OSE CircularKnitic v18.03: Difference between revisions

Jump to navigation

Jump to search

| Line 1: | Line 1: | ||

=Overview= | =Overview= | ||

* OSE's Fork of [[CircularKnitic Parametric|CircularKnitic]] | * OSE's Fork of [[CircularKnitic Parametric|CircularKnitic]], the open source circulate knitting machine | ||

* Code available on GitHub https://github.com/OpenSourceEcology/circular_knitic | * Code available on GitHub https://github.com/OpenSourceEcology/circular_knitic | ||

Revision as of 02:47, 29 May 2018

Overview

- OSE's Fork of CircularKnitic, the open source circulate knitting machine

- Code available on GitHub https://github.com/OpenSourceEcology/circular_knitic

Goals

Needle Accomidation

- Long tails

- Bent back tails

- Test 3D printed needles

Fabric Spool

- Apply constant tension on fabric

- Roll onto spool for easy handling and storage

Part Code

CKvars.scad

- Variables to be defined for all aspects of the specific machine to be built

- These variables should be set the same for each part that is rendered

- need to define nominal distance between top of needle to top of CKp4.

- need to increase number of p3 and p4 parts.

- calculate printer footprint for each part.

////MAIN SETTINGS////

//select needle size file that will be used

include <CKneedleVars-KH260.scad>;

//number of "p2" parts around circle

p2number=36;

//number of needles mounted on each "p2" part

p2needles=10;

//number of "p3" parts around circle

p3number=18;

//number of "p4" parts around circle

p4number=18;

//distance from the inside face of one needle to the next

needle2needle=8.414; //default=14.35615

//calculated diameter from inside edge of needles

p2needlegrooveID=((needle2needle*p2number*p2needles)/PI);

////MATERIALS////

upper_surfaceH=5; //thickness of upper rotating plate

bottom_surface_motor_gearsH=6; //thickness of geared rotating plate

////PART SETTINGS////

//plate

pPspace1=12; //? space from main table top to first plate

pPplate1=6; //thickness of geared plated

pPspace2=12; //space between geared plate and mountain plate

pPplate2=5;

//"connector0912" connects upper_surface plate to bottom_surface geared plate

connector0912H=12;

connector0912L=25;

connector0912W=8;

connector0912HoleOD=3; //hole diameter

connector0912HoleC2C=17; //center of hole to center of other hole

//BearringSmall1312_x_4.stl

bearingholderSmallB2C=5.5; //from base of bearing holder to center of bearing

bearingholderSmallBOD=10; //Outside Diameter of bearing

bearingholderSmallBID=5; //Inside Diameter of bore hole of bearing

bearingholderSmallBW=4; //Width of bearing

//BearringZ

bearingholderZBOD=10; //Outside Diameter of bearing

bearingholderZBID=5; //Inside Diameter of bore hole of bearing

bearingholderZBW=4; //Width of bearing

bearingholderZB2C=(bearingholderZBOD/2)+upper_surfaceH+connector0912H+bottom_surface_motor_gearsH+bearingholderSmallB2C+(bearingholderSmallBOD/2); //from base of bearing holder to center of bearing

//p2

needleWidthslop=0.4; //exta thickness

needleWidth=nX+needleWidthslop;

p2needlegroovefromID=2.0;

p2ID=p2needlegrooveID-(p2needlegroovefromID*2);

p2needlegrooveDepthslop=0.4; //exta thickness

p2needlegrooveDepth=nY+p2needlegrooveDepthslop;

//p2H calculated below;

p2W=p2needlegroovefromID+p2needlegrooveDepth;

p2OD=p2ID+(p2W*2);

//p2holeH calculated below

p2holeD=2;

p2holeCSD=4.01726;

p2holeCSL=1.5;

p2clear=0.5; //distance above top of p4 from flipper in down position

//p3

p3wiggle=0.1;

p3baseH=3;

p3wallW=(nH-nY)/2; //half of needle butt

p3baseholeD=3;

p3baseholeScrewHeadD=5.68;

p3baseholefromODID=p3baseholeScrewHeadD/2;

p3baseholenumber=4;

p3ridgeW1=3;

p3ridgeW2=5;

p3ridgeH=5;

p3wallholefromtop=5;

p3wallchamfW=2;

p3wallchamfH=3;

//p3wallH in calculations below

//p3grooveH1 in calculations below

//p3grooveH2 in calculations below

p3grooveWslop=0.8; //extra Width in needle groove

p3grooveW=nX+p3grooveWslop;

p3clear=5; //distance from top of p3 to needle flipper in down position

p3baseID=p2ID-(p3wiggle*2)-(p3ridgeW2*2)-(p3baseholeScrewHeadD*2);

p3baseOD=p2OD+(p3wiggle*2)+(p3wallW*2)+(p3wallchamfW*2)+(p3baseholeScrewHeadD*2);

