Chris Reinhart Log: Difference between revisions

| Line 256: | Line 256: | ||

[[File:6 inch pipe.jpg|250px]][[File:6 inch 90 cut.jpg|350px]][[File:capping pipes.jpg|350px]] | [[File:6 inch pipe.jpg|250px]][[File:6 inch 90 cut.jpg|350px]][[File:capping pipes.jpg|350px]] | ||

'''Couldn't get the youtube video of this explanation to embed but here is the link: http://www.youtube.com/watch?v=v8qdbueT-Jg''' | |||

The end result... pipe stubs right where we want them to be! | The end result... pipe stubs right where we want them to be! | ||

Revision as of 23:53, 7 October 2013

Mon Oct 7, 2013

Have any of you guys seen this book?

http://www.amazon.com/Tiny-Homes-Shelter-Lloyd-Kahn/dp/0936070528

A book all about tiny (less than 500 sf) homes, by the well-known builder/author Lloyd Kahn (his first big hit was the highly influential book on DIY housing, Shelter).

Here's a little 2:00 minute video trailer for the book.

http://www.youtube.com/watch?v=u-2fsYypJoo

I mention this because I am going to contact him with the intent of getting the Microhouse in his upcoming book Tiny Homes 2. He and I have some mutual friends in the natural building world, so I think I'll be able to reach him without any difficulty.

-Chris

Sat Oct 5, 2013

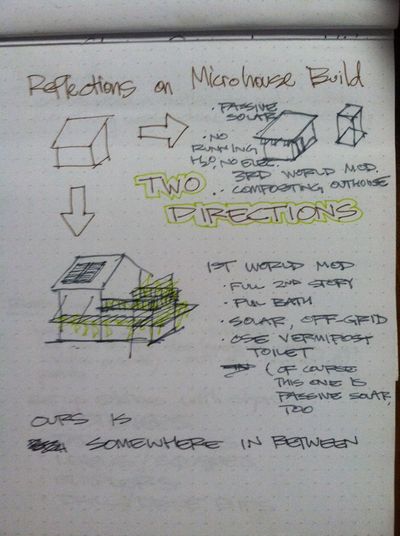

Next Microhouse Iterations Move in Two Directions

More details to come, but I think the next versions of the Microhouse should move in two different directions - one is the simple, very inexpensive, "third world" version. The other, a more refined, "first world" version. The Dwell magazine, version. Microhouse 1.0 is somewhere in between, but closer to the full-blown first world model.

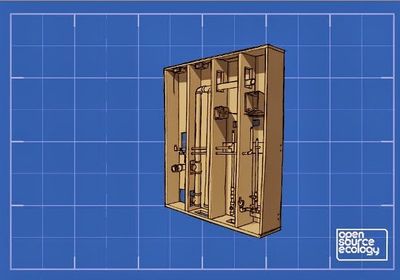

Infographics!!

I love the beginning of the Utility Module inforgraphic that Jean-Baptiste is working on. It looks fantastic!! Way to go, Jean!

I've got some various graphics in the works myself ;)

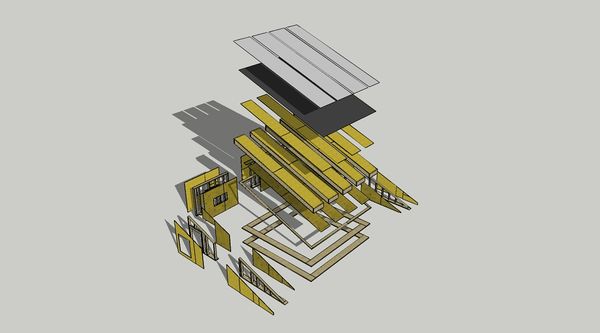

Obviously it's a mock-up. The graphic in the middle doesn't match the element logos for the modules, but I think you get the idea. A simple exploded diagram in the middle (on a white background, not gray), with leader lines extending to element logos for the different modules. Next to the modules, we place a photograph of the actual module. Short descriptions could be added, too. Need to finish element logos for all the modules.

Here's another mock-up - the idea here will be more like the periodic table. A simple arrangement of the element logos of the Microhouse.

And here's one more... this one is an aesthetically compelling photograph of the construction process showing which modules are used.

I think if we took well-composed (artsy, even) shots of construction, we could make a series of explanatory images showing how the modules come together during the construction process.

Fri Oct 4, 2013

Roof panels time lapse:

Infographic in progress:

Thu Oct 3, 2013

Yesterday's exterior plaster:

As I prepare to leave OSE headquarters and the Microhouse build I feel a mix of emotions.

I am elated at our progress and impressed with the quality and quantity of work that we have put out in the past 6 days. Building projects require the convergence of a multitude of inputs, and this one has gone more smoothly than many do. As a professional designer and builder, I am no stranger to solving problems on the fly and dealing with the unknown, but this project has been full-speed ahead from day 1, with no need to bring things to a halt and make a new game plan, the result of a robust design and planning process and many conversations between Marcin and I... and a very accurate and detailed sketchup model!

In addition to my happiness with how well the Microhouse has been coming along, I am sad that I cannot stay until the last screw has been driven. The house has taken its shape, but it is the detailing of home that really brings it to life, and I really wish that I could be here to make it sing. I have no doubt that I am leaving it in good hands, though, and that one of OSE's very talented DPVs will step up and carry this through.

Wed Morn, Oct 2, 2013

Plastering:

Walls Fully Stacked, Top Plate On

Yesterday, the crew succeeded in stacking the full height of the wall and attaching the top plate. The final form of the house is becoming apparent.

Also, made a run to Menard's last night to purchase some long metal tie-down straps, some "power-lags," another drill, and some 3" screws.

Tues Noon, Oct 1, 2013

Work on stacking up the walls is really coming along. 11 courses completed at lunch time. Just 5 to go!

Carpentry has been moving forward today, as well. First roof panel box is built up, and members are cut for the next 6. This evening, we will insulate them and put on the ceiling side.

Tues Morn, Oct 1, 2013

I got the first peek at the CEB floor this morning. The guys laid the last bricks in the dark last night, by the light of the film-maker's camera. I was anxious to see how it looked, so as soon as I woke up I ran up to the site before the day's work started and spent a few minutes alone with the Microhouse.

Mon Sep 30, 2013

Enormous Output of Work Today

We began the day with four courses of bricks stacked...

We started the day with laying the brick floor. We changed our plan about sand to use last minute, and local hauler Larry McPhee was a hero for bringing us a load of sand first thing. I woke the guy up this morning with my phone call, and at first he said he didn't think he could get us fit in. But when I told him where the delivery was going, he said, "The guys that build the tractors?" He showed up 90 minutes later with our sand. Thanks, Larry, for starting this great day off right.

Here is a great overview of the day's activities:

Sun Eve, Sep 29, 2013

Build Timelapse 1: Foundation liberation to brick pressing:

Pulverizer Timelapse:

Progress at brick laying and soil pulverizer closeup:

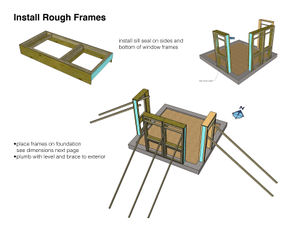

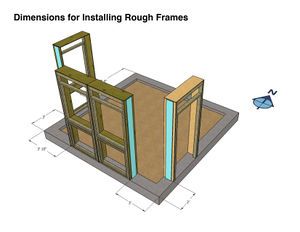

Window and Door Modules Placed

Before stacking the bricks, we installed the window and door frame modules, plumbed them, and braced them.

4 Courses of Bricks Stacked

We started stacking blocks late afternoon, and managed to get four courses stacked before nightfall!

