Terminal Case: Difference between revisions

| Line 3: | Line 3: | ||

Version 4: | Version 4: | ||

Screw fastening would reduce the mounting volume of the terminal case considerably. But the trick is enabling screw fastening while retaining the ability to use C-Clamp compression too. | Screw fastening the lid would reduce the mounting volume of the terminal case considerably. But the trick is enabling screw fastening while retaining the ability to use C-Clamp compression too. | ||

The cable glands are fine but there's a mounting issue where the aluminum is too thick for the short mounting thread of the cable gland. Also a multi-cable issue associated with fact that a cable gland can only seal properly with a single cable. | The cable glands are fine but there's a mounting issue where the aluminum is too thick for the short mounting thread of the cable gland. Also a multi-cable issue associated with fact that a cable gland can only seal properly with a single cable. | ||

Revision as of 07:53, 8 December 2012

Introduction

Version 4:

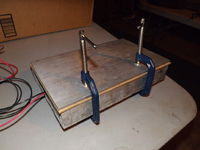

Screw fastening the lid would reduce the mounting volume of the terminal case considerably. But the trick is enabling screw fastening while retaining the ability to use C-Clamp compression too.

The cable glands are fine but there's a mounting issue where the aluminum is too thick for the short mounting thread of the cable gland. Also a multi-cable issue associated with fact that a cable gland can only seal properly with a single cable.

Welding technique: definitely weld the outside seams of the case because butt welds are far more straightforward than internal fillet welds. This also prevent slag from interfering with the electronics.

PCB Mounting technique: use spacers between the bottom of the PCB and the insulator plate so that short-circuiting is far less likely from any conductive thing getting down there.

Version 3:

File:Terminalcase35.jpg File:Terminalcase36.jpg

The objective is a waterproof, corrosion-resistant, chemical-resistant, impact-resistant, thermo- resistant, EMP-resistant, lightweight, accessible, versatile, modular container for electronics and other hardware.

Materials

Aluminum Plate 1/4" x 7" (Speedymetals)

Aluminum Bar 1/4" x 3" (Speedymetals)

Pure Tan Gum Rubber 1/8" x 12" x 24"

Aluminum Plate 1/4" x 7" x 72" OR Aluminum Plate 1/4" x 12" x 36"

Pure Tan Gum Rubber 1/8" x 12" x 24"

Build Documentation

Old Info

Version 2 with screw mounting: