November 2008 Funding: Difference between revisions

No edit summary |

m (Text replace - "openfarmtech.org/weblog" to "blog.opensourceecology.org") |

||

| (One intermediate revision by one other user not shown) | |||

| Line 11: | Line 11: | ||

[[Image:Retarded_program.jpg]] | [[Image:Retarded_program.jpg]] | ||

We got good funding and delivered good results (see [http:// | We got good funding and delivered good results (see [http://blog.opensourceecology.org/?p=391]) | ||

Since we essentially had one additional person here, we built only one Hexayurt, and used existing kitchen facilities. We did install an on-demand water heater for our shower. | Since we essentially had one additional person here, we built only one Hexayurt, and used existing kitchen facilities. We did install an on-demand water heater for our shower. | ||

| Line 26: | Line 26: | ||

=November Funding Allocation Plans= | =November Funding Allocation Plans= | ||

We are carrying over $500 from the October cycle (see report - [http:// | We are carrying over $500 from the October cycle (see report - [http://blog.opensourceecology.org/?p=391]) | ||

We still need roofing materials, drainage tube, doors, windows, cement, 4x8 lumber for framing and roof beams, steel for stove/sauna combination. These materials total about $2000. | We still need roofing materials, drainage tube, doors, windows, cement, 4x8 lumber for framing and roof beams, steel for stove/sauna combination. These materials total about $2000. | ||

| Line 33: | Line 33: | ||

Note that success in building the sawmill depends on finding a volunteer to do the development work. We have a person coming here in November, so the sawmill is likely to be a success. The payoff in terms of a high quality, low cost, high production sawmill are great. We expect to produce kits for the above for about $600, without counting track costs. | Note that success in building the sawmill depends on finding a volunteer to do the development work. We have a person coming here in November, so the sawmill is likely to be a success. The payoff in terms of a high quality, low cost, high production sawmill are great. We expect to produce kits for the above for about $600, without counting track costs. | ||

[[Category: | [[Category:Past Events]] | ||

[[Category:Funding]] | |||

Latest revision as of 17:26, 2 July 2013

Discussion of Plans from October

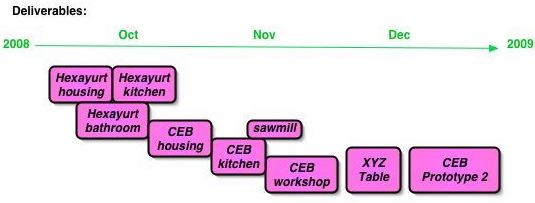

Here is the program we proposed at the beginning of October:

Augmented program with your support:

Program with little or no support:

We got good funding and delivered good results (see [1]) Since we essentially had one additional person here, we built only one Hexayurt, and used existing kitchen facilities. We did install an on-demand water heater for our shower.

Thus, November begins with CEB workshop construction - and the sawmill prototype. These are essential parts of the Global Village Construction set - [2]

November Budget

We are now in November - and the augmented program (above) is still valid. We are continuing with our facility construction, and require about $2000 in materials for completion. We are also proposing $1400 for materials for a LifeTrac powered, 25 hp chainsaw mill prototype. This is relevant to the replication of the CEB CSM business model - where self-generated lumber allows low-cost construction of facilities. This falls under the scenario of decentralization technology-based Global Villages.

Review of the sawmill by Ben Hansen, sustainable forester from Viroqua, WI, informs us that production rates of 2400 linear feet of lumber are realistic with such a sawmill.

Thus, the total goal for November is $3400.

November Funding Allocation Plans

We are carrying over $500 from the October cycle (see report - [3]) We still need roofing materials, drainage tube, doors, windows, cement, 4x8 lumber for framing and roof beams, steel for stove/sauna combination. These materials total about $2000.

We are allocating $1400 for the drive sprocket ($300), drive sprocket mounting ($200), 4' chainsaw bar ($200), and steel track ($700) for the sawmill prototype. The track will be made of 2x4x1/4" steel or comparable structure. Hydraulics are not included on the sawmill in this cycle.

Note that success in building the sawmill depends on finding a volunteer to do the development work. We have a person coming here in November, so the sawmill is likely to be a success. The payoff in terms of a high quality, low cost, high production sawmill are great. We expect to produce kits for the above for about $600, without counting track costs.