Steam Engine Construction Set: Difference between revisions

| Line 194: | Line 194: | ||

Electronic Solenoid Valve Info: http://www.gwlisk.com/tech_info.html | |||

http:// | |||

=Tooling Requirements= | =Tooling Requirements= | ||

Revision as of 17:15, 20 January 2009

Introduction

Steam engines are a robust energy source which played a main role in the industrial devolution, and may now be a viable candidate as an engine of the post-industrial revolution. Tinytech in India manufactures steam engines for various industrial swadeshi applications, primarily in India. We believe that steam engines, coupled to flash steam generators, are also relevant as an appropriate technology choice in the 'developed' world. As such, we are proposing an open source steam engine project, to deliver an appropriate technology, modern steam engine:

- Open design

- Scalable in power from 5 to 100 horsepower

- May utilize electronic valving for mechanical simplification

- May be coupled direcly to linear dynamo - feasibility study required

In particular, Factor e Farm is interested in utilizing these steam engines in the LifeTrac line of tractors, cars, and solar turbine electrical generators.

Design

Link title==Engine==

Typical Engines

Typical steam engine cylinders are made from cast iron. (What is the best metal to use for a steam engine?) Given that water is the working fluid, lubrication is required in the cylinder. (Is there any way to prevent corrosion otherwise?)

- Cylinder - cylinder is made from cast iron.

- To cast this cylinder from scrap iron, use a (how many?) pound melt, and use a simple melting furnace such as (here?)

The simplest way to cast a cylinder

Green Steam Engine

An alternative engine design that may be worthy of further evaluation can be found [1] here. It looks as though o-rings are used in place of traditional tight tolerance cast iron cylinder boring. Presumably this method is only good for low pressure and temperature steam. The linkage and valve system is highly innovated and would require no precision machining.

- Discussion of the Green steam engine:http://www.alternative-energy-news.info/green-steam-energy/ It does indeed seem that the o-ring method of sealing is incapable of handling high steam temps and pressures and the design is therefore inherently inefficient.

- Marcin says: I looked at this in detail 2 years ago, and purchased plans. When I asked for references of people who built this engine, the inventor did not provide me with any. I became suspicious about the effectiveness of the engine. Since then, I've heard reports from several sources that longevity and performance are questionable. In summary, if this worked as stated, we would see a large number of implementations on the internet. Since these are not to be seen, it does not appear to be a promising design.

Steam Engine History:

http://www.egr.msu.edu/~lira/supp/steam/

A History of the Growth of the Steam Engine: [2]

A Catechism of the Steam Engine:[3]

Steam Engine Primers/Groups:

http://www.pioneer.net/~carlich/RSE/RSEprimer.html

http://www.the-nerds.org/Steam-101.html

Promising forum with large library of working steam engine plans: http://www.paddleducks.co.uk/

Engine Plans/Products:

http://www.pioneer.net/~carlich/RSE/RSEengines.html

http://www.nearfutures.com/products.htm

http://www.greensteamengine.com/products.htm

Triple Expansion Steam Engine Prints: http://www.carferries.com/triple/

Lindsey Publications:http://www.lindsaybks.com/prod/sub/engines.html

http://quasiturbine.promci.qc.ca/Presse/SteamMuller050721.pdf

These guys claim 30% efficiency on their non compunding multi cylinder steam engine http://www.energiprojekt.com/?product

*3kW steam engine for $1375: http://www.thesustainablevillage.com/servlet/display/products/byCat/71/441/2557/

Lots of Plans: http://www.john-tom.com/html/SteamPlans.html

A nice simple doubel engine plan: http://openfarmtech.org/images/e/e0/MichelNiggelTwin.pdf

Misc:

Vegetable Oil Based Lubricant:http://www.steamenginelube.com/chelesic.htm

Homebrew Steam Engine Generator:http://www.otherpower.com/steamengine.shtml

Steam Engine Manuf. Links: http://cedesign.net/steam/steam-links1.htm

Oil Free Steam Engine Design for Vehicles: http://six6.region-stuttgart.de/sixcms/media.php/773/23_Platell_P.pdf

Flash Steam Engine, Could this be advantageous http://www.huzar-power.com/steam_engines/revival/flash_steam.htm

Engineering Specs:

Nick R. says, what are the limits to lathe boring diameters in cast iron? This [4] method of construction looks simple and attractive if it could be scaled up enough?

Boiler

A simple boiler implementation involves a Babington_Burner heating the inside of a 6 inch metal pipe of 1/8" wall thickness. A 100 foot long coil of 1/2 inch steel tubing is placed inside this coil, and an electronically-controlled Valve delivery system (note: in steam engine case, the 'solar boiler' in last link is replaced by the above 100-foot coil of steel tubing.

