CEB Press: Difference between revisions

(Moving content to 'CEB Press Intro') |

No edit summary |

||

| Line 1: | Line 1: | ||

---- | ---- | ||

'''This page is going to be turned into a redirect to [[CEB Press Intro]], but first we need to strip out the useful info and put it where it's needed''' | '''This page is going to be turned into a redirect to [[CEB Press Intro]], but first we need to strip out the useful info and put it where it's needed''' | ||

| Line 10: | Line 9: | ||

</center> | </center> | ||

</html> | </html> | ||

===Budget=== | ===Budget=== | ||

Revision as of 21:51, 25 February 2011

This page is going to be turned into a redirect to CEB Press Intro, but first we need to strip out the useful info and put it where it's needed

Budget

Bill of Materials

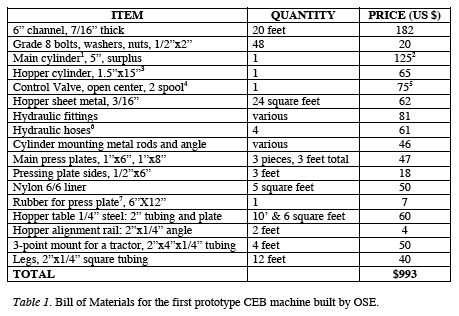

Here we present an economic analysis for the CEB machine to explain costs involved.

Here is the Bill of Materials (BOM) for the CEB prototype:

References:

- https://www.surpluscenter.com/item.asp?UID=2008010512293756&item=9-1143-08&catname=hydraulic

- Gotten from surplus.

- https://www.surpluscenter.com/item.asp?UID=2008010512293756&item=9-7156&catname=hydraulic

- https://www.surpluscenter.com/item.asp?UID=2008010512293756&item=9-6702&catname=hydraulic for $156

- Gotten from surplus.

- Item # 905-12120 and 905-1236 at https://www.surpluscenter.com/

- Item 8609K13 at http://www.mcmaster.com/

The main cylinder and control valve used were from surplus, so this price may rise by about $250 for the cylinder and $100 for the valve, for a total of about $1350 in readily-accessible parts. The total number of hours spent building this protoptype was about 140 hours. The time expected for fabricating the second prototype is 40 hours. Production runs are expected to take about 20 hours per machine, using an XYZ torch table for fabrication assist.

Fabrication Facility

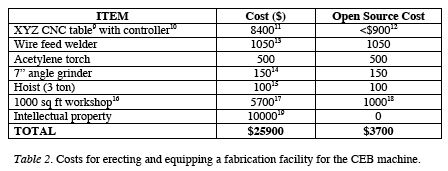

Here are the capitalization requirements for fabrication capacity. The Cost column reflects the price structure if off-the-shelf tools and materials - and proprietary development procedures - are utilized. This cost is conservative, as intellectual property costs are probably higher than the $10k that was specified. The alternative route, or the Open Source Cost, is that which utilizes open source know-how and is built on a land-based facility. The open source option means that certain equipment may be fabricated readily from available components when a design and bill of materials is available.

References: 9. www.torchmate.com ; 10. Does not include the control computer; 11. Torchmate 3, http://www.torchmate.com/overview/index2.htm ; 12. http://bluumax.com/ ; 13. http://www.harborfreight.com/cpi/ctaf/displayitem.taf?Itemnumber=43550 ; 14. http://www.northerntool.com/webapp/wcs/stores/servlet/product_6970_200306001_200306001 ; 15. http://www.northerntool.com/webapp/wcs/stores/servlet/product_6970_18544_18544 ; 16. Not including land costs; 17. Cheapest barn kit: http://diypolebarns.com/pb_kits.php , more expensive: http://www.shelter-kit.com/b_prices.html ; 18. Using CEB construction with on-site soils, plus site-milled lumber leaves only doors, windows, foundation, and electrical costs of building; 19. This is difficult to estimate, but here we will include 200 hours of development work at $50 per hour- for producing 2 prototypes and testing prior to production runs.