//p4

p4rampW=4;

p4rampH=14.57;

p4rampfromID=2.5;

p4rampoverhangH=4;

p4rampfromOD=1.34;

p4rampC1=10;

p4rampC2=40;

p4rampC2transX=10;

p4rampC2transZ=3.82;

p4baseH=11;

p4basegapH=8;

p4baseW=11.2;

p4basegapW=5.09;

p4clawW=9;

p4holesnumber=3;

p4holeH=5;

//mountain

pMwallT=7.5; //min thickness from groove to back wall

pMgroove=nH-nY-p3wallW+1; //depth of groove

pMgrooveAngle=45;

pMgrooveC1=pPspace2; //top of groove at position 1 "entrance"

pMgrooveC2=nC+2; //top of groove at position 2 "push down"

pMgrooveC3=44.25; //top of groove at position 3 "top center"

pMgrooveSlop=2;

pMwallHextra=5.75; //extra height above groove at heighest point

//calculated settings

centerlineD=p2ID+(p2W+(p3wiggle*2));

p3grooveH1=bottom_surface_motor_gearsH+bearingholderSmallB2C+(bearingholderSmallBOD/2)+(pMgrooveSlop/2);

p3grooveH2=p3grooveH1+pMgrooveC3+(pMgrooveSlop/2);

p4baseOD=centerlineD+p4baseW;

p4baseID=centerlineD-p4baseW;

p4basegapOD=centerlineD+p4basegapW;

p4basegapID=centerlineD-p4basegapW;

firstcenter=(((((360/p2number/p2needles/2)/360*(p2OD*PI))-(needleWidth/2))/((360/p2number/p2needles/2)/360*(p2OD*PI)))*(360/p2number/p2needles/2))/2;

p2H=bottom_surface_motor_gearsH+bearingholderSmallB2C+(bearingholderSmallBOD/2)+pMgrooveC3+nA-nB-nC-nF-p3baseH-(p4rampH+p4baseH-p4basegapH)-p2clear;;

p3wallH=bottom_surface_motor_gearsH+bearingholderSmallB2C+(bearingholderSmallBOD/2)+pMgrooveC2+nA-nB-nC-nF-p3clear;

p2holeH=p3grooveH2+((p3wallH-p3grooveH2)/2);

////SETTINGS OUTPUT ECHOS///

echo("Total Needles:", p2number*p2needles);

echo("Millimeters Between Needles:", PI*p2needlegrooveID/(p2number*p2needles));

echo("OD of p3:", p3baseOD);

Needles

CKneedleVars-KH260.scad

- purchased here: http://shop.sckmcl.com.hk/product_info.php?products_id=136

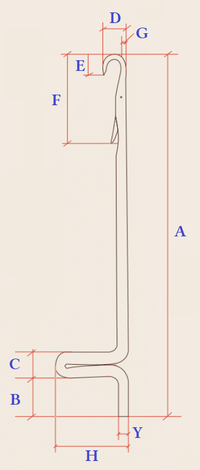

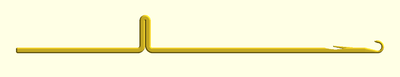

//NEEDLE for Brother KH260 //measurements by dorkmo nX=1.4; //typical thickness from side to side nY=2.44; //typical thickness from front to back nA=157.9; //total length of needle nB=53; //distance from bottom of needle to bottom of bent tab. nC=4.82; //thickness of bent tab. top to bottom. nD=5.48; //hook front to back nE=4.10; //from top of loop to bottom of hook nF=22.0; //from top of loop to bottom of flipper in down position nG=1.10; //minimum thickness of hook. front to back. nH=17.03; //max distance from front to back nT=0; //0=straight tail 1=bent tail aka folded back. Y of tail = C if T=1.

CKneedleVars-SK120.scad

- difficult to find these exact needles for sale

//NEEDLE for SK120 //measured by original CircularKnitic team nX=1.4; //typical thickness from side to side nY=2.44; //typical thickness from front to back nA=97.73; //total length of needle nB=7.72; //distance from bottom of needle to bottom of bent tab. nC=4.92; //thickness of bent tab. top to bottom. nD=5.09; //hook front to back nE=4.62; //from top top loop to bottom of hook nF=19.94; //top to bottom of flipper in down position nG=1.04; //minimum thickness of hook. front to back. nH=16.4; //max distance from front to back nT=0; //0=straight tail 1=bent tail aka folded back. Y of tail = C of T=1.

3D Prints

- Parts to be printed on the 3D printer

CKp2.scad

include <CKvars.scad>;

CKp2();

module CKp2(){

rez=360/p2number*2*2;

$fn=rez; //defines resolution of circles.

translate([p2OD/2,0,0]){

difference(){

cylinder(h=p2H,d=p2OD);

cylinder(h=p2H,d=p2ID);

translate([-p2OD/2,-p2OD/2,0]){

cube([p2OD,p2OD/2,p2H]);

}

rotate([0,0,-360/p2number]){

translate([-p2OD/2,0,0])

cube([p2OD,p2OD/2,p2H]);

}

for(i=[1:p2needles]){

rotate([0,0,(360/p2number/p2needles/2)-(360/p2number/p2needles*i)]){

translate([-p2OD/2-0.2,-needleWidth/2,0])

cube([p2needlegrooveDepth+0.2,needleWidth,p2H]);