Materials

- Stainless steel tubing at McMaster Carr, $130 for 100 feet of 1/2" tubing - type 304 stainless - item number 8989K67 at http://mcmaster.com

- 200 psi pressure relief valve - source?

Boiler Fuel:

For transportation vehicles some biomass fuel energy densification is required. Pyrolisis fuels without elaborate processing look prmoising here is a brief summary of some methods http://www.ars.usda.gov/sp2UserFiles/Program/307/biomasstoDiesel/RobertBrown&JenniferHolmgrenpresentationslides.pdf

http://www.biomasscombustion.com/horizontal_grate_technology.htm

Stationary applications can probably get by with a simple style grate biomass boiler. http://www.biomasscombustion.com/horizontal_grate_technology.htm

Design Evolution

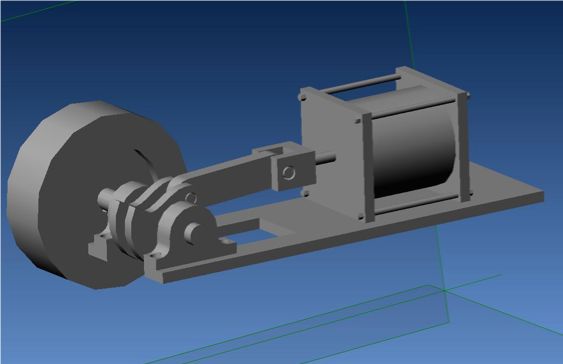

- Initial design, 1.8.09 -

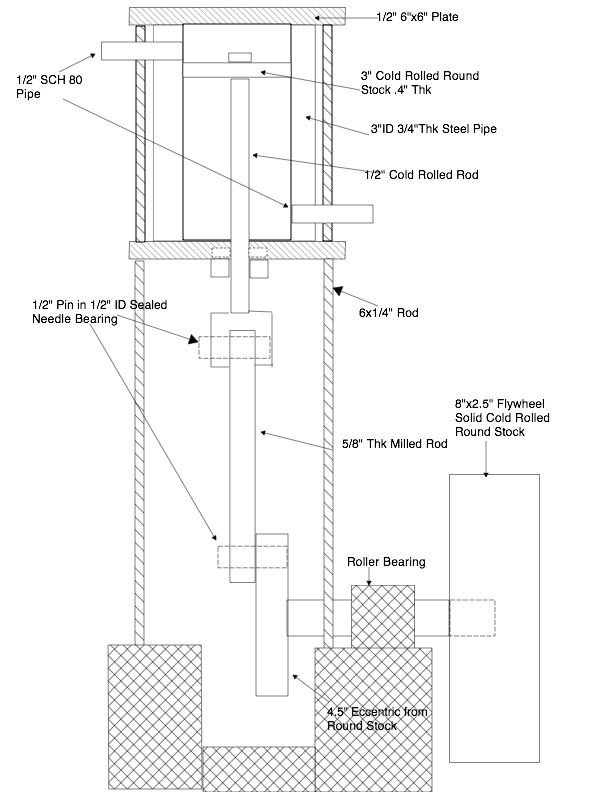

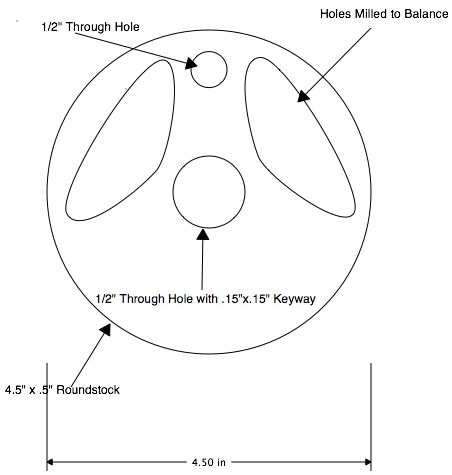

Bill Of Materials To Date

QTY Description Price Location 1 Cylinder 38.03 http://www.discountsteel.com/index.cfm/go/main.itemDisplay/itemID/45.htm 1 Piston 3" x 5/8" Cold rolled Steel 9.97 http://www.discountsteel.com/index.cfm/go/main.itemDisplay/itemID/13.htm 1 Shaft 1" 13.01 http://www.discountsteel.com/index.cfm/go/main.itemDisplay/itemID/13.htm 2 Plate 1/2"x6"x6" 17.71 http://www.discountsteel.com/index.cfm/go/main.itemDisplay/itemID/4.htm 1 Flywheel 8"x2.5" Cold Rolled Steel 74.3 http://www.discountsteel.com/index.cfm/go/main.itemDisplay/itemID/13.htm 1 Eccentric 4.5" x .5" Cold rolled 13.95 http://www.discountsteel.com/index.cfm/go/main.itemDisplay/itemID/13.htm 2 .5" Dia Pin 1.75" Long 6.29 