In particular, the great cost reducer in the open source route is the availability of: (1) a low-cost XYZ table, (2), low cost workshop building, and (3), absence of intellectual property costs. In total, the price of putting together a fabrication facility is only $3700 if one has access to land, some kind of tractor or skid loader for material handling, and utilizes onsite building materials (CEBs and milled lumber) to construct the workshop space. It should be added that more labor will go into building an XYZ table than buying one, but not much more, if a transparent bill of materials and fabrication procedure is available. Workshop building time may also increase over the off-shelf option.

The XY table is a pricey solution if obtained off-the-shelf. New kits cost $8k at the low end for an industrial duty, 4x8 foot table. We should note that, as expected from the open source development method, ridiculously low costs are feasible for the CNC table. For example, a small CNC mill is under $200. The electronics of a CNC XY table are inexpensive. Three stepper motors plus controller and power supply cost $45. (http://bluumax.com/ - Note - these stepper motors are half the required size, so we expect the real price to scale accordingly.) Rails may be the expensive part, and other than that, it’s mostly a structure that can be fabricated via xyz bolt-together design. The CNC table should be accessible at <$500 plus structural steel at approximately $400. That is a Factor 10 reduction over the competition.

The cost structure for building a physical production facility for the CEB will be documented fully with forthcoming experience in 2008. We will be building this facility at Factor E Farm. Part of the development will be deploying an open source XYZ table, which we expect to cost <$900 in parts. There may be additional costs involved in finalizing a simple design for the XYZ table. The goal is a facility that can produce 1 CEB machine every 3 days with 1 fabricator working full time.

We will set up a social enterprise website to raise between $3700-5000 for deploying CEB machine fabrication. This site will designed to motivate the minimal funding of the facility, by directing as many potential stakeholders to the site as possible. Stakeholders include owner-builders interested in natural building, building organizations such as Habitat for Humanity, disaster relief organizations, building contractors, and a wide range of others. We are asking for collaboration in directing potential stakeholders to the funding website.

In summary, this is our first experiment of co-funding a significant production facility. Deployment funds will be used to build the facility, procure some tools, and build an open source version of the XYZ table. Utilizing existing collaboration, we will use up to $3k from the budget to design, build, and deploy the XYZ table. Together with Factor e Farm contribution of facility space, a fabricator who has already been recruited, and utilization of onsite materials for facility construction – we believe that we have an attractive package that can be funded. Costs and risk are distributed, and low overhead makes the entire project dirt cheap for the significance of the promised deliverable. It is a pressing issue (no pun intended) for us to deploy CEB machine production with 3-5 day delivery time – for proving a novel, state-of-art peer production mechanism.

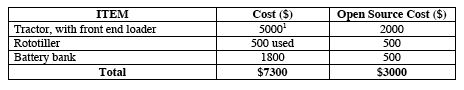

Heavy Equipment

The balance of the budget for the open source CEB development is in materials handling and testing: a tractor with front end loader and rototiller. The tractor is required for soil preparation: digging soil and rototilling the soil to prepare it for use in the CEB machine. The tractor is also used to power the CEB machine for testing, and for material handling of raw steel that is used in the CEB machine. Moreover, we are presently utilizing a tractor to generate 20 kW of electricity by using a power take-off (PTO) generator. This powers the welder and other equipment, but we aim to replace this with a renewable power system as soon as we can. We currently run smaller electrical tools with a 3 kW inverter and a battery bank. These costs summarized are:

Notes: 1. We are considering an Allis Chalmers D17 Series IV Diesel tractor as a robust, all purpose tractor with good hydraulics

Timeline

The goals are to produce a hydraulically-driven, manually operated CEB press ready for sale by October, 2008. By November, we aim to produce a fully automated hydraulic machine. By December, we aim to develop a training program for builders of the CEB machine.