The quick speed of laying up the brick is made possible by the tractor, the pulverizer/bucket, and the brick press.

Utility Module Complete

Today we finished the Microhouse Utility Module - the heart of the Microhouse and the most complex component to assemble.

File:Utility module complete.jpg

Door Loft Module Built

The final interior module was completed this morning.

The next carpentry steps will be to create the exterior walls for the upstairs level.

Sun Mid-Day, Sep 29, 2013

CEBs Made

Hot off the press!! Bricks getting made and stacked. The Microhouse is about to get vertical!

Sun Morn, Sep 29, 2013

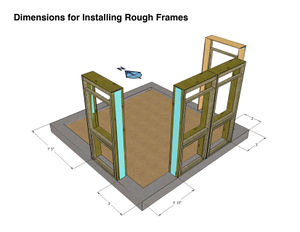

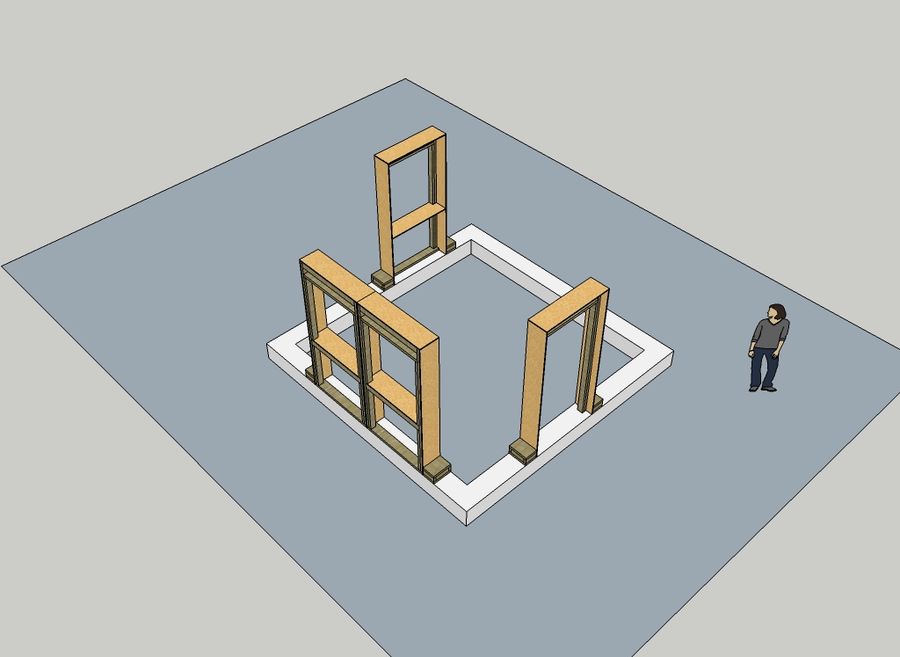

Rough Frames to be Erected on Foundation

Today we will place the rough window and door frames on the foundation.

Once the frames are in place, we will begin stacking the compressed earth bricks (CEBs)!!!

Sat Eve, Sep 28, 2013

Utility Module 92% Complete

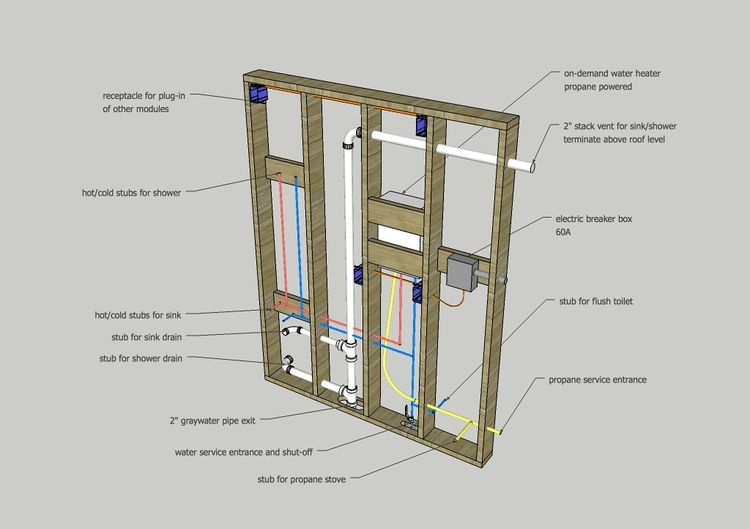

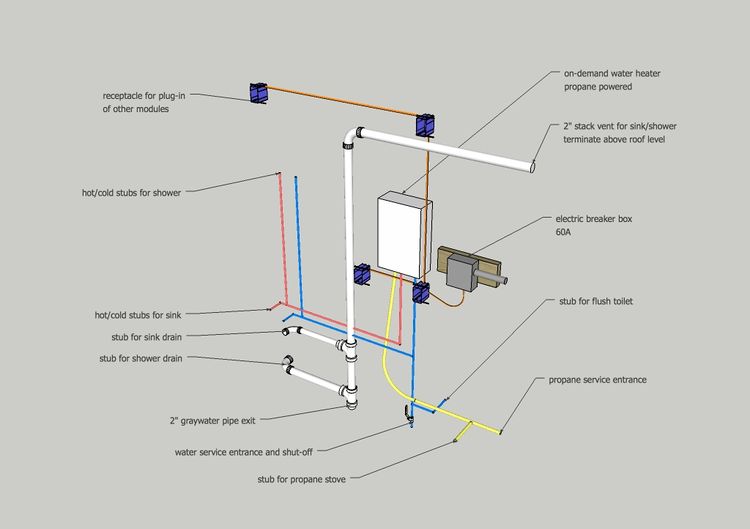

Work began today on the utility module - the heart of the Microhouse and the module with the greatest complexity. It contains all the plumbing and the majority of the electrical systems, and is design to "plug in" to the stubs roughed in on the building site.

The process was quite smooth, with a few hitches: not being able to find a small length of 1 1/2" pipe (it was plastic-wrapped to the underside of a long 2" pipe and three of us overlooked it at first), dead batteries on cameras and photo data-dumping necessitating some stoppages (what we're doing is only valuable if others can access the information). These were minor, though, and the end of the day found the utility module nearly complete!

