CO2 Laser: Difference between revisions

Jump to navigation

Jump to search

| Line 19: | Line 19: | ||

=Resources= | =Resources= | ||

*Extensive and comprehensive description of CO2 laser build - [http://www.repairfaq.org/sam/lasercc2.htm#cc2toc] | *Extensive and comprehensive description of CO2 laser build - [http://www.repairfaq.org/sam/lasercc2.htm#cc2toc], including poeple who have built them - [http://www.repairfaq.org/sam/lasercc2.htm#cc2hbl] | ||

*[http://www.laserk.com/newsletters/whiteCO.html Understanding CO2 Lasers paper] | *[http://www.laserk.com/newsletters/whiteCO.html Understanding CO2 Lasers paper] | ||

*Encyclopedia of laser physics - [http://www.rp-photonics.com/coherent_beam_combining.html] | *Encyclopedia of laser physics - [http://www.rp-photonics.com/coherent_beam_combining.html] | ||

Revision as of 21:39, 25 October 2009

Introduction

A low-cost laser cutter ($1-2k) can be made using laser engraver parts.

- The CO2 laser tube - $500 for 80 Watts

- Laser tube mount

- power supply

- focus lens - $65 at [1]

- lens mount

- reflection mirror

- mirror mount

Design Rationale

The enabling point of a practical, low-cost laser design is the ability to do significant cuts (1/8") by performing multiple passes over the cut pattern. If each cut does 10 thousandths of an inch in steel for an 80 watt laser - then 12 passes give you a 1/8" cut. This is sufficient, for example, to laser-cut a 20" Sawmill blade

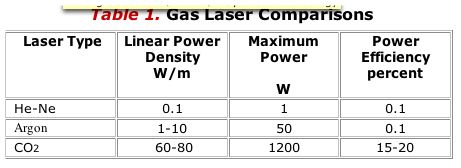

From [2]:

Resources

- Extensive and comprehensive description of CO2 laser build - [3], including poeple who have built them - [4]

- Understanding CO2 Lasers paper

- Encyclopedia of laser physics - [5]

- Excellent resources for homebrew lasers - http://planetstephanie.net/hi-tech-fun/lasers/

- Here's an Instructables laser cutter for thousands of dollars - [6]

- Not CO2, but still a homebrew laser engraver for $60, 1/4 watt - [7]

Suppliers

- American supplier of tubes and components - [8] - but pricey at $4k for 80 watts

- 100W RF laser from Synrad

Professional Consultants

- Laser Kinetics

- Sam's Laser

- Zach Radding, made a CO2 laser cutter featured in Instructables

Independents

- Number of contacts for people who have build high power lasers from scratch - [9]

- Sam Barros' PowerLabs