Compressed Air Energy Storage Calculations: Difference between revisions

Jump to navigation

Jump to search

(→About) |

(→About) |

||

| (One intermediate revision by the same user not shown) | |||

| Line 4: | Line 4: | ||

**This could be true if compressor efficiency is 60% and tool efficiency is 20-30% for standard air tools. | **This could be true if compressor efficiency is 60% and tool efficiency is 20-30% for standard air tools. | ||

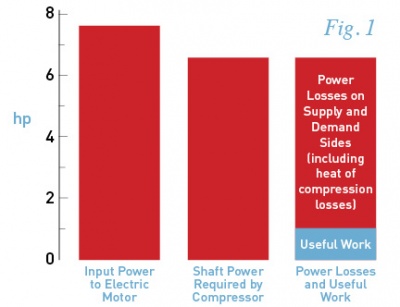

*7-8 hp input to compressor yields 1 hp at the air tool shaft. [https://fluidpowerjournal.com/air-tool-is-inefficient/] | *7-8 hp input to compressor yields 1 hp at the air tool shaft. [https://fluidpowerjournal.com/air-tool-is-inefficient/] | ||

[[File:compressedair.jpg|400px]] | |||

Losses: | |||

[[File:compressedairlosses.jpg|400px]] | |||

=Calculations= | =Calculations= | ||

Latest revision as of 20:01, 19 May 2025

Compressed air energy storage or gravity water storage costs 10x less than any other based on 100 year vs 10 year lifetime of the system.

About

- 'Only 10% to 20% of the energy required to generate compressed air ever reaches the point of use' - [1]

- This could be true if compressor efficiency is 60% and tool efficiency is 20-30% for standard air tools.

- 7-8 hp input to compressor yields 1 hp at the air tool shaft. [2]

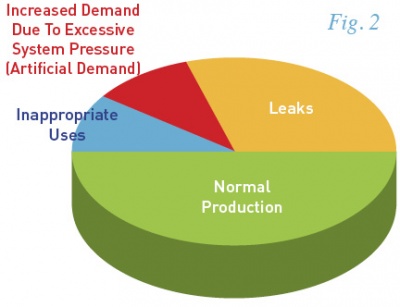

Losses:

Calculations

- Work to compress, thus energy stored in isothermal conditions - is W = P1V1 * ln(P2/P1) [3]

- Adiabatic compression - [W = P1V1 - P2V2 / (1 - γ)] [4]

- Let's take industrial gas cylinders with K, T, 3K, 6K standards - 300 cu ft for T [5]. 2200-2600 psi is the standard, but also 3000 PSI and 6000 PSI.

- T type - 300 cf

Other

- 150 PSI, 660 gal receiver tank - $3500 [6]

Links

Full treatment at Compressed Air Calculations

Full treatment at Compressed Air Calculations