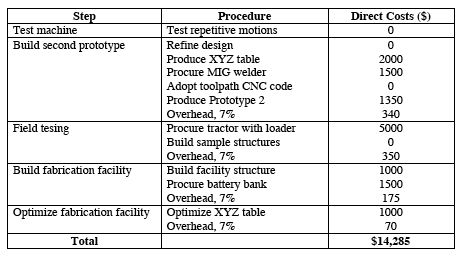

Given the budget explanations above, here are the funding cycles that we are proposing for this project. Delivery date for optimized production is November 1, 2008, when we will begin filling orders.

The funding cycle overview is:

The table above shows the deployment costs with 7% overhead for fiduciary duties of funding collection management. The cycles in detail are:

The first funding cycle starts Feb 1, and continues for 4 weeks. We hope to collect the necessary funding via a concerted 2 week effort with our volunteer fundraising team. The funding cycle carries on for 4 weeks, but the actual developments with the proceeds collected last longer.

Cycle 1: Feb. 1 – Feb. 28 Collection Cycle, $5190 - XYZ table, and 2nd Prototype

- Recruiting core team

- Recruiting reviewers

- Documenting all past design and fabrication work

- Distributing present effort out for review

- Designing XYZ table by Feb. 1

- Reviewing XYZ table by Feb. 7

- Procuring fabrication bids for table by Feb. 14

- Fabricating XYZ table, by Mar. 8

- Procuring MIG welder by Mar. 8

- Producing prototype 2 by Mar. 31

Cycle 2: March 1-March 31 Collection Cycle, $5350 - Demo Buildings

- Procure tractor with front-end loader by April 7

- We will build our first significant demonstration structures with the 2 CEB prototypes. Construction will continue for 1 month to document experience with the ergonomics and economics of this method, and to verify field performance of the 2 CEB prototypes.

Cycle 3: April 1-April 30 Collection Cycle, $2675 - Fabrication Facility

- Note: this covers the foundation, doors, water, and electrical hookup, as well as extra battery power to run the facility.

- Procure battery bank

- Build facility for fabricating CEB machines

Cycle 4: May 1-May 30 Collection Cycle, $3210 - Optimize Production for Replicability

- Production facility optimization

- Produce replicable design for XYZ table

- Build second XYZ table prototype to prove the economics of fabrication of the XYZ table

- Make any rearrangements in fabrication facility to facilitate workfow

- Build additional accommodations for additional fabricators. We are planning on 4 new fabricator positions.

Step 4. Design and Fabrication

We have already built a prototype, which we discussed at our blog here. We posted the fabrication procedure pictures - CEB_Prototype_1_Fab. The design evolution for the prototype is documented at Worknets. The relevant technical drawings that we have to date are here. These drawings are not complete, so please contact us if you can help us with the drawings.

Design has 5 major components:

- Documentation of CEB Prototype 1 (shown above)

- XYZ table for automating fabrication - present work, Jan-Feb 2008

- Documentation of CEB Prototype 2

- Facility Design

- Final CEB design

At this point, we move into CEB Funding Cycle 1 to deliver the XYZ Torch Table for producing the CEB machine more effectively.

Social Enterprise Reviews

- Review of the social enterprise experiment by P2P Foundation

- Review by Samuel Rose of Social Synergy

- P2P Foundation review of the economic model

Economic Review

CEB may be set for a second renaissance. Cheap energy has put the emphasis on cement based construction for many decades. Scarcity driven by peak oil and political instability will combine to make low energy construction methods more attractive.