}

}

rotate([0,0,-360/p2number/p2needles]){

translate([-p2OD/2-0.2,0,p2holeH])

rotate([0,90,0]){

union(){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD);

translate([0,0,((p2OD-p2ID)/2)-p2holeCSL]){

cylinder(h=p2holeCSL+2, d=p2holeCSD);

}

} //end union

}

}

rotate([0,0,-360/p2number/p2needles*(p2needles-1)]){

translate([-p2OD/2-0.2,0,p2holeH])

rotate([0,90,0]){

union(){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD);

translate([0,0,((p2OD-p2ID)/2)-p2holeCSL]){

cylinder(h=p2holeCSL+2, d=p2holeCSD);

}

} //end union

}

}

echo(((((360/p2number/p2needles/2)/360*(p2OD*PI))-(needleWidth/2))/((360/p2number/p2needles/2)/360*(p2OD*PI)))*(360/p2number/p2needles/2));

firstcenter=(((((360/p2number/p2needles/2)/360*(p2OD*PI))-(needleWidth/2))/((360/p2number/p2needles/2)/360*(p2OD*PI)))*(360/p2number/p2needles/2))/2;

rotate([0,0,-firstcenter]){

translate([-p2OD/2-0.2,0,p2holeH])

rotate([0,90,0]){

union(){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD);

translate([0,0,((p2OD-p2ID)/2)-p2holeCSL]){

cylinder(h=p2holeCSL+2, d=p2holeCSD);

}

} //end union

}

}

rotate([0,0,-360/p2number+firstcenter]){

translate([-p2OD/2-0.2,0,p2holeH])

rotate([0,90,0]){

union(){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD);

translate([0,0,((p2OD-p2ID)/2)-p2holeCSL]){

cylinder(h=p2holeCSL+2, d=p2holeCSD);

}

} //end union

}

}

}

}

} //end module

CKp3.scad

- Added holes in base for long tails

- does this need to be bigger to allow for some slop?

- what to do if needle has bent back tail?

include <CKvars.scad>;

CKp3();

module CKp3(){

rez=p2number*p2needles*2;

//p2number*p2needles*2

//p2number*2*2;

$fn=rez; //defines resolution of circles.

centerlineD=p2ID+(p2W+(p3wiggle*2));

echo(centerlineD);

translate([p3baseOD/2,0,0]){

difference(){

union(){

cylinder(h=p3baseH,d=p3baseOD);

difference(){

cylinder(h=p3ridgeH+p3baseH,d=centerlineD-((p2W+(p3wiggle*2)/2)));

translate([0,0,p3baseH])

cylinder(h=p3ridgeH,d1=centerlineD-(p3ridgeW2*2)-((p2W+(p3wiggle*2)/2)),d2=centerlineD-(p3ridgeW1*2)-((p2W+(p3wiggle*2)/2)));

}

difference(){

translate([0,0,p3baseH])

cylinder(h=p3wallchamfH,d1=centerlineD+((p3wallchamfW+p3wallW)*2)+((p2W+(p3wiggle*2)/2)),d2=centerlineD+(p3wallW*2)+((p2W+(p3wiggle*2)/2)));

cylinder(h=p3wallchamfH+p3baseH,d=centerlineD+((p2W+(p3wiggle*2)/2)));

}

difference(){

cylinder(h=p3wallH,d=centerlineD+(p3wallW*2)+((p2W+(p3wiggle*2)/2)));

cylinder(h=p3wallH,d=centerlineD+((p2W+(p3wiggle*2)/2)));

}

} //end main union

cylinder(h=p3wallH,d=p3baseID);

translate([-p3baseOD/2,-p3baseOD/2,0]){

cube([p3baseOD,p3baseOD/2,p3wallH]);

}

rotate([0,0,-360/p3number]){

translate([-p3baseOD/2,0,0])

cube([p3baseOD,p3baseOD/2,p3wallH]);

}

//slots

for(i=[1:p2needles*(p2number/p3number)]){

rotate([0,0,(360/p2number/p2needles/2)-(360/p2number/p2needles*i)]){

translate([((-centerlineD-(p3wallW*2)-((p2W+(p3wiggle*2)/2)))/2)-0.1,-p3grooveW/2,p3grooveH1])

cube([p3wallW+0.2,p3grooveW,p3grooveH2-p3grooveH1]);

}

}

//base needle holes

for(i=[1:p2needles*(p2number/p3number)]){

rotate([0,0,(360/p2number/p2needles/2)-(360/p2number/p2needles*i)]){

translate([-p2OD/2,-needleWidth/2,-0.01])

cube([p2needlegrooveDepth,needleWidth,p3wallH+0.02]);

}

}

//base mounting holes

for(i=[1:p3baseholenumber]){

rotate([0,0,(((360/p3number/p3baseholenumber))/2)-((360/p3number/p3baseholenumber)*i)]){

translate([-(p3baseID/2)-p3baseholefromODID,0,0])

cylinder(h=p3baseH,d=p3baseholeD,$fn=18);

