Biomass to Fuel: Difference between revisions

(Added some more categories to the page) |

|||

| (One intermediate revision by one other user not shown) | |||

| Line 63: | Line 63: | ||

*FT uses 200 or 300C temperature processes and 30 bar - [http://www.zero.no/transport/bio/fischer-tropsch-reactor-fed-by-syngas] | *FT uses 200 or 300C temperature processes and 30 bar - [http://www.zero.no/transport/bio/fischer-tropsch-reactor-fed-by-syngas] | ||

*Max FT yield of c5+ liquid fuel - 65% - [www.ecn.nl/docs/library/report/2004/rx04041.pdf] | *Max FT yield of c5+ liquid fuel - 65% - [www.ecn.nl/docs/library/report/2004/rx04041.pdf] | ||

[[Category: | |||

[[Category:Research]] [[Category: Biofuel]] [[Category: Bio-Petrochemistry]] | |||

Latest revision as of 02:25, 22 October 2020

Introduction

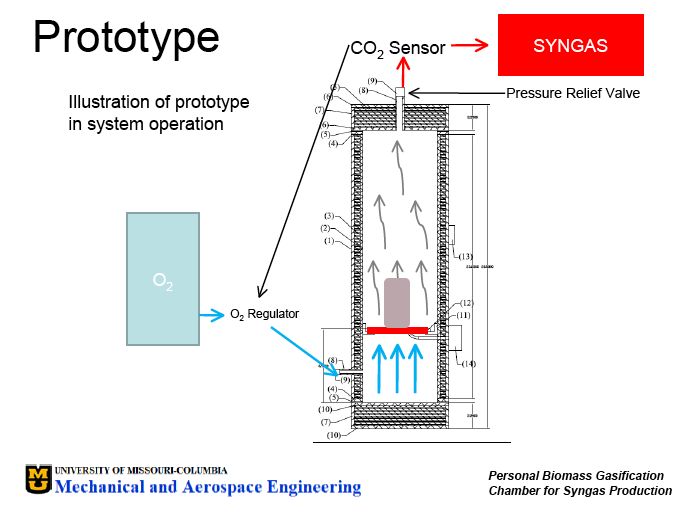

Based on a personal gasifier (care of Dr. Yuyi Lin [1], Mike Koch, et al.):

which generates gas from any cellulosic biomass:

we can take the process further to make liquid fuels.

Extension to Liquid Fuel Production

Utilizing Fischer-Tropsch synthesis, a process proven on a large scale:

(from Wikipedia)

our collaboratory will evaluate the possibilities for optimization for small-scale fuel generation. We mean personal fuel makers - a radical proposition. We are writing a grant proposal for this - and will consider a dual license - free to small producers, and royalty-based for companies with gross sales of a million or more dollars.

Student Projects

Engineering, materials science, and design students are welcome to engage in research on this topic. The questions to be answered are:

- Optimization of gasifier for controlled feed gas production

- Integration of gasifier with proven Fischer-Tropsch technology

- Optimization of efficiency for the above for the small scale (100-1000 gallon per day production

History of Research

This site is worth researching for an overview of research on Fischer-Tropsch synthesis to date.

Pyrolysis Oil, Methane Storage

http://en.wikipedia.org/wiki/Pyrolysis_oil

http://www.bioenergywiki.net/index.php/Pyrolysis_oil

http://en.wikipedia.org/wiki/Methane_clathrate

Business Planning Due Diligence

- Average corn and soybean yields - 140 and 30 bushels per acre - [2]

- 11 lbs of oil per 60 lb bushel of soybeans - [3]

- Iowa soybean yields - 40 bushels/acre - [4]

- Average soybean oil yields per acre - 48 gallons - [5]

- Corn alcohol yield per acre - 230 gallongs - [8]

- Soybeans require an average of 12.5 gallons of fuel per acre to grow and harvest them - [9]

- $50/acre switchgrass cost - [10]

- Average switchgrass yield - 4-6 dry tons (central v. southeast) - [11]

- Average wood yield - 3 dry tons - [12]

- Biomass cost = $30/dry ton and $60 for switchgrass and wood - [13]

- 40% charcoal yield from dry wood - [14]

- Experiments show 40-50% charcoal yield - [15]

- 40% charcoal - [16]

- 20-30% charcoal yield in Missouri kiln - [folk.ntnu.no/lekangso/kurs2005/presentations/Day4-6_Bio-Energy/background/Gronli.pdf]

- Charcoal contains 30-60% of energy content of original biomass - [folk.ntnu.no/lekangso/kurs2005/presentations/Day4-6_Bio-Energy/background/Gronli.pdf]

- Max theoretical yield of Fischer Tropsch is 75% - [17]

- FT uses 200 or 300C temperature processes and 30 bar - [18]

- Max FT yield of c5+ liquid fuel - 65% - [www.ecn.nl/docs/library/report/2004/rx04041.pdf]