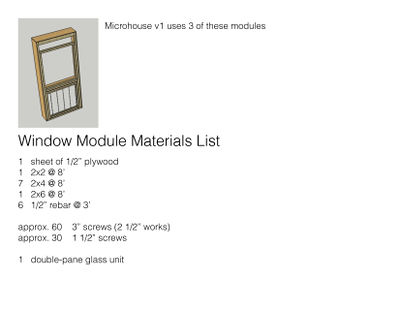

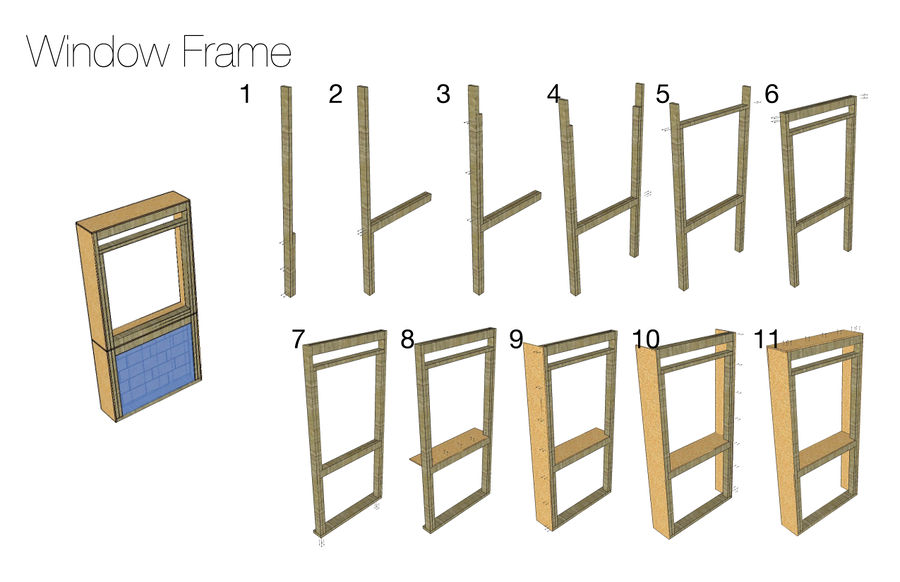

Window Frames Constructed

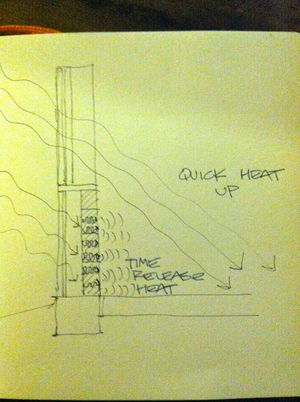

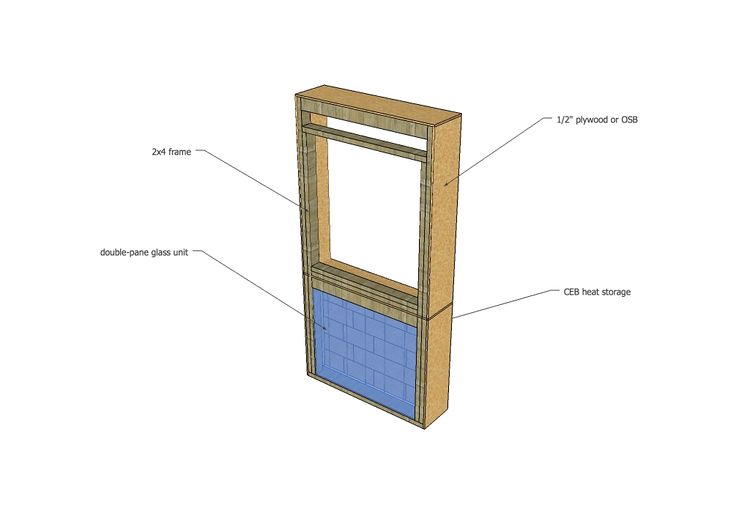

The window frame is more elegant than it actually appears. It is both a direct gain passive solar heater on the top, which quickly heats a space, and an indirect gain solar heater on the bottom, which heats a trombe wall which will store heat and release it into the space later.

The crew today finished three of these modules.

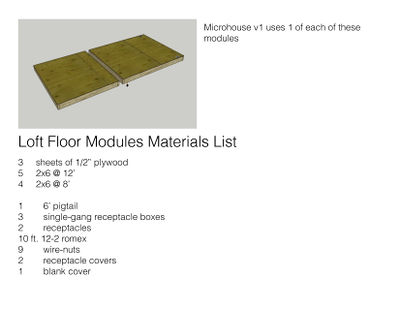

Loft Modules Constructed

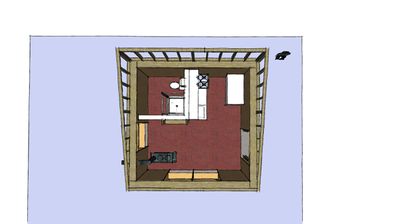

The Microhouse loft is composed of two modules. One is sized for a king-size bed, the other is intended as a small hang-out space or for storage. Both have minor electrical components of lights for the spaces below them, the kitchen light for the large module and bathroom light for the small. The small module also contains two outlets to bring power into the loft.

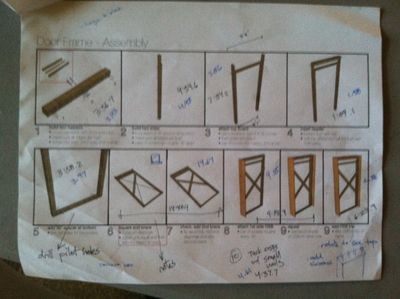

Door Frame Re-Work Done

On my first visit to Factor e Farm a month ago, I built a door frame with their intern Lucas. I called out the wrong dimensions for the opening, though. A couple weeks later, I had a moment where the first thing I thought of when I woke up in the morning was, "OMG, I think I messed up those dimensions!!" Sure enough, upon returning, I measured the frame and found the rough opening 2" too short in each direction. Today, the door module re-work was done. Thanks for redoing my work, Seth, so I could focus on the utility module!

Many Volunteers On-Hand

We were blessed with many hands today... Seth Jenkins helped run crews. John Motloch helped build and document the processes. Catherine Austin Fitts helped organize time tracking of the utility module. James Wise helped Lucas Warner, one of OSE's Dedicated Project Visitors (DPVs), and Marcin modify the tractor. Emmett McGregor, a DPV focusing on documentation, shot video, stills, and time-lapses of the day's work. Cody Harrison and Rob Beddingfield did a little of everything. Thomas and Noah Devick came mid-day and jumped right in. Rob Kirk, OSEs documenter, arrived mid-afternoon and started shooting along with Emmett. Many hands make for lighter work, and this group is a joy to work with!!

Sat Morn, Sep 28, 2013

Parts laid out for utility module

Getting materials laid out to be easily accessible when building is key to a successful workflow. Having a large table really helps! Materials are laid out in sections: DWV and supply plumbing, LP gas plumbing, and electrical.

Fri Eve, Sep 27, 2013

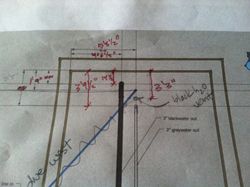

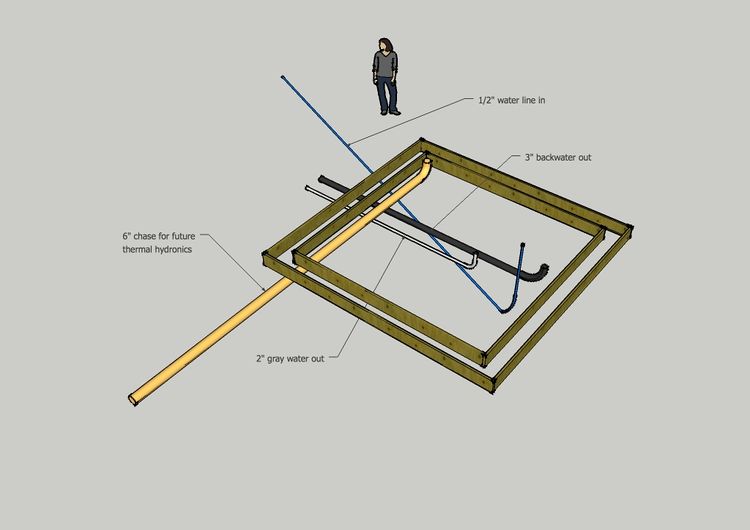

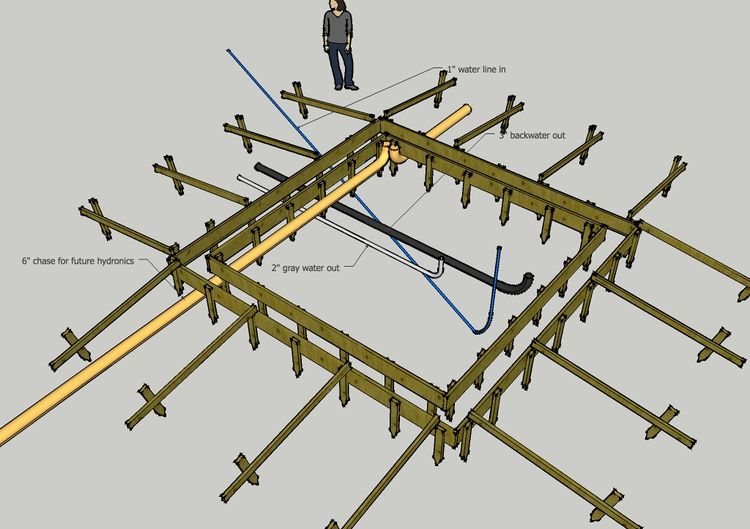

Drain Pipe and Chase Installed

Installed the drain pipes, the water inlet and the chase to enable thermal hydronics to connect to a future module.

In order to facilitate measuring the fall on drain pipes at 1/4" per 1', a small 1" jig is taped to the end of a 4' level.

Strings were attached to the foundation form boards; intersections show where pipes come through floor. Final dimensions shown on marked up sheet to make any adjustments needed to utility module.

3" blackwater pipe was installed first. Gravel was dug out, pipe was put in place and checked for proper fall. "Shit runs downhill," the old plumber's golden rule says, but it runs downhill best if it sloped at 1/4" per 1'. Too much fall, and liquids can outrun solids.

Always prime pipe before gluing to ensure a good bond. The vent pipe for the blackwater outlet (not shown in original drawing) penetrates the floor to come into the utility module. String intersections were used as guides and pieces were held in place to determine pipe lengths for cutting.

Once the 3" pipe was in place, a similar trench was dug out for the 2" line using the string as a guide. Here, the 2" and 3" lines are shown exiting the building. Both were kept low enough that the 6" line can go above them.

The last pipe to go in was the 6" chase that will eventually contain insulated PEX pipes to carry thermal energy to a future module. The 90 was too tall, so one of the bell-ends was cut off of it. Once the pipes were installed, the ends were capped with plastic bags and duct tape to avoid debris getting inside them before use.

Couldn't get the youtube video of this explanation to embed but here is the link: http://www.youtube.com/watch?v=v8qdbueT-Jg

The end result... pipe stubs right where we want them to be!

Fri Morn, Sep 27, 2013

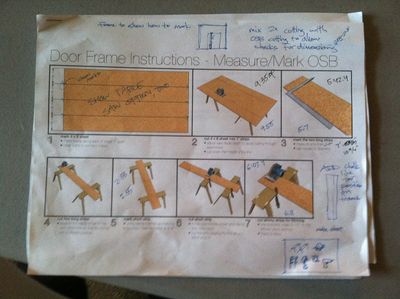

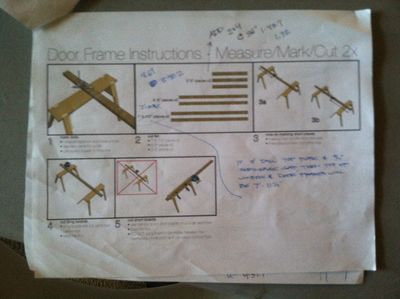

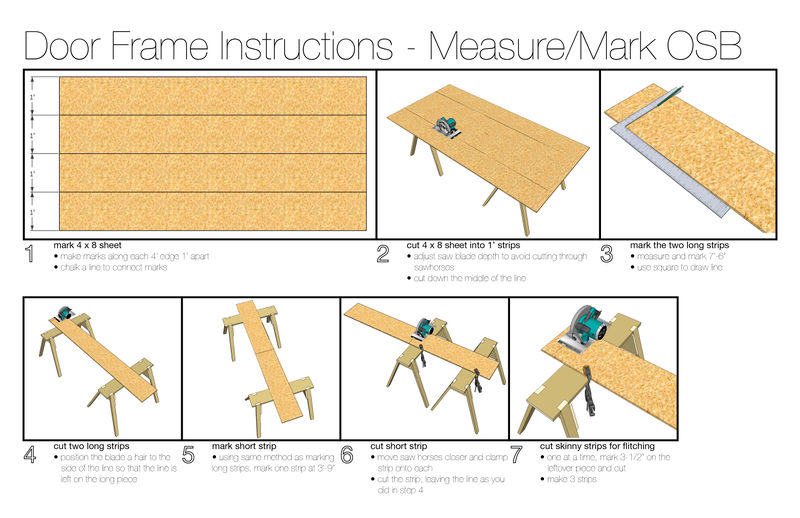

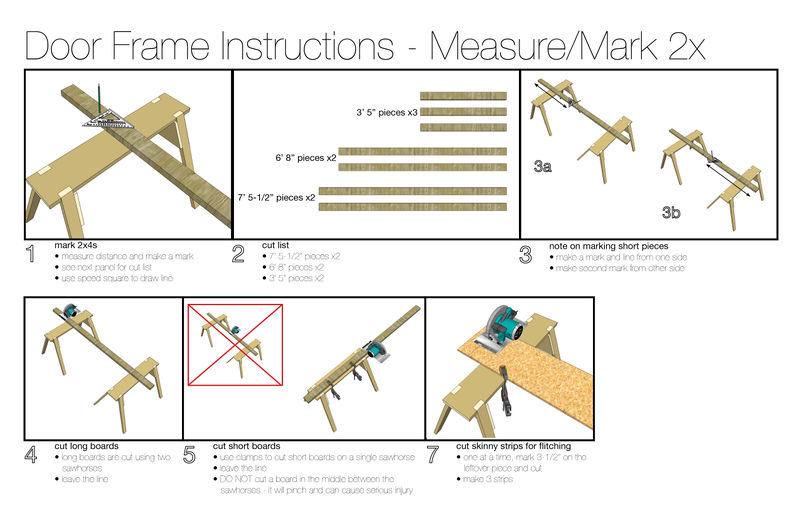

Arrived at Factor e Farm late last night. Finished printing instruction sheets this morning.

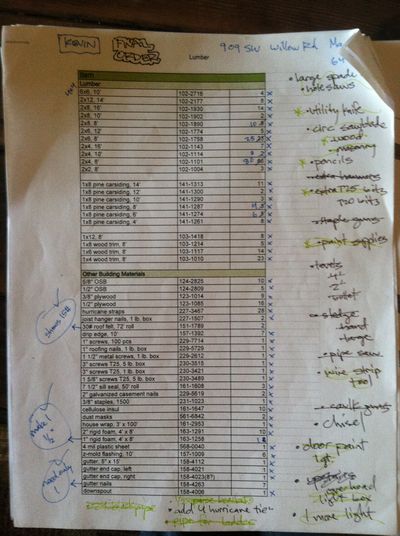

Spent much time on the phone with Menards on Wednesday evening making substitutions for items that were damaged/out of stock. Also made a final list of items to acquire before leaving

Thu Sep 26, 2013

Moved Brick Press 1 into place:

[[

OSE MicroHouse Update September 26 from E McG on Vimeo.

Wed Sep 25, 2013

Microhouse Final Bill of Materials

Microhouse Foundation pour - Time Lapse

LifeTrac 6 First Drive (basic walkthrough + soundtrack):

Tue Sep 24, 2013

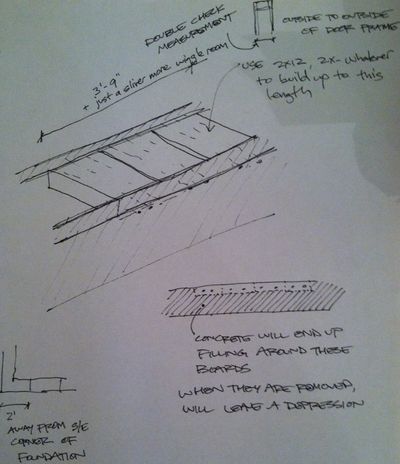

Door frame recess in concrete foundation detail sketch:

Mon Sep 23, 2013

Sun Sep 22, 2013

Chris Discussion

- Use Materials Requisition Form template - critical to track Ordered/Shipped/Tracking #/Received/Accepted chain - Material,_RFQ,_and_Work_Requisition

- Sensors - for hard data, $500

- Surface mount sensors - Open Source Temperature Sensors, illuminance, relative humidity, temperature reading, Open Source Infrared Camera from Public Lab

- 2 rebars per side - 16' from 20' section, 1 foot stub out

- Pay fuel costs only for travel

- Kitchen - 2 outlets -

- Extend loft over kitchen by 1.5 feet

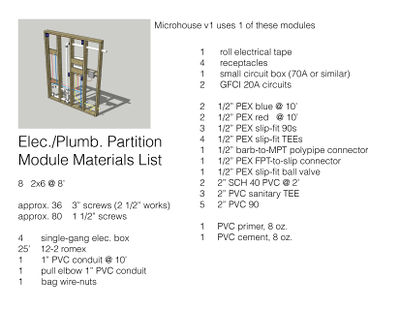

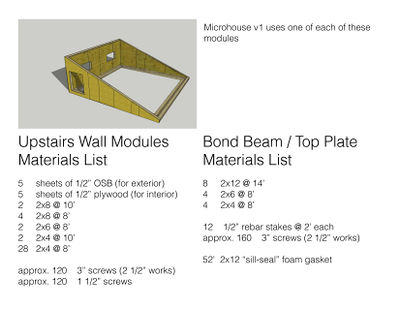

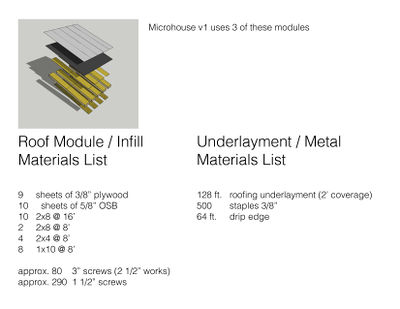

Materials Lists per Module

for final Microhouse v1 documentation, add sheets for materials already ordered (door frame, foundation)

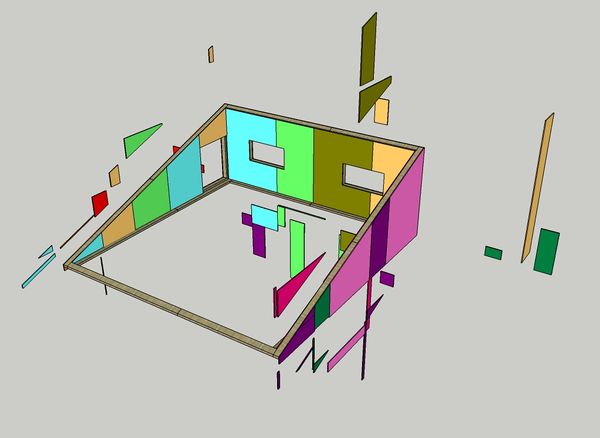

Plywood and OSB Counts Determined for Minimal Waste

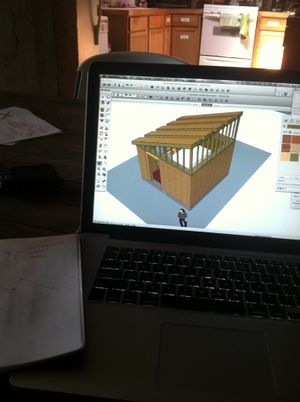

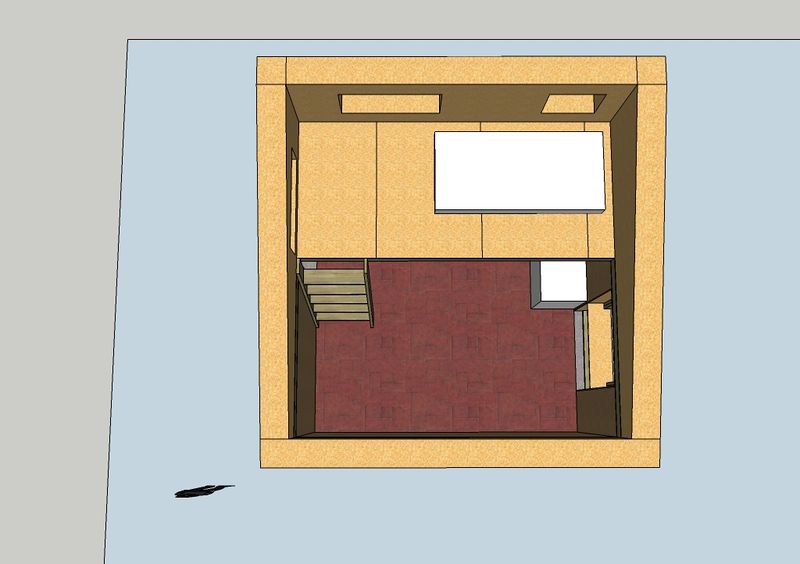

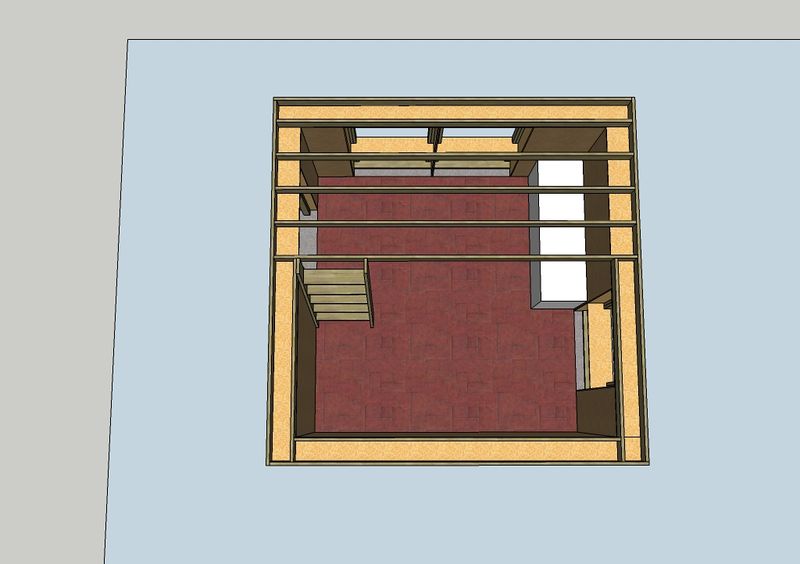

In order to ensure maximum efficiency with cutting sheet material, sketchup model was sheathed with different colored 4x8 sheets to track number of pieces needed. Totals for upstairs wall carpentry is 5 interior sheets (3/8" plywood in this case) and 5 exterior sheets (5/8" OSB).

Exploded Assembly Diagram for Final Animation In Process

Fri Sep 20, 2013

Meeting with Walter Grondzik, PE

Walter Grondzik is the author of Mechanical and Electrical Equipment for Buildings, the "bible" on building MEP systems and passive design, as well as The Green Studio Handbook, a reference for incorporating sustainability into schematic design. This afternoon, he graciously donated an hour and half of his time to the project. We talked about small design details regarding thermal performance, as well as ways of gathering some solid data on building performance.

Here's a video of Walter discussing the uses and rationale for adding sensors to a building - then we'll look at some details that were discussed.