}

}

for(i=[1:p3baseholenumber]){

rotate([0,0,(((360/p3number/p3baseholenumber))/2)-((360/p3number/p3baseholenumber)*i)]){

translate([-(p3baseOD/2)+p3baseholefromODID,0,0])

cylinder(h=p3baseH,d=p3baseholeD,$fn=18);

}

}

//first and last holes

rotate([0,0,-firstcenter]){

translate([((-centerlineD-(p3wallW*2)-((p2W+(p3wiggle*2)/2)))/2)-0.1,0,p2holeH+p3baseH])

rotate([0,90,0]){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD, $fn=18);

}

}

rotate([0,0,-(360/(p3number))+firstcenter]){

translate([((-centerlineD-(p3wallW*2)-((p2W+(p3wiggle*2)/2)))/2)-0.1,0,p2holeH+p3baseH])

rotate([0,90,0]){

#cylinder(h=p2OD-p2ID+0.2, d=p2holeD, $fn=18);

}

}

//middle holes

for(i=[0:(p2number/p3number)-1]){

rotate([0,0,(-360/p2number/p2needles)+(i*-360/p2number)]){

translate([((-centerlineD-(p3wallW*2)-((p2W+(p3wiggle*2)/2)))/2)-0.1,0,p2holeH+p3baseH])

rotate([0,90,0]){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD,$fn=18);

}

}

} //end for

for(i=[0:(p2number/p3number)-1]){

rotate([0,0,(-360/p2number/p2needles*(p2needles-1))+(i*-360/p2number)]){

translate([((-centerlineD-(p3wallW*2)-((p2W+(p3wiggle*2)/2)))/2)-0.1,0,p2holeH+p3baseH])

rotate([0,90,0]){

cylinder(h=p2OD-p2ID+0.2, d=p2holeD, $fn=18);

}

}

}//end for

//end middle holes

}

}

} //end module

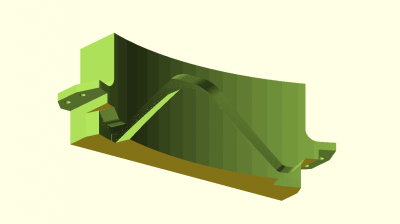

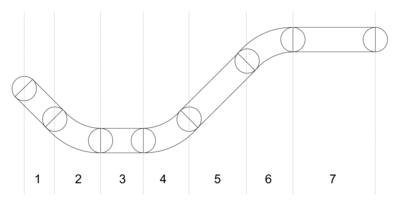

CKpM.scad "mountain"

- need to test with different size needle and spaces between plates

- takes a long time to render, have to be patient

- need to up the resolution of circles at large diameter machine

- need to set a minimum thickness of the mountain.

- mounting brackets not rendering correctly on large diameter machine

include <CKvars.scad>;

CKpM(); //mountain

CKpMgrooveturnR=15; //radius of upper curved path in groove

CKpMgrooveturnR2=8; //radius of lower curved path in groove

CKpMgrooveD=nC+pMgrooveSlop; //diamter of groove cut

CKpMID=p2OD+2; //inside diameter of main wall

CKpMgrooveOD=pMgroove+(CKpMID/2); //center to OD of groove

CKpMp7X=5; //half of length of plateu of groove. preferably whole number

CKpMp3X=2.5; //length of flat area of section 3

CKpMcutRez=2; //cuts per degree

CKpMcutDeg=(((CKpMp7X/2)*360/(PI*CKpMID))/CKpMp7X); //degrees per unit diameter

CKpMcutcylRez=36; //number of sides on groove cutting clylinder

CKpMcutA=45; //angle of cut path

//calc'd

mi=(CKpMID*PI)/360; //degrees in mm at CKpMID

echo("mi=");

echo(mi);

CKpMd7=round((CKpMp7X)*360/(PI*CKpMID)*10)/10; //degrees around ID

echo(CKpMd7);

CKpMd6=round((cos(CKpMcutA)*CKpMgrooveturnR)*360/(PI*CKpMID)*10)/10;

echo(CKpMd6);

CKpMp6Y=0;

CKpMd5=round((tan(CKpMcutA)*(((pMgrooveC3-(CKpMgrooveD/2)+(CKpMgrooveturnR*cos(asin((((CKpMd7+CKpMd6)-CKpMd7)*(PI*CKpMID)/360)/CKpMgrooveturnR))-CKpMgrooveturnR))-((CKpMgrooveD/2)+((sin(CKpMcutA)*CKpMgrooveturnR2)*360/(PI*CKpMID))))))*360/(PI*CKpMID)*10)/10;

// not good code CKpMd5=round((cos(CKpMcutA)*(pMgrooveC3+pMwallHextra+(CKpMgrooveD/2)))*360/(PI*CKpMID)*10)/10;

//height of center of circle at top of 5 //pMgrooveC3-(CKpMgrooveD/2)+(CKpMgrooveturnR*cos(asin((((CKpMd7+CKpMd6)-CKpMd7)*(PI*CKpMID)/360)/CKpMgrooveturnR))-CKpMgrooveturnR)

//height of center of circle at bottom of 5

//CKpMgrooveD+((sin(CKpMcutA)*CKpMgrooveturnR2)*360/(PI*CKpMID))

//total height of 5 //((pMgrooveC3-(CKpMgrooveD/2)+(CKpMgrooveturnR*cos(asin((((CKpMd7+CKpMd6)-CKpMd7)*(PI*CKpMID)/360)/CKpMgrooveturnR))-CKpMgrooveturnR))-(CKpMgrooveD+((sin(CKpMcutA)*CKpMgrooveturnR2)*360/(PI*CKpMID))))

echo(CKpMd5);

//center to center degrees in section 4

CKpMd4=round((cos(CKpMcutA)*CKpMgrooveturnR2)*360/(PI*CKpMID)*10)/10;

//old bad code CKpMd4=(cos(CKpMcutA)*((pMgrooveC3-(CKpMgrooveD/2)+(CKpMgrooveturnR*cos(asin(((((CKpMd7+(CKpMd6))-(0.1))-CKpMd7)*(PI*CKpMID)/360)/CKpMgrooveturnR))-CKpMgrooveturnR))-((cos(CKpMcutA)*CKpMgrooveturnR))));

echo(CKpMd4);

CKpMd3=round((CKpMp3X)*360/(PI*CKpMID)*10)/10; //degrees around ID

echo(CKpMd3);

CKpMd2=round((cos(CKpMcutA)*CKpMgrooveturnR2)*360/(PI*CKpMID)*10)/10;

echo(CKpMd2);

//height of center of circle at top of 2

//CKpMgrooveD+((sin(CKpMcutA)*CKpMgrooveturnR2)*360/(PI*CKpMID))

//need to fix below

CKpMd1=round(((cos(CKpMcutA)*((pMgrooveC1-(((((CKpMgrooveD/2)-(CKpMgrooveturnR2*cos(asin((((CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3+CKpMd2)-(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3))*(PI*CKpMID)/360)/CKpMgrooveturnR2))-CKpMgrooveturnR2)))))-(sin(CKpMcutA)*(CKpMgrooveD/2)))*(1/sin(CKpMcutA)))))*360/(PI*CKpMID)*10)/10;

echo("degrees 1:");

echo(CKpMd1);

CKpMd0=(cos(CKpMcutA)*(CKpMgrooveD/2))*360/(PI*CKpMID);

pMH=pMgrooveC3+pMwallHextra;

pMbwOD=((p2OD+2)/2)+pMwallT+pMgroove;

echo(pMbwOD);

module CKpM(){

//test cube

// translate([-71.4,120,0])

// cube([pMgrooveC1,pMgrooveC1,pMgrooveC1]);

union(){

difference(){

translate([-(p2OD+2),0,0])

cube([(p2OD+2)*2,((p2OD+2)/2)+pMwallT+pMgroove,pMH]);

cylinder($fn=180,d=CKpMID, h=pMH);

//cut main end

//need to calc exactly so height of path entrance matches bottom of top plate

rotate([0,0,(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3+CKpMd2+CKpMd1-CKpMd0)])

mirror([1,0,0])

cube([CKpMID*4,CKpMID*4,pMH]);

mirror([1,0,0])

rotate([0,0,(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3+CKpMd2+CKpMd1-CKpMd0)])

mirror([1,0,0])

cube([CKpMID*4,CKpMID*4,pMH]);

//left needle path cut

needlepathLEFT();

//right needle path cut

mirror([1,0,0])

needlepathLEFT();

} //end main difference

pMsidetab();

mirror([1,0,0])

pMsidetab();

} //end main union

} //end main module

module pMsidetab(){

translate([0,0,pPspace2+pPplate2])

difference(){

rotate([0,0,-(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3+CKpMd2+CKpMd1-CKpMd0)])

difference(){

union(){

cube([12.5,(pMbwOD*2),4]);

translate([0,0,4])

difference(){

cube([4,(pMbwOD*2),4]);

translate([4,0,0])

rotate([0,-45,0])

cube([8,(pMbwOD*2),8]);

}

}

translate([4+(8.5/2),(CKpMID/2)+13.5,0])

cylinder($fn=36,d=3,h=5);

translate([4+(8.5/2),(pMbwOD*(1/cos(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3+CKpMd2+CKpMd1-CKpMd0)))-5.5,0])

cylinder($fn=36,d=3,h=5);

}

translate([0,-50,0])

cube([(CKpMID/2),((CKpMID/2)+3.5)*cos(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3+CKpMd2+CKpMd1-CKpMd0)+50,(CKpMID/2)]);

translate([0,pMbwOD,0])

cube([(pMbwOD*2),(pMbwOD*2),(pMbwOD*2)]);

