Industrial Robot Systems Engineering Diagram: Difference between revisions

No edit summary |

No edit summary |

||

| Line 2: | Line 2: | ||

To start, the power supply takes electrical power from external sources and feeds current at different voltages to the various parts of the industrial robot. Particularly, the sensor array, which can be comprised of different devices such as lasers to determine distance, generally uses a small voltage and perceives the surroundings of the industrial robot; this information is transmitted as an analog signal to the microcontroller; the microcontroller takes this analog signal and converts it to a digital signal using an analog-to-digital converter contained within. Using these digital signals as well as those from the computer interface (human-controlled programming allows various functions and movements to be recorded in the memory of the microcontroller), the microcontroller sends digital signals to the motor driver, which transmits differing levels of electrical power to the motors according to the microcontroller's command. As the motors rotate their shafts, a shaft encoder analyzes the specific speed of the shaft rotation (perceived as an analog signal) and transmits this information to the microcontroller as a digital signal; this shaft speed information allows the microcontroller to compensate for differing loads on the motors hence control the actual motor shaft movement with a high degree of accuracy; this feedback structure is known as a closed-loop control system. | To start, the power supply takes electrical power from external sources and feeds current at different voltages to the various parts of the industrial robot. Particularly, the sensor array, which can be comprised of different devices such as lasers to determine distance, generally uses a small voltage and perceives the surroundings of the industrial robot; this information is transmitted as an analog signal to the microcontroller; the microcontroller takes this analog signal and converts it to a digital signal using an analog-to-digital converter contained within. Using these digital signals as well as those from the computer interface (human-controlled programming allows various functions and movements to be recorded in the memory of the microcontroller), the microcontroller sends digital signals to the motor driver, which transmits differing levels of electrical power to the motors according to the microcontroller's command. As the motors rotate their shafts, a shaft encoder analyzes the specific speed of the shaft rotation (perceived as an analog signal) and transmits this information to the microcontroller as a digital signal; this shaft speed information allows the microcontroller to compensate for differing loads on the motors hence control the actual motor shaft movement with a high degree of accuracy; this feedback structure is known as a closed-loop control system. | ||

=Controller= | |||

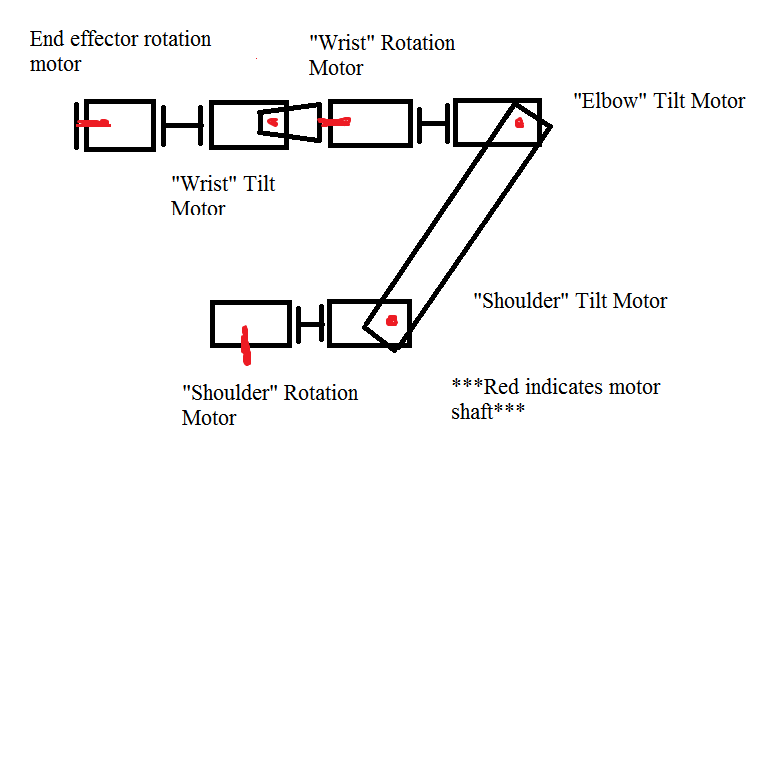

[[Image:6axisrobotmech.png]] | |||

=Mechanical Concept= | |||

[[Image:6axisrobotmech.png]] | |||

[[Category:Systems Engineering]] | |||

Revision as of 08:37, 30 April 2011

To start, the power supply takes electrical power from external sources and feeds current at different voltages to the various parts of the industrial robot. Particularly, the sensor array, which can be comprised of different devices such as lasers to determine distance, generally uses a small voltage and perceives the surroundings of the industrial robot; this information is transmitted as an analog signal to the microcontroller; the microcontroller takes this analog signal and converts it to a digital signal using an analog-to-digital converter contained within. Using these digital signals as well as those from the computer interface (human-controlled programming allows various functions and movements to be recorded in the memory of the microcontroller), the microcontroller sends digital signals to the motor driver, which transmits differing levels of electrical power to the motors according to the microcontroller's command. As the motors rotate their shafts, a shaft encoder analyzes the specific speed of the shaft rotation (perceived as an analog signal) and transmits this information to the microcontroller as a digital signal; this shaft speed information allows the microcontroller to compensate for differing loads on the motors hence control the actual motor shaft movement with a high degree of accuracy; this feedback structure is known as a closed-loop control system.