CO2 Laser

Main > Digital Fabrication > RepLab Tools > Laser Cutter

Power For Cutting Steel

Overview

See also Laser Cutter

A low-cost laser cutter ($1-2k) can be made using laser engraver parts.

- The CO2 laser tube - $500 for 80 Watts

- Laser tube mount

- power supply

- focus lens - $65 at [3]

- lens mount

- reflection mirror

- mirror mount

Design Rationale

The enabling point of a practical, low-cost laser design is the ability to do significant cuts (1/8") by performing multiple passes over the cut pattern. If each cut does 10 thousandths of an inch in steel for an 80 watt laser - then 12 passes give you a 1/8" cut. This is sufficient, for example, to laser-cut a 20" Sawmill blade

Bart Dring of BuildLog drew my attention to this: According to this, you need 106 watts per square inch (1.55kW/mm2) to cut metal. A 100W laser with a 280 micron diameter dot will cut metal. We would be looking for more precision than that anyway, perhaps 100 micron diameter, so 100W or less should suffice. Wavelength is more of an issue than power; metal acts like a mirror to a laser in the infrared spectrum.

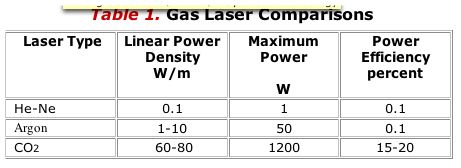

From [4]:

Resources

- Extensive and comprehensive description of CO2 laser build - [5], including poeple who have built them - [6]

- Understanding CO2 Lasers paper

- Encyclopedia of laser physics - [7]

- Excellent resources for homebrew lasers - http://planetstephanie.net/hi-tech-fun/lasers/

- Here's an Instructables laser cutter for thousands of dollars - [8]

- Not CO2, but still a homebrew laser engraver for $60, 1/4 watt - [9]

Suppliers

- American supplier of tubes and components - [10] - but pricey at $4k for 80 watts

- 100W RF laser from Synrad

Professional Consultants

- Laser Kinetics

- Sam's Laser

- Zach Radding, made a CO2 laser cutter featured in Instructables

Tubes

Independents

- Number of contacts for people who have build high power lasers from scratch - [16]

- Sam Barros' PowerLabs