}

} //end sidetab module

module needlepathLEFT(){

//////////////////////

// needle path //

//////////////////////

//7

for(i=[(0.1):(0.2):CKpMd7-(0.1)]){

hull(){

//odd

translate([0,0,pMgrooveC3-(CKpMgrooveD/2)])

rotate([270,0,i-(0.1)])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

//even

translate([0,0,pMgrooveC3-(CKpMgrooveD/2)])

rotate([270,0,i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

}//end hull 1

hull(){

//even

translate([0,0,pMgrooveC3-(CKpMgrooveD/2)])

rotate([270,0,i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

//odd

translate([0,0,pMgrooveC3-(CKpMgrooveD/2)])

rotate([270,0,i+(0.1)])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

}//end hull 2

}//end fors

//6

for(i=[(CKpMd7)+(0.1):(0.2):(CKpMd7+(CKpMd6))-(0.1)]){

hull(){

//odd

translate([0,0,pMgrooveC3-(CKpMgrooveD/2)+(CKpMgrooveturnR*cos(asin(((i-CKpMd7-(0.1))*(PI*CKpMID)/360)/CKpMgrooveturnR))-CKpMgrooveturnR)])

rotate([270,0,i-(0.1)])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

//even

translate([0,0,pMgrooveC3-(CKpMgrooveD/2)+(CKpMgrooveturnR*cos(asin(((i-CKpMd7)*(PI*CKpMID)/360)/CKpMgrooveturnR))-CKpMgrooveturnR)])

rotate([270,0,i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

}//end hull 1

hull(){

//even

translate([0,0,pMgrooveC3-(CKpMgrooveD/2)+(CKpMgrooveturnR*cos(asin(((i-CKpMd7)*(PI*CKpMID)/360)/CKpMgrooveturnR))-CKpMgrooveturnR)])

rotate([270,0,i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

//odd

translate([0,0,pMgrooveC3-(CKpMgrooveD/2)+(CKpMgrooveturnR*cos(asin(((i-CKpMd7+(0.1))*(PI*CKpMID)/360)/CKpMgrooveturnR))-CKpMgrooveturnR)])

rotate([270,0,i+(0.1)])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

}//end hull 2

}//end fors

//5

for(i=[(CKpMd7+CKpMd6)+(0.1):(0.2):(CKpMd7+CKpMd6+CKpMd5+CKpMd4)-(0.1)]){

hull(){

//odd

translate([0,0,pMgrooveC3-(CKpMgrooveD/2)+(CKpMgrooveturnR*cos(asin(((((CKpMd7+(CKpMd6))-(0.0))-CKpMd7)*(PI*CKpMID)/360)/CKpMgrooveturnR))-CKpMgrooveturnR)-((tan(CKpMcutA)*(i-0.1-(CKpMd7+CKpMd6))*mi))])

rotate([270,0,i-(0.1)])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

//even

translate([0,0,pMgrooveC3-(CKpMgrooveD/2)+(CKpMgrooveturnR*cos(asin(((((CKpMd7+(CKpMd6))-(0.0))-CKpMd7)*(PI*CKpMID)/360)/CKpMgrooveturnR))-CKpMgrooveturnR)-((tan(CKpMcutA)*(i-(CKpMd7+CKpMd6-0.0))*mi))])

rotate([270,0,i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

} //end hull 1

hull(){

//even

translate([0,0,pMgrooveC3-(CKpMgrooveD/2)+(CKpMgrooveturnR*cos(asin(((((CKpMd7+(CKpMd6))-(0.0))-CKpMd7)*(PI*CKpMID)/360)/CKpMgrooveturnR))-CKpMgrooveturnR)-((tan(CKpMcutA)*(i-(CKpMd7+CKpMd6-0.0))*mi))])

rotate([270,0,i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

//odd

translate([0,0,pMgrooveC3-(CKpMgrooveD/2)+(CKpMgrooveturnR*cos(asin(((((CKpMd7+(CKpMd6))-(0.0))-CKpMd7)*(PI*CKpMID)/360)/CKpMgrooveturnR))-CKpMgrooveturnR)-((tan(CKpMcutA)*(i+0.1-(CKpMd7+CKpMd6))*mi))])

rotate([270,0,i+(0.1)])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

} //end hull 2

} //end for

//4

for(i=[(CKpMd7+CKpMd6+CKpMd5)-(0.1):(0.2):(CKpMd7+CKpMd6+CKpMd5+CKpMd4)+(0.1)]){

translate([0,0,(CKpMgrooveD/2)-(CKpMgrooveturnR2*cos(asin(((i-(CKpMd7+CKpMd6+CKpMd5)-(0.0))*(PI*CKpMID)/360)/CKpMgrooveturnR2))-CKpMgrooveturnR2)])

rotate([270,0,((CKpMd7+CKpMd6+CKpMd5+CKpMd4)+(CKpMd7+CKpMd6+CKpMd5))-i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