http://www.discountsteel.com/index.cfm/go/main.itemDisplay/itemID/13.htm 1 Lower Connecting rod 5/8"x1"x6" 9.91 http://www.discountsteel.com/index.cfm/go/main.itemDisplay/itemID/11.htm 4 3/4"x1.5' Threaded Rod 14.64 http://www.grainger.com/Grainger/items/2GRR4?cm_mmc=Google%20Base-_-Fasteners-_-Bolts-_-2GRR4 Baseplate TBD Stuffing Box TBD 1 6' Sch 80 Steam Pipe 43.7 http://www.amazon.com/dp/B001NPLLW2/ref=sr_1_3?ie=UTF8&m=AH1JDG368QYFS

TOTAL 241.51

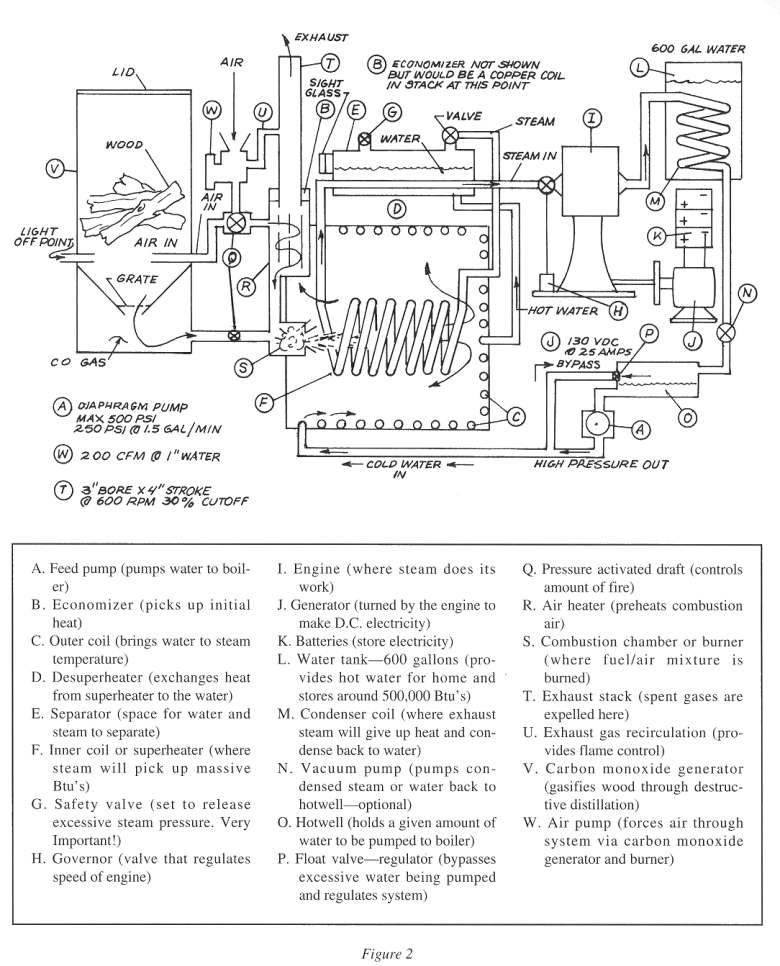

Example of Fully Integrated Steam Energy System

Description of this system by author and excellent background info on homepower steam http://www.fastonline.org/CD3WD_40/JF/JF_OTHER/BIG/Reciprocating%20Steam%20Engine.pdf

Apparently Skip Goebel thinks similar to me about electronically controlled steam engines taken from http://www.mail-archive.com/sustainablelorgbiofuel@sustainablelists.org/msg01818.html

Fwd from [EMAIL PROTECTED]:

Two things that I see on the very near horizon that puts steam back on top both efficiency and cost wise in bio fuels.

First is catalized refractory. For years, I have been getting a wonderful

catalytic reaction using 'cera-blanket' as a liner in my wood burning fireboxes. Now, by layering a layer of perforated firebrick, behind that a layer of cerablanket, behind that thin steel plate that is perforated and an airgap behind that with casing on the other side. This allows air to be pumped from the casing thru the blanket and then thru the perf brick. We are talking small amounts here of air, but enough to ignite and glow. It is similar to indoor propane heaters used today(ventless).

