Justin Log 2013: Difference between revisions

No edit summary |

|||

| Line 33: | Line 33: | ||

2V/4.88mv resolution gives 0-409 range or .244V resolution from the plasma torch or theoretically 3 mill this should be fine. | 2V/4.88mv resolution gives 0-409 range or .244V resolution from the plasma torch or theoretically 3 mill this should be fine. | ||

3.Event monitoring- needed to monitor crash/limit switches and also torch control variables, if the torch slows down as in a curve the voltage will rise and cause a erroneous lower of the torch. These conditions need to be addressed in software. | ''Use with grbl'' The G-code/stepper driver code running on the Atmega utilizes the fixed timer1 interrupt (TIMER1_COMPA_vect) to pulse I think there will be latency issues. | ||

I recommend a separate processor for height control. | |||

===Use with oxy torch=== | |||

Most height control systems for oxy torches use a capacitive sensor with a ring: | |||

http://www.hypertherm.com/en/Products/Automated_cutting/Torch_height_controls/sensor_ohc.jsp | |||

http://www.agelkom.com.tr/prod02.htm | |||

there is not the same issue of noise so I think it would be feasible to make a capacitive sensor based height controller that could be used in both cases. With the plasma torch the capacitive sensor is used ONLY for touch off then it switches to the voltage sensing for the cutting. The oxy-fuel would use the capacitive sensing throughout the cut at a high sample rate. | |||

3.'''Event monitoring'''- needed to monitor crash/limit switches and also torch control variables, if the torch slows down as in a curve the voltage will rise and cause a erroneous lower of the torch. These conditions need to be addressed in software. | |||

| Line 43: | Line 58: | ||

Possible systems | Possible systems | ||

http://www.candcnc.com/LCTHC.html | |||

=Sat Jun 22, 2013= | =Sat Jun 22, 2013= | ||

Revision as of 01:56, 18 July 2013

Wed jul 17 2013

Cnc torch table notes

Height control

Specs for stable plasma cut

Three components to plasma height control:

1. IHS (initial height sensing)- this is the touch off height or pierce height for the torch (pierce at 150-200% of the cut height). Capacitive sensors would work best for thin material since a mechanical switch could deflect the material giving a false reading. Two chips I have used for touch screen buttons are:

freescale: http://www.freescale.com/files/sensors/doc/data_sheet/MPR121.pdf

and

Qprox: http://media.digikey.com/pdf/Data%20Sheets/Quantum%20PDFs/Qt160_07.pdf

These provide baseline sampling compensation so they act like a switch more than a sensor but for the initial height sensing I think they would work well.

2. Cutting height- is determined by the plasma torches cutting voltage, since the plasma torch uses constant current a 1% change in voltage (100 to 101 volts) is equal to several thousands (typically .015 or more) of arc gap change. This voltage can be read directly from the plasma torch, most torches have a voltage output (example):

PowerPlasma 60S OCV 200V working voltage 88-100 has outputs for 1/16 or 1/50 which gives a output of about 4V

This can be measured by a a/d on a microcontrol but needs to be isolated first. The sample rate should allow a A/D reading every .5 second.

The Atmega1280/328 sample rate for a A/D is 14 clock cycles the A/D has a internal clock that should be set to the lowest sample rate of 50KHZ this will help with noise and give a more accurate reading. It seems like a half second latency is the cutoff for sensing and correcting at 25KHZ 14 clocks would give 1785 samples, to deal with noise probably 50 samples should be averaged. 10 bit resolution gives a 1023/AVcc if a 5v system is used that gives 4.88mV resolution.

1023/5AVcc = 4.88mV resolution

100v/50 = 2V output from plasma torch

2V/4.88mv resolution gives 0-409 range or .244V resolution from the plasma torch or theoretically 3 mill this should be fine.

Use with grbl The G-code/stepper driver code running on the Atmega utilizes the fixed timer1 interrupt (TIMER1_COMPA_vect) to pulse I think there will be latency issues.

I recommend a separate processor for height control.

Use with oxy torch

Most height control systems for oxy torches use a capacitive sensor with a ring:

http://www.hypertherm.com/en/Products/Automated_cutting/Torch_height_controls/sensor_ohc.jsp

http://www.agelkom.com.tr/prod02.htm

there is not the same issue of noise so I think it would be feasible to make a capacitive sensor based height controller that could be used in both cases. With the plasma torch the capacitive sensor is used ONLY for touch off then it switches to the voltage sensing for the cutting. The oxy-fuel would use the capacitive sensing throughout the cut at a high sample rate.

3.Event monitoring- needed to monitor crash/limit switches and also torch control variables, if the torch slows down as in a curve the voltage will rise and cause a erroneous lower of the torch. These conditions need to be addressed in software.

Links

http://www.everlastgenerators.com/downloads/PowerPlasma%202013.pdf

http://www.candcnc.com/PDF/LCTHC-Manual_REV8.pdf

Possible systems

http://www.candcnc.com/LCTHC.html

Sat Jun 22, 2013

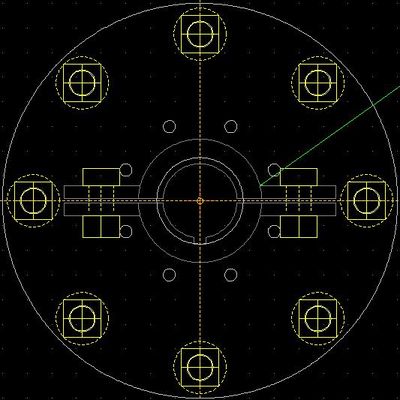

Did 3 Inch Wheel Hub for tractor wheels, sprockets.

Mon May 20, 2013

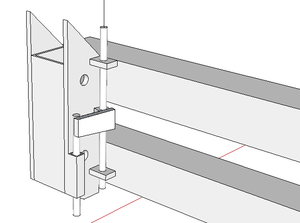

Discussing Bobcat Standard Quick Attach for LifeTrac with Marcin. Trying to log in to wiki with OpenID.

Sat May 18, 2013

Spent a good day designing Bobcat Standard Quick Attach for LifeTrac during OSE Design Sprint.