}

///3

for(i=[((CKpMd7+CKpMd6+CKpMd5+CKpMd4)+(0.1)):(0.2):((CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3)-(0.1))]){

hull(){

//even

translate([0,0,(CKpMgrooveD/2)])

rotate([270,0,i-(0.1)])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

//even

translate([0,0,(CKpMgrooveD/2)])

rotate([270,0,i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

}//end hull 1

hull(){

//even

translate([0,0,(CKpMgrooveD/2)])

rotate([270,0,i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

//odd

translate([0,0,(CKpMgrooveD/2)])

rotate([270,0,i+(0.1)])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

}//end hull 2

}//end fors

//2

for(i=[(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3)+(0.1):(0.2):(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3+CKpMd2)-(0.1)]){

hull(){

//even

translate([0,0,(CKpMgrooveD/2)-(CKpMgrooveturnR2*cos(asin(((i-(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3)-(0.1))*(PI*CKpMID)/360)/CKpMgrooveturnR2))-CKpMgrooveturnR2)])

rotate([270,0,i-(0.1)])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

//even

translate([0,0,(CKpMgrooveD/2)-(CKpMgrooveturnR2*cos(asin(((i-(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3))*(PI*CKpMID)/360)/CKpMgrooveturnR2))-CKpMgrooveturnR2)])

rotate([270,0,i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

}//end hull 1

hull(){

//even

translate([0,0,(CKpMgrooveD/2)-(CKpMgrooveturnR2*cos(asin(((i-(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3))*(PI*CKpMID)/360)/CKpMgrooveturnR2))-CKpMgrooveturnR2)])

rotate([270,0,i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

//odd

translate([0,0,(CKpMgrooveD/2)-(CKpMgrooveturnR2*cos(asin(((i-(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3)+(0.1))*(PI*CKpMID)/360)/CKpMgrooveturnR2))-CKpMgrooveturnR2)])

rotate([270,0,i+(0.1)])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

}//end hull 2

}//end fors

difference(){

for(i=[(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3)+(0.1):(0.2):(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3+CKpMd2)-(0.1)]){

translate([0,0,0])

rotate([270,0,i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

}

cylinder($fn=180,d=CKpMID, h=pMH);

}

//1

hull(){

difference(){

for(i=[(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3+CKpMd2)+(0.1):(0.2):(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3+CKpMd2+CKpMd1+1)-(0.1)]){

translate([0,0,((CKpMgrooveD/2)+((sin(CKpMcutA)*CKpMgrooveturnR2)*360/(PI*CKpMID)))+((tan(CKpMcutA)*(i-(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3+CKpMd2-0.0))*mi))])

rotate([270,0,i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

}

cylinder($fn=180,d=CKpMID, h=pMH);

} //end diff

difference(){

for(i=[(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3+CKpMd2)+(0.1):(0.2):(CKpMd7+CKpMd6+CKpMd5+CKpMd4+CKpMd3+CKpMd2+CKpMd1)-(0.1)]){

translate([0,0,0])

rotate([270,0,i])

cylinder($fn=CKpMcutcylRez,d=CKpMgrooveD,h=CKpMgrooveOD);

}

cylinder($fn=180,d=CKpMID, h=pMH);

} //end difference

} //end hull

///////////////////////////

} //end needlepathLEFT module

2D Cuts

- Parts to be cut out using a CNC machine

CKc2.scad

- rotating plate with gears

- need to calculate teeth per distance around outer diameter

include <CKvars.scad>;

// Copyright 2010 D1plo1d

// LGPL 2.1

t2t=6.858;

c2width=50;

c2gap=2;

c2OD=(c2width*2)+(c2gap*2)+p2OD+(p3wiggle*2)+(p3wallW*2);

c2ID=(c2gap*2)+p2OD+(p3wiggle*2)+(p3wallW*2);

c2teeth=((c2OD*PI)/t2t)-1;

c2dipitch=c2teeth/(c2OD*PI);

gear(c2teeth,circular_pitch=false,diametral_pitch=c2dipitch,pressure_angle=87, clearance=0.01);

//test_involute_curve();

//test_gears();

//demo_3d_gears();

// Geometry Sources:

// http://www.cartertools.com/involute.html

// gears.py (inkscape extension: /usr/share/inkscape/extensions/gears.py)

// Usage:

// Diametral pitch: Number of teeth per unit length.

// Circular pitch: Length of the arc from one tooth to the next

// Clearance: Radial distance between top of tooth on one gear to bottom of gap on another.

module gear(number_of_teeth,

circular_pitch=false, diametral_pitch=false,

pressure_angle=20, clearance = 0)

{

if (circular_pitch==false && diametral_pitch==false) echo("MCAD ERROR: gear module needs either a diametral_pitch or circular_pitch");

//Convert diametrial pitch to our native circular pitch

circular_pitch = (circular_pitch!=false?circular_pitch:180/diametral_pitch);

// Pitch diameter: Diameter of pitch circle.

pitch_diameter = number_of_teeth * circular_pitch / 180;

pitch_radius = pitch_diameter/2;

// Base Circle

base_diameter = pitch_diameter*cos(pressure_angle);

base_radius = base_diameter/2;

// Diametrial pitch: Number of teeth per unit length.

pitch_diametrial = number_of_teeth / pitch_diameter;

