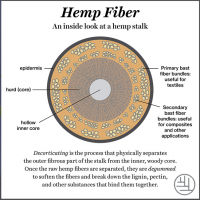

A hemp decorticator is a machine that separates hemp stalks in to different materials that are used for a vast array of products;

· Bast fiber; for plastics including 3D printer filament, composite materials, textile, etc.

· Hurd (also called shives); for paper, hempcrete, insulation, fibre board, etc.

· Green microfiber; beauty products, CBD, nutritional products, etc.

Hemp seeds can also be used and turned in to food products, ink, paint, lubricant, etc.

For more examples of uses for hemp, see Hemp.

| Hemp stalk materials | Stalk cross section | Plant anatomy and uses | Image of a hemp decorticator | Image of a hemp decorticator |

|---|---|---|---|---|

A hemp decorticator can also be used for other plants such as jute or kenaf.

Versions

Replications

No versions of this product have been replicated yet.

The following format can be used to reference a replication:

[Start date YYYY-MM-DD, Location, Product version, Link to a page showing some documentation of the replication process or results]

Details

Working principle:

Several hemp stalks are simultaneously fed into one end of the machine, in between a pair of crop rollers/crimpers.

(A Feeding hopper can facilitate feeding and create a safe distance between the user and the rollers.)

When crushed in between the rollers, hemp stalks are divided into two materials:

- Hurd

- Bast fibers

The soft bast fibers covering the woody interior come loose when the woody interior is crushed into hurd.

The blades of the rollers are blunt so that the fibers are not damaged.

First pair of rollers roll the stalks into the second pair of rollers.

The second pair of rollers spin at a different rpm than the first pair and further crushes stalk into hurd while separating fiber.

Hurd and fibers are spat out from in between the second pair of rollers.

With the decorticator in the image, fibers are "caught" on a Horizontal pole placed close to the second roller pair.

The rollers are connected via a gears and driven by a motor. The rollers are supported by bearings positioned at each end of the shafts.