LifeTrac III/Manufacturing Instructions: Difference between revisions

Jump to navigation

Jump to search

Tom Griffing (talk | contribs) |

Tom Griffing (talk | contribs) |

||

| Line 99: | Line 99: | ||

==Parts Fabrication== | ==Parts Fabrication== | ||

* The purpose of this section is to prepare the components for final assembly. This includes cutting steel into required | * The purpose of this section is to prepare the components for final assembly. This includes cutting steel into required | ||

====¼” x 4" x 4" Steel Tube==== | ====¼” x 4" x 4" Steel Tube==== | ||

Revision as of 10:37, 7 November 2011

| LifeTrac III | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

| ||||||||||||||||||||||||||

Overview

LifeTrac is a low-cost, multipurpose open source tractor. It serves as a workhorse backbone for many of GVCS technologies.

Featuring a modular design and detachable PowerCube units, it has the ability to rapidly switch between a variety of GVCS machines via the QA Plate. The machine is overbuilt with a focus on lifetime design and ease of repair.

Four hydraulic motors provide skid steer power to the wheels, and a unique chain tread system enables navigation of fairly extreme terrain.

Preparation

Safety

- Hearing Protection

- Eye Protection

- Steel Toe Boots

- Welding

- Gloves

- Hood

- Apron/Jacket

Workspace

This section describes the various workspace areas that we have found to be useful in fabricating the LifeTrac. It is provided as a suggestion for preparing your work area.

- Storage: For raw steel and parts

- Cutting Area: For use with cutting torch - Made from non-flammable materials

- Welding Table: Usually steel, suitable for use with arc welder (MIG, TIG, stick, etc)

- Ventilation for cutting / welding areas

Tools

- Welder

- Angle Grinder

- Hand Tools

- Crescent wrench

- Socket set

- Hammer

- Metal Cutting Tools

- Bandsaw

- Chopsaw

- Torch

- Paint Tools

- Gravity Fed Paint Sprayer

- Air compressor

Cut Sheet

- This list contains instructions for cutting the raw steel into pieces for assembly. Most will require further cuts before being ready for assembly.

3/8” Thick, 8" Plate

- 4 @ 12 1/2"

1/2" Thick, 4" Plate

- 6 @ 6"

- 8 @ 4" (cut each diagonally for 16 triangles)

1/2" Thick, 8" Plate

- 4 @ 6"

- 8 @ 10"

1/2" Thick, 10" Plate

- 8 @ 10"

- 4 @ 6 3/4"

1/2" Thick, 12" Plate

- 5 @ 12"

1" Thick, 8" Plate

- 4 @ 4 1/2"

1/2” Thick, 4" x 6" Angle

- 4 @ 6"

¼” Thick, 2 3/8" Dia Steel Tube

- 1 @ 4 1/2"

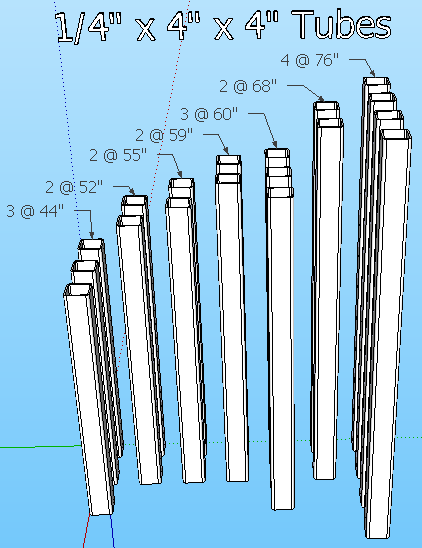

¼” Thick, 4" x 4" Steel Tube

- 3 @ 44"

- 2 @ 52"

- 2 @ 55"

- 2 @ 59"

- 3 @ 60"

- 2 @ 68"

- 4 @ 76"

5/16” Thick, 2 1/2" Dia Steel Tube

- 4 @ 5"

3/8” Thick, 3" x 6" Steel Tube

- 1 @ 45"

- 2 @ 100"

1 7/8" Shaft

- 4 @ 26"

- 1 @ 56"

Parts Fabrication

- The purpose of this section is to prepare the components for final assembly. This includes cutting steel into required

¼” x 4" x 4" Steel Tube

- Verify the following 4" x 4" tubes have already been cut:

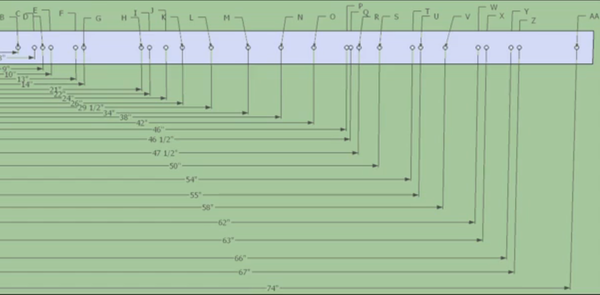

- To simplify hole placement, here is an image of a jig (click to enlarge):

Tube Drilling

- 3 Lower cross tubes, 60" long

- Drill holes at 14", 46"

- Rotate 90 degrees, drill holes at 2", 10", 50", 58"

- 2 Bottom Inner North-South tubes, 76" long

- Drill holes at 6", 9", 13", 30", 63", 67", 70"

- Rotate 90 degrees, drill holes at 2", 10", 50", 58"

- 2 Bottom Outer North-South tubes, 76" long

- Drill holes at 9", 13", 63", 67"

- Rotate 90 degrees, drill holes at 2", 34", 58 1/2" 62", 74"

- 2 Front Vertical tubes, 55" long

- Drill holes at 6", 50"

- Rotate 90 degrees, drill holes at 2", 46"