Walter gets excited about building science. I wish I had captured on video our conversation about the different types of data collection he recommends. Here is the list:

1. Sensors, like the ones recommended in the video for ambient temperature, relative humidity, and illuminance.

Plug-ins to the sensors that are thermal probes.

2. Infrared (IR) Camera study

3. Blower door test.

Ball State has this equipment, but it needs to be looked into if it could be brought to the site at a later date during building operation.

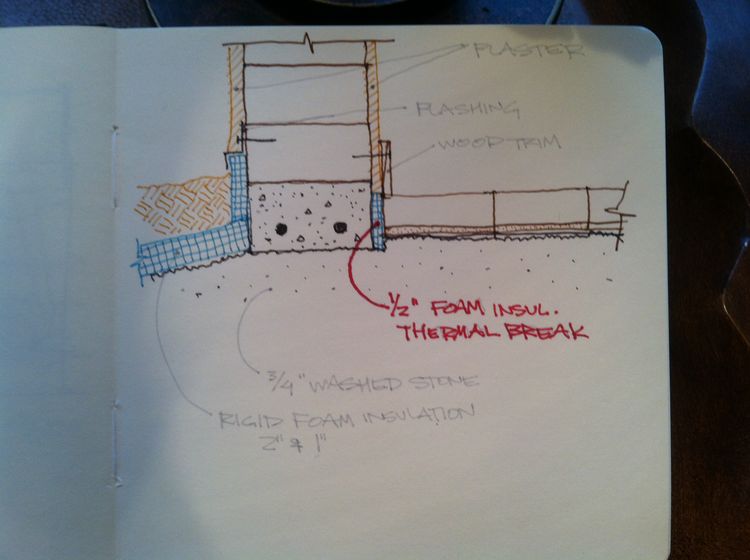

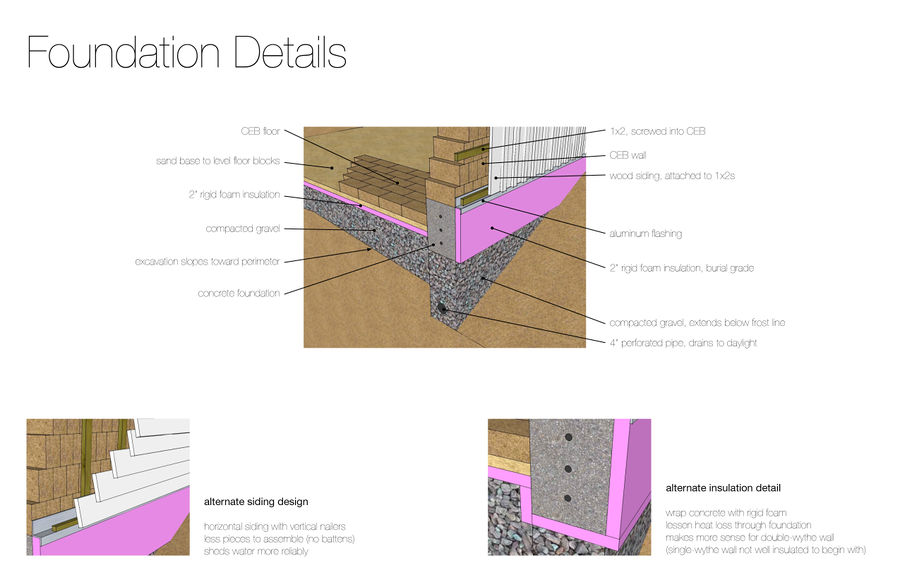

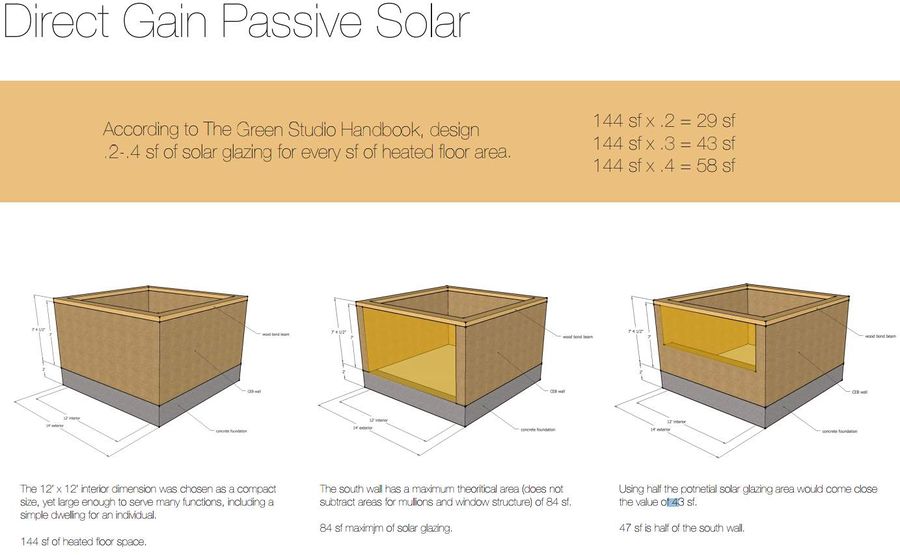

One item we discussed was getting the best performance from the direct solar gain heating system (heating of the CEB floor by sun shining through windows). Walter highly recommended putting in a thermal break between the floor and the foundation. Without this break, there heat will travel easily from the floor to the foundation. He suggested a 1" thick piece of foam, but he agreed that a 1/2" piece would be acceptable. Even at 1", the plaster and a trim board would cover it.

Walter reviewed the window design including the indirect gain solar heating system, and thought it was an idea that would work well. He also felt that the amount of glazing to floor area seemed appropriate.

This modular system - combining both direct and indirect gain systems - balances the quick warming felt with a direct gain system and the time-lag heat release experienced with an indirect gain system.

We spoke quite a bit about air sealing the building - a critical component when maximizes passive gains. He liked the idea of using a foam gasket (referred to often as "sill seal," in the field) between the window and door frames and the blocks stacking up next to them. Also, between the block wall and the top plate.

(More to come soon...)

