Chris Bassett Log: Difference between revisions

No edit summary |

No edit summary |

||

| Line 1: | Line 1: | ||

[[File:Torch_Diagram.png]] | |||

[[File:Torch_Diagram | |||

=Tue Jul 16, 2013= | =Tue Jul 16, 2013= | ||

Revision as of 23:36, 18 July 2013

Tue Jul 16, 2013

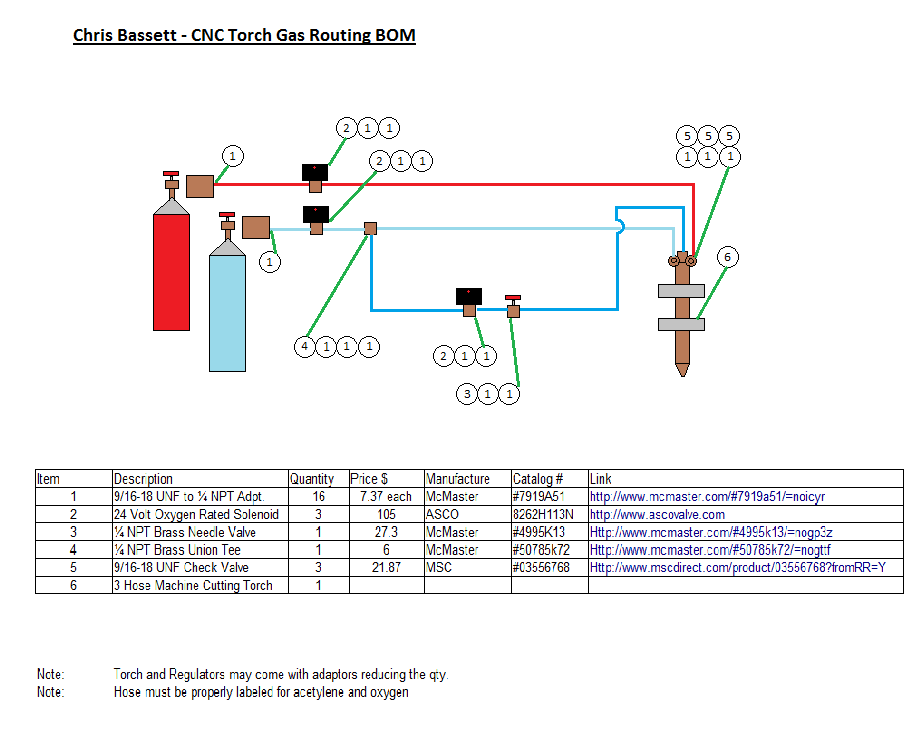

Created this to work off of and explain how the torch head functions (and to start filling in a BOM)

Oxygen Feed Solenoid: Got solenoid voltage from Paul Log. Actuation will be 24 volts coming from the heater circuit of the RAMPS board. Will need to check the current draw...

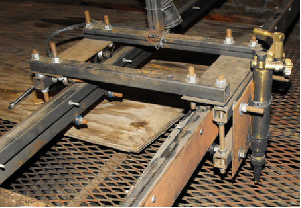

Torch Head Mounting: The end improvements from the first design should be getting the flow controls off the moving gantry. Inspection of torch head shows 1/2 NPT threads for a victor brand torch head cutting nozzle. However, the internal routing of gas flows means that the cutting nozzle cannot connect to any old manifold. Dissembling the rest of the torch, all internal connections are standard NPT sizes 1/8, 1/4, 1,2; so it looks like the a torch head can be disassembled to move the injection and mixing stages.

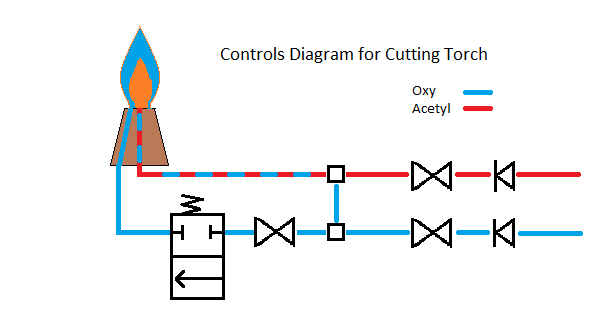

The flow is the same as the controls diagrahm, I'll spec the threads on the parts later.

If a torch like this is used, the manifold between 1 & 2 could be easily connected to a "dummy connector" and bolted to the gantry.

Mon Jul 15, 2013

Learned out to work GIT HUB to access file repositories. Need to download application. A tutorial can be found here: https://help.github.com/articles/fork-a-repo

The application can be found here: https://help.github.com/articles/set-up-git

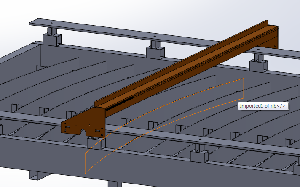

Checked that the solid works file loaded - successful. Will review in detail later

Researched Prior Work. Will build upon prior torch mounting systems of hose clamps holding a modified torch head. Learned the stepper motors move the gantry using rack and pinions.

The prior flying gantry used two rails in parallel to stabilize rotation. From the model, v2 of the Torch the flying gantry will slide on one rail so some suitable bracking will need to happen.

Changes to consider in tool head design.

Changes to consider in tool head design.

Standards for oxy-acetylene systems: Threading is 1/4 NPT, LH threading for acetylene connections. Valves should be "grease-less" for prevention of combustible contaminants

Solenoid For Cutting Oxygen Flow: http://www.mcmaster.com/#standard-brass-solenoid-valves/=nmzf4c

Sat Jul 13, 2013

Design Sprint. Set Goals to work out details of acetylene/oxygen controls between tanks and torch head (Gas Delivery System). Review mechanics of slider gantries on table in solidworks for design considerations.