- 2 Middle Vertical tubes, 52" long

- Drill holes at 6", 24", 50"

- Rotate 90 degrees, drill holes at 2", 46"

- 2 Rear Vertical tubes, 59" long

- Drill holes at 2", 21", 29 1/2", 47 1/2", 54"

- Rotate 90 degrees, drill holes at 6", 50"

- 2 Top North-South tubes, 68" long

- Drill holes at 6", 22", 62"

- Rotate 90 degrees, drill holes at 2", 26", 66" and a 2 3/8" hole @ 48" (with cutting torch)

- 3 Top Cross tubes, 44" long

- Drill holes at 6", 38"

- Rotate 90 degrees, drill holes at 2", 42"

Assembly

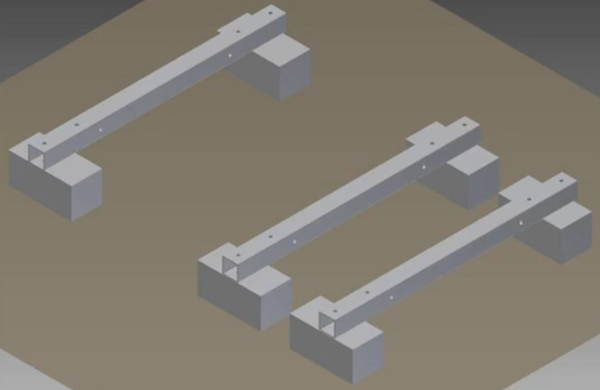

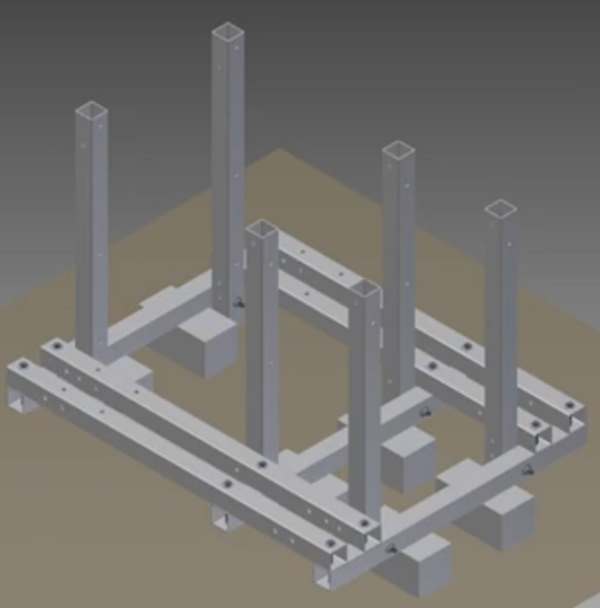

- Use 6 blocks to support the 3 bottom cross members

- Place the 4 bottom North-South members on bottom cross members, secure loosely with 9 1/2" bolts, washers and lock nuts.

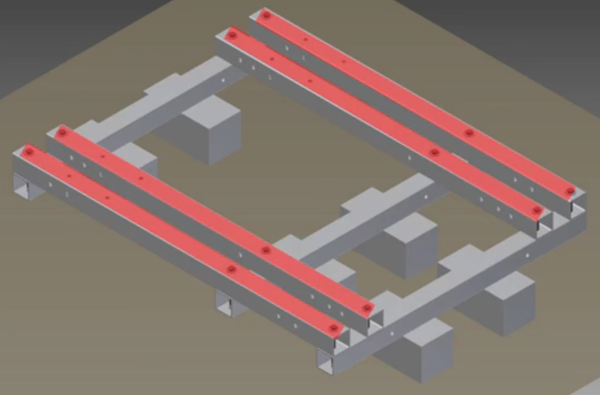

- Align the 6 Vertical members with holes in the lower frame, secure loosely with 9 1/2" bolts, washers and lock nuts.

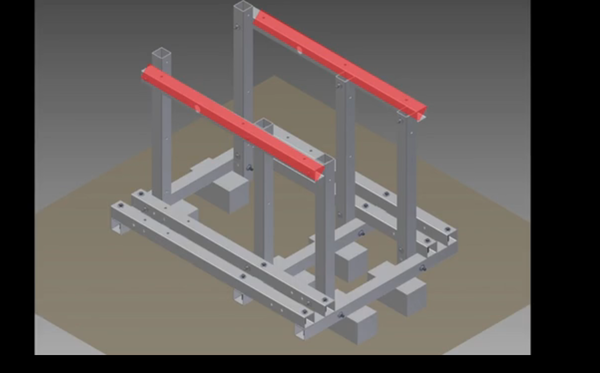

- Align the 2 Top North-South members with upper holes in the vertical members, secure loosely with 9 1/2" bolts, washers and lock nuts.

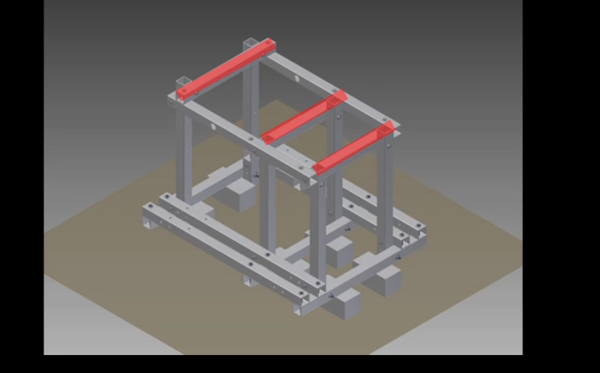

- Align the 3 Upper Cross members with holes in the upper North-South members, secure with 9 1/2" bolts, washers and lock nuts.

- Tighten all bolts / nuts.