The Spark Build: Difference between revisions

Jump to navigation

Jump to search

| Line 2: | Line 2: | ||

Main | Main | ||

*List people and allocate tasks | *List people and allocate tasks | ||

#James | |||

#Jason | |||

#Tom | |||

#James' Daughter | |||

#Katie | |||

#Audrey | |||

#Gary | |||

#Rob | |||

#Nat | |||

#Rob | |||

#Scholar 1 | |||

#Scholar 2 | |||

#Leandra | |||

#Lucas | |||

#Jordan | |||

#Cory | |||

#Ian | |||

#Siku | |||

#DJ | |||

*Shop setup | *Shop setup | ||

*Parts run | *Parts run | ||

| Line 10: | Line 30: | ||

Tasks: | Tasks: | ||

*Take off wheels | *Take off wheels | ||

*Create cut lists | |||

* | |||

*Cutting materials | *Cutting materials | ||

*Take off tracks | *Take off tracks | ||

| Line 21: | Line 43: | ||

*Workshop inventory | *Workshop inventory | ||

*Tool prep | *Tool prep | ||

*Create cannibalization log | |||

*Work instructions | |||

*Graphical work instructions | |||

=Quality Control= | =Quality Control= | ||

Revision as of 15:41, 12 July 2013

Task Allocation

Main

- List people and allocate tasks

- James

- Jason

- Tom

- James' Daughter

- Katie

- Audrey

- Gary

- Rob

- Nat

- Rob

- Scholar 1

- Scholar 2

- Leandra

- Lucas

- Jordan

- Cory

- Ian

- Siku

- DJ

- Shop setup

- Parts run

Shopping List

- Lock washers

- Bandsaw blade

- Cutoff wheels- 14"

Tasks:

- Take off wheels

- Create cut lists

- Cutting materials

- Take off tracks

- Remove power cube

- Get blocks and stand tractor on blocks

- Shop signs

- Eyewash

- Generate cut list

- Generate procedures

- Build Power Cube

- Workshop inventory

- Tool prep

- Create cannibalization log

- Work instructions

- Graphical work instructions

Quality Control

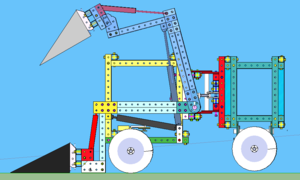

- Download File:Cab and Loader Arms 12pm Jul 11.skp

- Loader forearm stability

- Force on arm lift cylinder mounting

- 9 degree cylinder angle means 9400 lbs lift force

- Foot pedal detail

- Valve 1 mounting plate detail

- Valve 2 mounting plate detail

- Foot pedal detail

- Pin tight with lever

- Seat mounting

- Wheel shaft procedure

- Loader down pressure

- Bolts clearing everywhere

- Bolting feasibility everywhere

- Build order correct for each moduleo

- Bottom cylinder mounting spacer means can't bolt the tubes together as is. Solution: bore out holes or move mounting 4" forward and wheel 4" forward and use a x8" plate for mounting

- 1/2" stickout on wheel me

- Narrower cab by 8" on each side to 32 inch door and 40" wide cab, to save 13' of tubing ($170)

Parts

First Choice

- 3 Spool, 25 gpm Motor Valve for Wheels, auxiliary implements, and turning - [1]. Needs Power Beyond Sleeve - [2]

- 25 GPM Joystick valve - [3]

- [4] hoses - [4]

- [2] hoses - [5]