// Addendum: Radial distance from pitch circle to outside circle.

addendum = 1/pitch_diametrial;

//Outer Circle

outer_radius = pitch_radius+addendum;

outer_diameter = outer_radius*2;

// Dedendum: Radial distance from pitch circle to root diameter

dedendum = addendum + clearance;

// Root diameter: Diameter of bottom of tooth spaces.

root_radius = pitch_radius-dedendum;

root_diameter = root_radius * 2;

half_thick_angle = 360 / (4 * number_of_teeth);

difference()

{

union()

{

rotate(half_thick_angle) circle($fn=number_of_teeth*2, r=root_radius*1.001);

for (i= [1:number_of_teeth])

//for (i = [0])

{

rotate([0,0,i*360/number_of_teeth])

{

involute_gear_tooth(

pitch_radius = pitch_radius,

root_radius = root_radius,

base_radius = base_radius,

outer_radius = outer_radius,

half_thick_angle = half_thick_angle);

}

}

}

projection(cut = true) //use projection to create 2D

{

cylinder(d=c2ID,h=100);

}

}

}

module involute_gear_tooth(

pitch_radius,

root_radius,

base_radius,

outer_radius,

half_thick_angle

)

{

pitch_to_base_angle = involute_intersect_angle( base_radius, pitch_radius );

outer_to_base_angle = involute_intersect_angle( base_radius, outer_radius );

base1 = 0 - pitch_to_base_angle - half_thick_angle;

pitch1 = 0 - half_thick_angle;

outer1 = outer_to_base_angle - pitch_to_base_angle - half_thick_angle;

b1 = polar_to_cartesian([ base1, base_radius ]);

p1 = polar_to_cartesian([ pitch1, pitch_radius ]);

o1 = polar_to_cartesian([ outer1, outer_radius ]);

b2 = polar_to_cartesian([ -base1, base_radius ]);

p2 = polar_to_cartesian([ -pitch1, pitch_radius ]);

o2 = polar_to_cartesian([ -outer1, outer_radius ]);

// ( root_radius > base_radius variables )

pitch_to_root_angle = pitch_to_base_angle - involute_intersect_angle(base_radius, root_radius );

root1 = pitch1 - pitch_to_root_angle;

root2 = -pitch1 + pitch_to_root_angle;

r1_t = polar_to_cartesian([ root1, root_radius ]);

r2_t = polar_to_cartesian([ -root1, root_radius ]);

// ( else )

r1_f = polar_to_cartesian([ base1, root_radius ]);

r2_f = polar_to_cartesian([ -base1, root_radius ]);

if (root_radius > base_radius)

{

//echo("true");

polygon( points = [

r1_t,p1,o1,o2,p2,r2_t

], convexity = 3);

}

else

{

polygon( points = [

r1_f, b1,p1,o1,o2,p2,b2,r2_f

], convexity = 3);

}

}

// Mathematical Functions

//===============

// Finds the angle of the involute about the base radius at the given distance (radius) from it's center.

//source: http://www.mathhelpforum.com/math-help/geometry/136011-circle-involute-solving-y-any-given-x.html

function involute_intersect_angle(base_radius, radius) = sqrt( pow(radius/base_radius,2) - 1);

// Polar coord [angle, radius] to cartesian coord [x,y]

function polar_to_cartesian(polar) = [

polar[1]*cos(polar[0]),

polar[1]*sin(polar[0])

];

// Test Cases

//===============

module test_gears()

{

gear(number_of_teeth=51,circular_pitch=200);

translate([0, 50])gear(number_of_teeth=17,circular_pitch=200);

translate([-50,0]) gear(number_of_teeth=17,diametral_pitch=1);

}

module demo_3d_gears()

{

//double helical gear

translate([50,0])

{

linear_extrude(height = 10, center = true, convexity = 10, twist = -45)

gear(number_of_teeth=17,diametral_pitch=1);

translate([0,0,10])

rotate([0,180,180/17])

linear_extrude(height = 10, center = true, convexity = 10, twist = 45)

gear(number_of_teeth=17,diametral_pitch=1);

}

//spur gear

translate([0,-50]) linear_extrude(height = 10, center = true, convexity = 10, twist = 0)

gear(number_of_teeth=17,diametral_pitch=1);

}

module test_involute_curve()

{

for (i=[0,1,2,3,4,5,6,7,8,9,10,11,12,13,14,15])

{

translate(polar_to_cartesian([involute_intersect_angle( 0.1,i) , i ])) circle($fn=15, r=0.5);

}

}

To Do

- upper plate - mountain holder

- gear plate tooth calculations

- table plate w/nema etc

- weight holder plate

- small bearing holder

- big bearing holder

- Z bearing holder

- plate connector - i think this was done already, find?

- outerConnector

- CKp4 yard holder change dimensions based on needle layout

- update mountain for larger OD's. need to up rezolution

- create 3D printed electronics box?

- yard stick holder etc

- tensioner etc

See Also

- Open Source Textile Construction Set

- Open Source Circular Knitting Machine

- CircularKnitic Parametric