Mon Sep 16, 2013

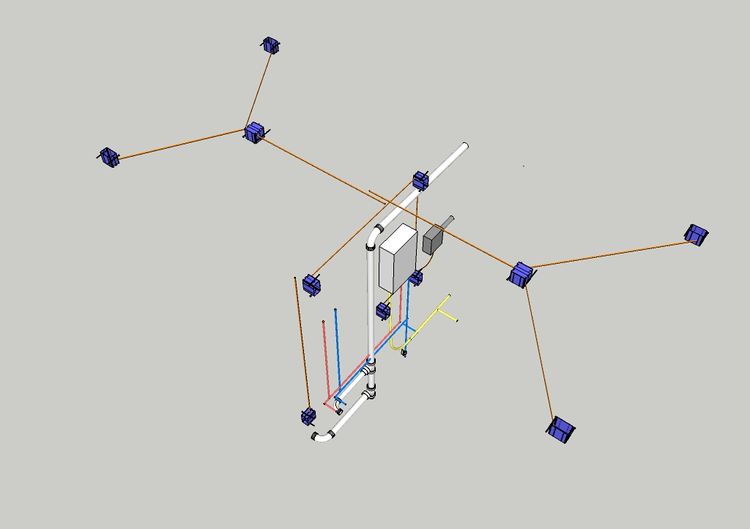

Utility Module Design

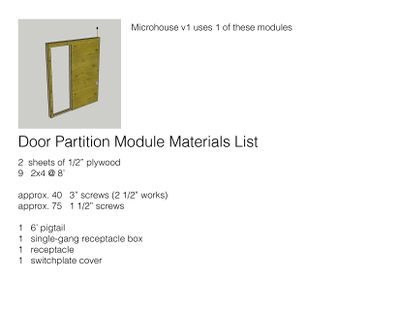

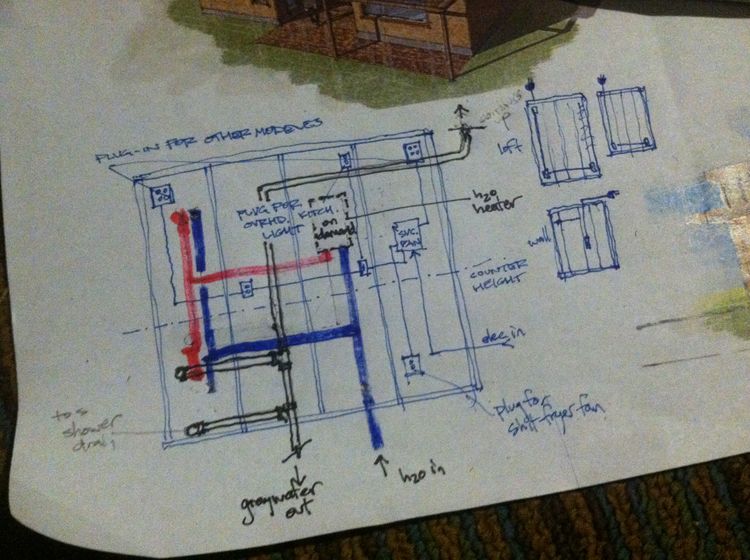

The utility module contains all the connections for the electrical and plumbing, and doubles as a partition wall separating the kitchen from the bathroom. This particular location allow all the plumbing connections to be inside a single wall.

Interior Partitions and Loft

Chris - remove power outlets above kitchen?

Extend section above kitchen about 1-2 feet to expand loft size / fit king-sized bed?

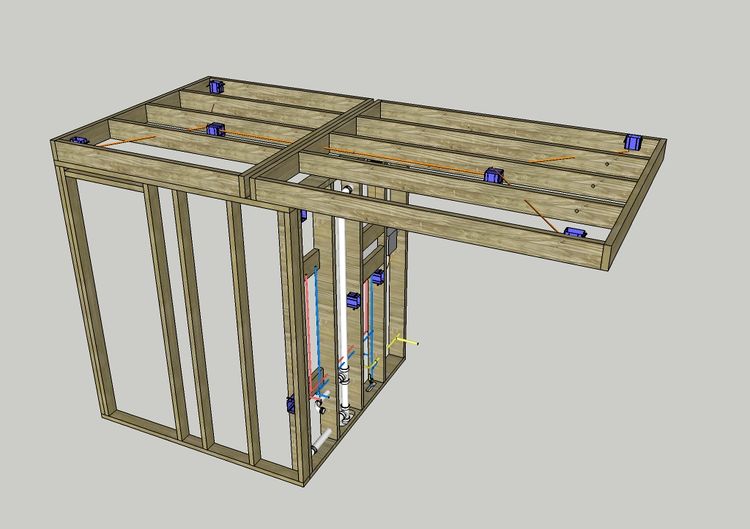

Interior partition walls and loft panels shown with sheathing/decking removed to view electrical and plumbing.

Sun Sep 15, 2013

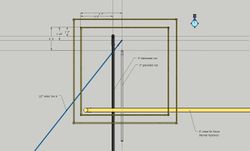

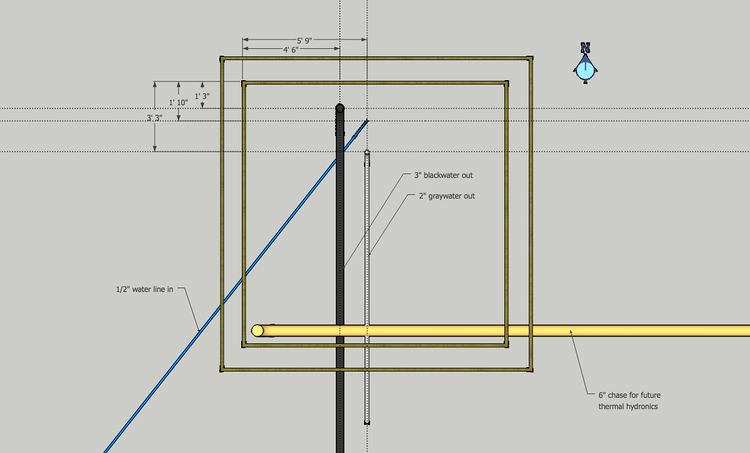

Precise dimensions for pipe layouts

Notes:

1. Measure and mark opposing interior form boards with dimensions listed.

1a. Measure from outside of inner form board (in other words, from what will be inside of concrete).

2. Put small nail into form top at location of mark - string between similar mark on opposing form board.

3. Run designated pipes under foundation formwork and make sure vertical pipe is directly under

proper intersecting strings.

4. 6" chase for future hydronics does not need to be at any slope.

5. 2" graywater and 3" blackwater lines MUST BE AT 1/4" slope per 1' of length.

This is required for proper drainage, otherwise liquids will outrun solids.

6. Pipe layout shows 6" chase running over 2" and 3" lines, however, it is typical to conserve as much

elevation as possible when exiting graywater pipes... best practice will be to run 2" and 3" pipe

out just below bottom of foundation formwork. 6" pipe will most likely run beneath level of 2" and 3" pipes.

7. Run pipes past foundation forms by roughly 5' and cap with cardboard/duct tape or old rag, etc.

Leave vertical pipes at a length of 1' taller than foundation forms. Cap this end, as well.

Staking the vertical pipe in place with rebar will prevent it from getting disturbed.

Pipe Elevations:

Sat Sep 14, 2013

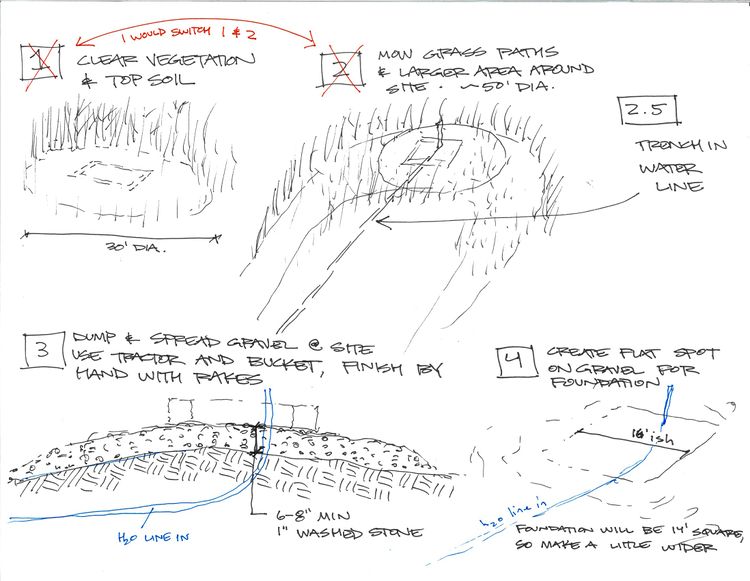

Microhouse site cleared:

Total Labor Hours: 1 hour mowing with string trimmer and metal blade; 1.5 hr leveling with tractor including removing former goat fence on west side.

Fri, Sept 13, 2013

Revised pipe and chase diagram - future thermal hydronics only going to east module because west module will be sharing a wall. Also, proposed North Utility Line.

