Hydrogen Gas Generator: Difference between revisions

Jump to navigation

Jump to search

(→Links) |

|||

| (20 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

=Example of Off-the-Shelf Generator= | |||

*99.9% purity, 500ml/min, 4 atmosphere. [https://www.vevor.com/products/hydrogen-gas-generator-machine-0-500-ml-min-99-9-h2-high-purity-180w-lab-0-4mpa?gclid=Cj0KCQiAqdP9BRDVARIsAGSZ8AkgDq10--h7d5oOzhRVjn8PVhWxfVGtNpwUW36iRqxzPhRrW0LfsD0aAmwbEALw_wcB]. | *99.9% purity, 500ml/min, 4 atmosphere. [https://www.vevor.com/products/hydrogen-gas-generator-machine-0-500-ml-min-99-9-h2-high-purity-180w-lab-0-4mpa?gclid=Cj0KCQiAqdP9BRDVARIsAGSZ8AkgDq10--h7d5oOzhRVjn8PVhWxfVGtNpwUW36iRqxzPhRrW0LfsD0aAmwbEALw_wcB]. | ||

*At 4 atmospheres, can fill a 1000 gallon propane tank - in 4 days. At 1 atmosphere - one day! | *At 4 atmospheres, can fill a 1000 gallon propane tank - in 4 days. At 1 atmosphere - one day! | ||

* | *$3500 of generators (same as above but at $700/unit) gets us 1.5 kWhr of usable storage with a generator. That is the same cost as a 20kW new battery bank - which can last 10 years in off-grid apps. We are a factor of 13x higher capital cost than batteries at this stage - which can be solved only by reducing cost of hydrogen generation equipment. | ||

*Ideal conditions - 40kWhr to generate 1 kg of hydrogen - [https://www.nrel.gov/docs/fy09osti/44103.pdf] | |||

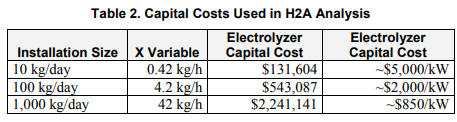

*Look at basic capital cost from last link: | |||

[[File:capitalhydrogen.png]] - note - check is 65kW is the required electrolyzer. Quick calc - 1.5 kg/hr optimial production, but given loss, .75kg/hr, or indeed about 15 hours for 10kg of hydrogen. | |||

*'''For sensemaking - $1-5k capital costs per kW electrolyzer. A 1 kW electrolyzer - for reference, the 500 ml/hr generator in link above requires 180W.''' If we take the electrolyzer above at $1k for 500 ml/hr - we need about 5 of those for 1kW of electrolyzer - or about $5k. But it takes about 24x as much electrolyzer to generate 10kG/day (or 10 gallons per day). Each 1000 gallon propane tank can store about 1.2kg of hydrogen, at 4 atmospheres. Capital cost there is $5k x4 or $20k for the electrolyzer. That's where open source comes in - to attain mass production via production by the masses. The complexity cost coupled with parasitic loss can be displaced by distributed production. | |||

*Thus, the imperative is generation equipment - lowering its cost. | |||

*Take a look at the payback time of the electrolyzer - $20/day with gasoline at $2/gal equivalent. Capital cost is $130k. Capital payback is 6500 days, or 18 years. With capital costs 1/5 of that, we have payback in 3 years. Thus, the goal is to reduce the capital cost 5x. With $2.2M capital - | |||

*Note that the 1000 kg/day already achieved that - $2000/day payback revenue. So the payback time is only 3 years using existing technology! | |||

*So next, learn about [[Engine Conversion to Hydrogen]] | |||

=Links= | =Links= | ||

*[[Solar Hydrogen Production]] | *[[Solar Hydrogen Production]] | ||

*[[Hydrogen Compression]] | *[[Hydrogen Compression]] | ||

Latest revision as of 20:03, 18 November 2020

Example of Off-the-Shelf Generator

- 99.9% purity, 500ml/min, 4 atmosphere. [1].

- At 4 atmospheres, can fill a 1000 gallon propane tank - in 4 days. At 1 atmosphere - one day!

- $3500 of generators (same as above but at $700/unit) gets us 1.5 kWhr of usable storage with a generator. That is the same cost as a 20kW new battery bank - which can last 10 years in off-grid apps. We are a factor of 13x higher capital cost than batteries at this stage - which can be solved only by reducing cost of hydrogen generation equipment.

- Ideal conditions - 40kWhr to generate 1 kg of hydrogen - [2]

- Look at basic capital cost from last link:

- note - check is 65kW is the required electrolyzer. Quick calc - 1.5 kg/hr optimial production, but given loss, .75kg/hr, or indeed about 15 hours for 10kg of hydrogen.

- note - check is 65kW is the required electrolyzer. Quick calc - 1.5 kg/hr optimial production, but given loss, .75kg/hr, or indeed about 15 hours for 10kg of hydrogen.

- For sensemaking - $1-5k capital costs per kW electrolyzer. A 1 kW electrolyzer - for reference, the 500 ml/hr generator in link above requires 180W. If we take the electrolyzer above at $1k for 500 ml/hr - we need about 5 of those for 1kW of electrolyzer - or about $5k. But it takes about 24x as much electrolyzer to generate 10kG/day (or 10 gallons per day). Each 1000 gallon propane tank can store about 1.2kg of hydrogen, at 4 atmospheres. Capital cost there is $5k x4 or $20k for the electrolyzer. That's where open source comes in - to attain mass production via production by the masses. The complexity cost coupled with parasitic loss can be displaced by distributed production.

- Thus, the imperative is generation equipment - lowering its cost.

- Take a look at the payback time of the electrolyzer - $20/day with gasoline at $2/gal equivalent. Capital cost is $130k. Capital payback is 6500 days, or 18 years. With capital costs 1/5 of that, we have payback in 3 years. Thus, the goal is to reduce the capital cost 5x. With $2.2M capital -

- Note that the 1000 kg/day already achieved that - $2000/day payback revenue. So the payback time is only 3 years using existing technology!

- So next, learn about Engine Conversion to Hydrogen