The biggest need is for a low energy stabilization method. While there are examples of buildings that have survive for many centuries, many required considerable maintenance. Others have decayed rapidly in modern times without constant recoating. One development that may make a huge difference for CEB's is enzyme stabilization. Products such as Permazyme 11X, EcoBric and others may make possible the low energy manufacture of bricks and blocks that have weather resistance approaching concrete. The enzyme products are nontoxice and relatively low cost. $40-$60 worth of Permazyme is supposed to stabilize enough earth for a large house.(Permazyme@$120/gal. stabilizes 150 cu yds) I have been unable to find any builders using these products for CEB(though EcoBric is aimed at that market) but there seems to be considerable experience stabilizing road bases. The manufacturers have concentrated on the road building market because of the money. After all, 1 or 2 liters for a house isn't much compared to 15 gallons per mile of road. The original patents seem to have expired, so it may be possible to come up with an open source recipe for the enzyme. It may not be an enzyme at all. The first product of this type came about when a vintner notice the the waste from wine-making hardened the soil where it was dumped.

An inexpensive low energy way to stabilze compressed earth combined with low cost mechanization could make CEB's a significant contributor to an ecological housing solution for the future.

Further Resources

Our program is unique in that we are producing both an open source product, and also developing an open source model for the enterprise itself. You may read a review of this novel organizational model at the P2P Foundation website by clicking here.

A good article on the CEB may be found at Wikipedia, Compresssed Earth Block. There are several good online books: click Earth at the left hand bar on this website.

- AECT - CEB press fabricator - [pages.sbcglobal.net/fwehman/]

- Powell and Sons - CEB press fabricator - [1]

- Gernot Minke - one of the world's leaders in earth construction - see [2] for thorough overview, including detailed soil testing procedures.

- Galvanized wire reinforced, earthquake resistant earth construction techniques publication - [3]

- Ronald Rael is an Architect, Author and Assistant Professor of Architecture at The University of California, Berkeley. He is the founder of EarthArchitecture.org, a clearing house of information on the subject. May be interested in our work.

- Compressed Earth Block Guide - [4]

- CEB, Manual of Production - [5]

- What can happen in earthquakes - [8] , [9] , [10]

- Other information - [11] , [12]

How about through-tie with rebar? We are considering this for double brick thickness walls. We could use technical help on this.

- Rebar can get very expensive in the developing world. The galvinized wire reinforcing is much lighter, (aka a shipping container from these guys as an examle - [13] , **probably could provide better resistance to earthquake, simular pricing to rebar per pound, and probably 5 times the support per pound of material) as well as not needing double thickness which cuts down on labor.

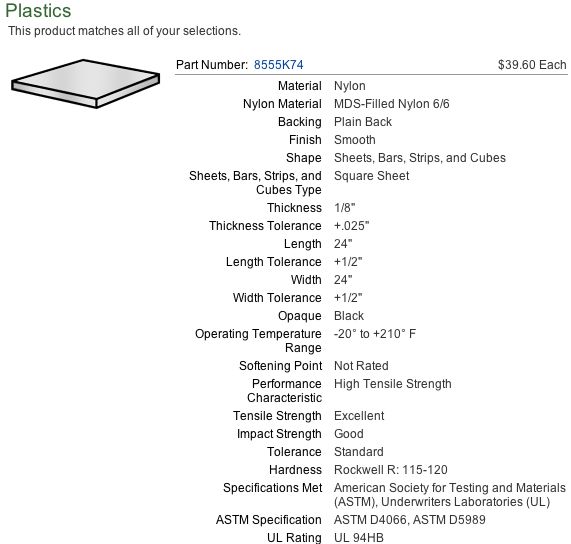

Bill of Materials

- Wear-resistant liner - MDS-Filled Nylon 6/6 from McMaster Carr

Public Responses

The following is a letter I recieved in response to a Countryside Magazine article (July/August 2008, pg 40) which discusses our building experiences at Factor E Farm. This reader has back-of-the-envelope plans for a manual CEB press. Manual presses are useful in places when labor is more accessible/cheaper than equipment. This letter also shows the general simplicity of the CEB-- the task at hand, compressing soil into bricks-- is not that complicated.