With such a reaction between the esters and carbon monoxide burning in such

a way as to really put out the i.r. rays, The firebox is improved in many ways. Including smaller amount of headroom from fuel pile to cieling. This allows fuel pile to be surrounded by the high radiation/refraction refractory. In doing so, the fuel pile distills quite easily, and requires far less incoming air thru the grate which is a big source of nox. The gasses driven off the fuel pile can now be reignited in a controlled situation and where most beneficial.

Of even bigger benefit, is this kind of firebox can utilize wood 3' or even

longer. This signifigantly reduces material handling energy and cost (hogging). It also makes hand firing feasable. That means a lot in third world countries.

The biggest news for steam is electric valves. Finally, they are

commercially available. Volvo will put them out in a year. Valve timing on a piston type steam engine is everything. Without getting too fancy already, I manufacture engines that eat far less steam than a turbine up to about 500hp. The cost is less than half also.

If I can operate the valve via electric sylinoid instead of mechanical, I

have infinite adjustment on cutoff and expansion which allows for perfect governing and a consumption rate of 10-15lbs per hp, vs 50-70 on a turbine. Again, this is in the up to 500hp bracket, but in the real world, biomass falls into this catagory. Only the big lumbermills do it larger and they are not everywhere. And....they are more user friendly and cheaper.

I am making the statement now that the catalytic refractories and the

electric valving will become the foundation for new technologies in the combustion of bio fuels. If you do the math, you will see that the fuel rates come close to diesel engines, but without all the hassles. Boilers are more versatile as diesel engines are limited to mainly motive powers and electricity is the main one. While a boiler can give you the means of production and manufacturing. This means a genuine return on investment.

...it could be that the grant process will become history. :)

Skip Goebel Sensible Steam International www.sensiblesteam.com www.apin.com.pe

Electronic Solenoid Valve Info: http://www.gwlisk.com/tech_info.html

Tooling Requirements

Metal Casting

- see Foundry for more details

Waste vegetable oil furnace design http://www.backyardmetalcasting.com/oilburners03.html Foundry.pdf Pattern_Making.pdf

www.budgetcastingsupply.com http://www.metalwebnews.com/howto/furnace/furnace.html www.creativecastingco.com www.host33.com/casting www.backyardmetalcasting.com www.emainc.com/radnor/sand.htm http://oak.cats.ohiou.edu/~dw120996/..._of_metals.htm

Lathe

- Romig bed lathe type - from Multimachine -

- Simple prototype, $486 in materials BOM:

- 2 bearings, $50

- 2 mouning plates, 1/2"x6" angle - $40

- 4 Shaft Collars - $20

- 2" shaft - $20

- DOM tubing, 3", 2" ID - $15

- 8 3/4" bolts for table - $16

- Chuck plate - $40

- Bolts for chuck - $20

- Nuts and bolts for DOM - $5

- XY table - $70 off shelf at Enco - [5]

- Tool post - $10

- table plate - $30

- 2 bags of cement, 80 lb each - $20

- sand, gravel - $10

- TOTAL - $316

- High performance, 2/1000" accuracy with proper technique, stock parts, 1000 lb radial and 200 lb axial load capacity

- Romig bed lathe type - from Multimachine -

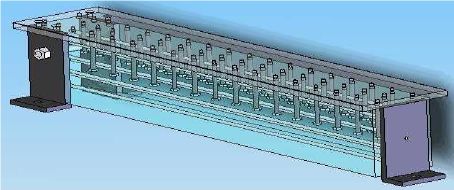

Flash Steam Generator

- Coil bending jig - $400

- Stainless steel coil, 150 feet - $200

- Babington fittings and metal - $100

- Dremel tool - $40

- Dremel micro drill press - $40

Electrical Generator

Open Source Steam

Steam power is not taught in general. For mastering this topic, we need a Steam Power Reading List.

- I have some of this material from Tom Kimmel, of Kimmel Steam Power

- Mike Brown offers a reading list here

Letters and Communications

Letter to VK Desai of Tinytech Plants -

Dear VK,

Can you share your knowledge of steam power with us?

In order to make our solar turbine a success, we need to build the steam engine at low cost - in house. If I do my own labor, use our machine shop, and use casting in house, then the price for the engine parts should be about $150 for a 3 hp engine. Do you think that is realistic?

Please share with me your basic design. Simple drawings on the back of an envelope would do. I am smart at studying design. Please just give me the essentials and material specifications.

Please respond, or put your notes up directly at:

http://openfarmtech.org/index.php?title=Steam_Engine_Construction_Set

If you have any pictures of steam engines in fabrication, please share.

Sincerely,

Marcin

Development Team

- Nick Raaum - Project Manager. He works at a coal power plant, but his visions are different.

- Marcin Jakubowski