Upper Austria Green Biorefinery: Difference between revisions

No edit summary |

m (inserted links) |

||

| Line 16: | Line 16: | ||

[http://www.chisa.cz/2010/admin/contrib_get_abstract_edited.asp?id_02=1121 here] | [http://www.chisa.cz/2010/admin/contrib_get_abstract_edited.asp?id_02=1121 here] | ||

Within the project "Green Biorefinery Upper Austria" a demonstration plant for the separation of resources from grass silage was built up and operated near the biogas plant in Utzenaich (Upper Austria). The aim of the project, which includes the OÖ Bioraffinerie GesmbH, Joanneum Research Forschungsgesellschaft mbH and BiorefSys as partners, is to produce lactic acid and various amino acids from pressed silage juice. | Within the project [http://www.energytech.at/pdf/biorefinery_steinmueller.pdf "Green Biorefinery Upper Austria"] a demonstration plant for the separation of resources from grass [[silage]] was built up and operated near the [[biogas]] plant in Utzenaich (Upper Austria). The aim of the project, which includes the OÖ Bioraffinerie GesmbH, Joanneum Research Forschungsgesellschaft mbH and BiorefSys as partners, is to produce lactic acid and various amino acids from pressed silage juice. | ||

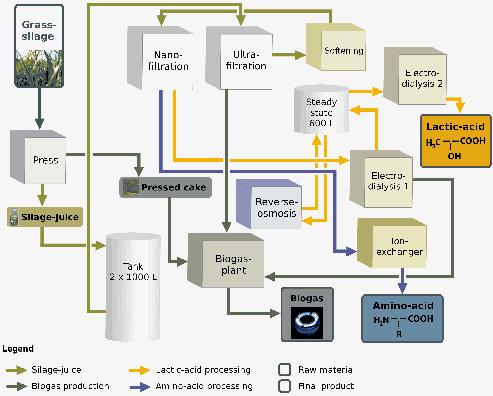

The juice is pressed from silage bales of farmers in the vicinity of the bio-refinery. The material varies from normal grass to special grass clovers, which contain higher amounts of potential resources. After sedimentation, the process (Figure 1) is started with the production of the acid containing streams. The first step is an ultrafiltration unit in which disturbing macromolecules and proteins can be separated from the product stream. After this first clarification step the stream is fed into a nanofiltration unit. This standard unit operation allows the separation of phases enriched in amino acids and phases enriched in lactic acid. The divided streams are processed in two separated ways. The phase loaded with amino acids is cleared in an ion exchange street. Streams having concentrated amounts of specific amino acids fractions are produced in this step. The lactic acid stream is fed into two serial electrodialysis units. In the first unit the stream is desalinated. The varying amount of salts in the feed can be compensated with different dwell times. The salts are migrating into the concentrate cycle, which is the waste stream of this step. The desalinated stream is fed into a reverse osmosis plant to increase the amount of lactic acid and to reduce the volume to be pumped. The concentrated stream is the feed for the second electrodialysis unit, which separates the lactic acid from the diluate. Due to its structure, the acid is migrating slowly. The transport can be enhanced by increasing the current density and the dwelling time in the tanks. One of the most important advantages of the “Green Biorefinery” is that no waste is produced. All of the accumulated by-products, i.e. press-cake, ultrafiltration-retentate and electrodialysis concentrate, can be used as substrates in the adjacent biogas plant Utzenaich. The other product free streams are recycled in the “Green Biorefinery” itself. | The juice is pressed from silage bales of farmers in the vicinity of the bio-refinery. The material varies from normal grass to special grass clovers, which contain higher amounts of potential resources. After sedimentation, the process (Figure 1) is started with the production of the acid containing streams. The first step is an ultrafiltration unit in which disturbing macromolecules and proteins can be separated from the product stream. After this first clarification step the stream is fed into a nanofiltration unit. This standard unit operation allows the separation of phases enriched in amino acids and phases enriched in lactic acid. The divided streams are processed in two separated ways. The phase loaded with amino acids is cleared in an ion exchange street. Streams having concentrated amounts of specific amino acids fractions are produced in this step. The lactic acid stream is fed into two serial electrodialysis units. In the first unit the stream is desalinated. The varying amount of salts in the feed can be compensated with different dwell times. The salts are migrating into the concentrate cycle, which is the waste stream of this step. The desalinated stream is fed into a reverse osmosis plant to increase the amount of lactic acid and to reduce the volume to be pumped. The concentrated stream is the feed for the second electrodialysis unit, which separates the lactic acid from the diluate. Due to its structure, the acid is migrating slowly. The transport can be enhanced by increasing the current density and the dwelling time in the tanks. One of the most important advantages of the “Green Biorefinery” is that no waste is produced. All of the accumulated by-products, i.e. press-cake, ultrafiltration-retentate and electrodialysis concentrate, can be used as substrates in the adjacent biogas plant Utzenaich. The other product free streams are recycled in the “Green Biorefinery” itself. | ||

