Ironworker/Research Development: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 12: | Line 12: | ||

=From SMJ Tsakok= | =From SMJ Tsakok= | ||

Adding a metal shear element to [[Ironworker Prototype I]] | Adding a metal shear element to [[Ironworker Prototype I]]: | ||

[[Image:holepuncher1.jpg|500px]] | [[Image:holepuncher1.jpg|500px]] | ||

[[Image:holepuncher2.jpg|500px]] | [[Image:holepuncher2.jpg|500px]] | ||

Revision as of 19:02, 31 August 2011

| Ironworker | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Concepts

- 120 ton for up to 1.5" holes in 1" metal

- Can be based on the existing Holepuncher Prototype I design

- Shear for 8-12" of 1" steel

- Angle cutter for up to 6x6 angle

- DIY shear blade - made from hardening of mild steel, at $40 in materials

- May involve Induction Furnace for hardening

From SMJ Tsakok

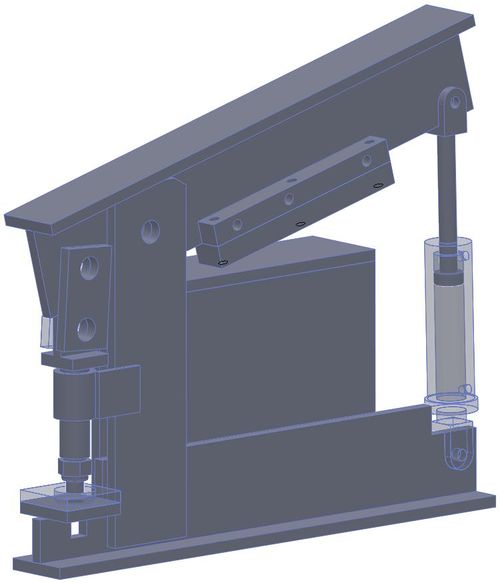

Adding a metal shear element to Ironworker Prototype I: