Steam Engine Build/Bump Valve Pin: Difference between revisions

No edit summary |

|||

| Line 23: | Line 23: | ||

* Threaded end = 0.500" | * Threaded end = 0.500" | ||

From rod stock of steel 0.250" in diameter, cut off a length equal to 0.875" (7/8"). | Instructions: | ||

* From rod stock of steel 0.250" in diameter, cut off a length equal to 0.875" (7/8"). | |||

* Thread 0.5". | |||

* Make two. | |||

[[Category:Steam Engine]] | [[Category:Steam Engine]] | ||

Revision as of 17:00, 30 May 2011

Main > Energy > Steam Engine

Steam Engine Build Instructions

Description

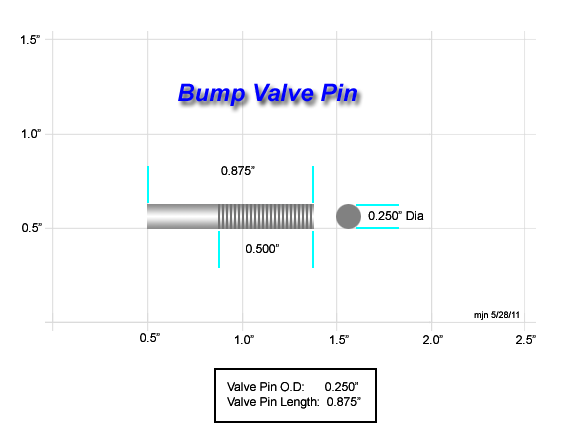

The bump valve pin is threaded on one end to be screwed into the piston head. As the piston nears top dead center, the pin (there are actually two of them) push on the valve causing it to open (ie, it bumps it). Steam is admitted into the cylinder clearance increasing steam pressure in the cylinder to boiler pressure level. The piston moves past top dead center by momentum from a flywheel on the crankshaft. As it starts to move away, the valves close. Steam expands pushing the piston, thus starting another engine cycle.

The bump valve pin takes a lot of abuse since it bangs away at the valves many times a minute. It should be made from good, tough steel.

The exact distance that the valve should be opened during steam admission is something of an educated guess at this stage. The current specification of 1/8" may need to be either increased or decreased. The Steam Engine Design makes provisions for swapping pins in and out, cut to different lengths as needed. New pins are easy to make, given a quantity of quarter inch steel rod.

Drawing

Instructions

Design Specifications:

- Clearance = 0.250"

- Valve opening = 0.125"

- Threaded end = 0.500"

Instructions:

- From rod stock of steel 0.250" in diameter, cut off a length equal to 0.875" (7/8").

- Thread 0.5".

- Make two.