Revision as of 15:57, 28 February 2011

Main > Materials > Bioplastics

Membrane based production of lactic acid and amino acids – green biorefinery Upper Austria

J. Ecker, 1M. Harasek

Vienna University of Technology, Institute of Chemical Engineering, Getreidemarkt 9/166-2, 1060 Wien, Tel.: +43-1-58801-15978,

e-mail: jecker@mail.zserv.tuwien.ac.at;

Vienna University of Technology, Institute of Chemical Engineering, Getreidemarkt 9/166-2,

e-mail: michael.harasek@tuwien.ac.at

source: here

Within the project "Green Biorefinery Upper Austria" a demonstration plant for the separation of resources from grass silage was built up and operated near the biogas plant in Utzenaich (Upper Austria). The aim of the project, which includes the OÖ Bioraffinerie GesmbH, Joanneum Research Forschungsgesellschaft mbH and BiorefSys as partners, is to produce lactic acid and various amino acids from pressed silage juice.

The juice is pressed from silage bales of farmers in the vicinity of the bio-refinery. The material varies from normal grass to special grass clovers, which contain higher amounts of potential resources. After sedimentation, the process (Figure 1) is started with the production of the acid containing streams. The first step is an ultrafiltration unit in which disturbing macromolecules and proteins can be separated from the product stream. After this first clarification step the stream is fed into a nanofiltration unit. This standard unit operation allows the separation of phases enriched in amino acids and phases enriched in lactic acid. The divided streams are processed in two separated ways. The phase loaded with amino acids is cleared in an ion exchange street. Streams having concentrated amounts of specific amino acids fractions are produced in this step. The lactic acid stream is fed into two serial electrodialysis units. In the first unit the stream is desalinated. The varying amount of salts in the feed can be compensated with different dwell times. The salts are migrating into the concentrate cycle, which is the waste stream of this step. The desalinated stream is fed into a reverse osmosis plant to increase the amount of lactic acid and to reduce the volume to be pumped. The concentrated stream is the feed for the second electrodialysis unit, which separates the lactic acid from the diluate. Due to its structure, the acid is migrating slowly. The transport can be enhanced by increasing the current density and the dwelling time in the tanks. One of the most important advantages of the “Green Biorefinery” is that no waste is produced. All of the accumulated by-products, i.e. press-cake, ultrafiltration-retentate and electrodialysis concentrate, can be used as substrates in the adjacent biogas plant Utzenaich. The other product free streams are recycled in the “Green Biorefinery” itself.

The product streams will be used for different applications. For example, there are uses of lactic acid in the animal food industry or in the chemical industry as a precursor of ethyl lactate. The amino acids are used in the food industry or in cosmetics and pharma industry. This process still needs improvements to achieve high product quality to be less dependent on the raw materials. In the 30 month duration of the project the procedure will be optimized and, if necessary, changes are made in the build up to produce economic products.

Within this work, first process results of the electrodialysis systems for the lactic acid production will be presented. Additionally, initial system performance and first operating experiences during continuous campaigns will be reported.