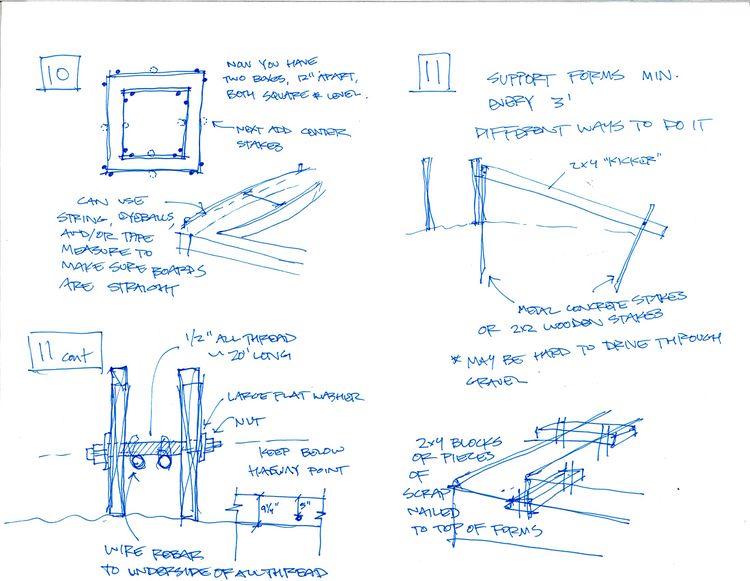

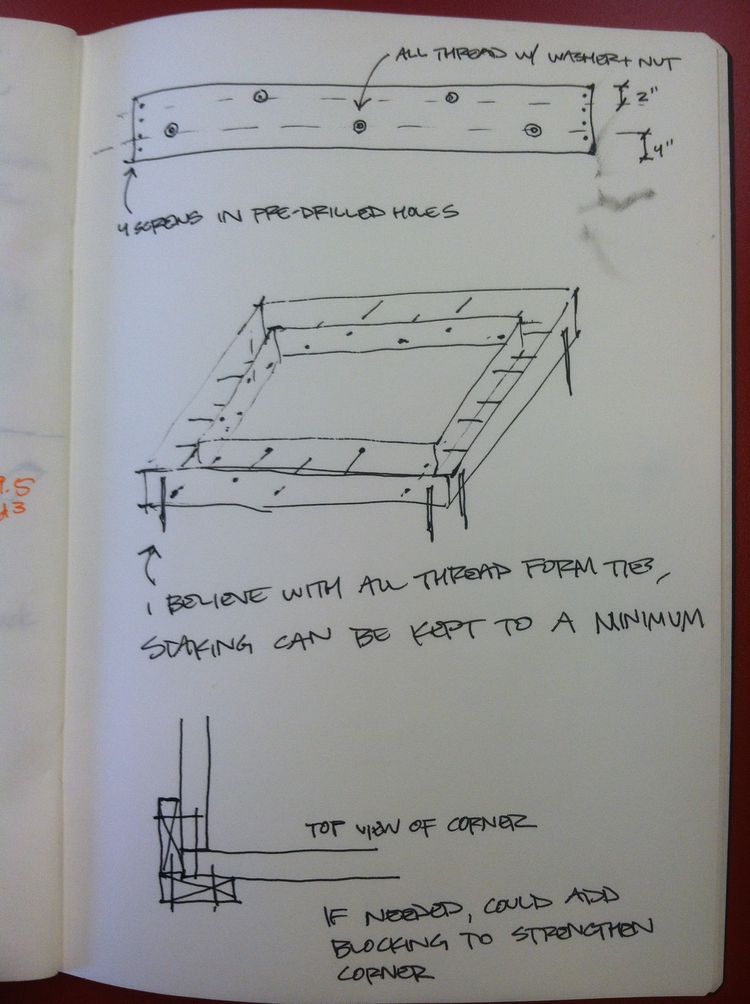

Updated bracing for concrete forms. Almost all bracing will occur with threaded rod, placed through holes drilled in the forms, and secured with a washer and a nut. Pattern for installation is shown in below photo. Staking can be kept to a minimum... 2 stakes per corner... just to keep forms square and in place.

Thurs, Sept 12, 2013

And, let's trench some water lines - see Trencher Prototype 1 Video

Open Source Trencher. from Open Source Ecology on Vimeo.

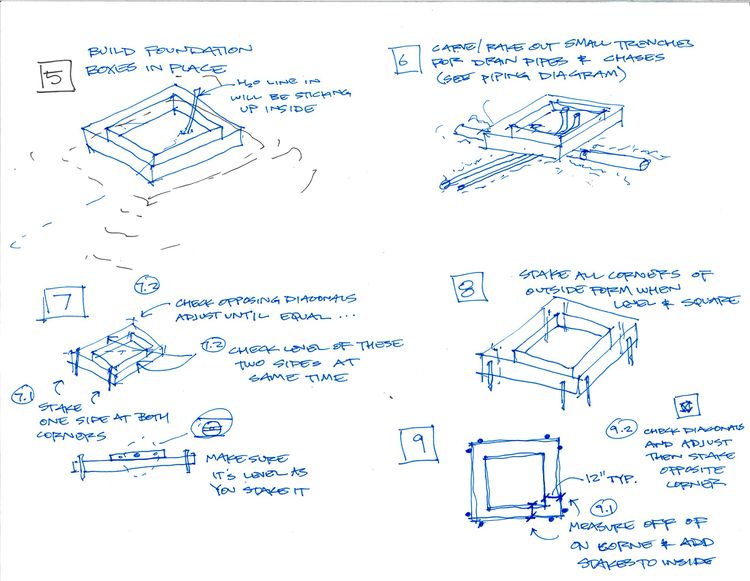

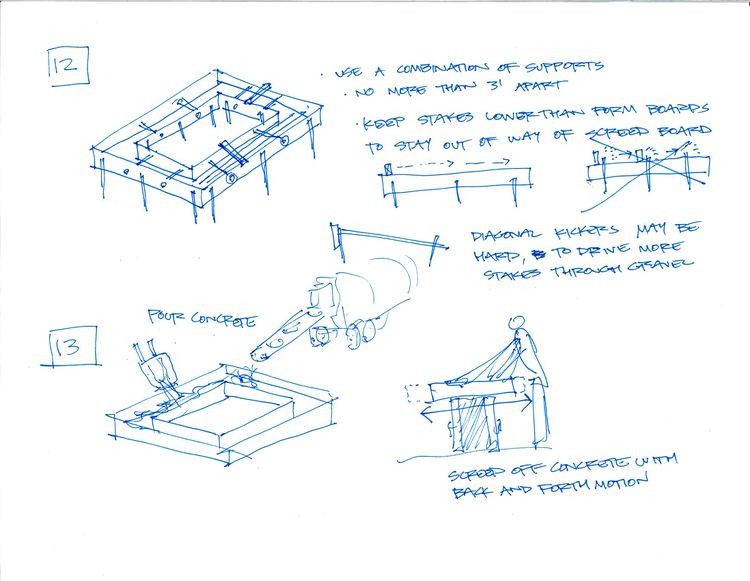

Foundation formwork with pipe and chase diagram

Instructions for foundation build...

For allthread, do 2 at corners and 2 in middel - 4 per side. For blowout, do 2 of them per side - 1/3 way each. Rebar ends up at bottom 1/3 of boundation. Allthread about 5 inches down from top.

Stub out 8-12" of rebar.

Do 4 pieces of allthred per side -

Foundation BOM

https://docs.google.com/spreadsheet/ccc?key=0ArpE5Y9PpJCXdC1KNG80OWRmdk85TlBQTVA3YWhRbEE#gid=5

Wed Sep 11, 2013

Planning spreadsheet -

Saturday, September 7, 2013

Specific Parts Sourced Plumbing and Electrical Modules

I spent 90 minutes today at the hardware store sourcing the components that we will use for the plumbing and electrical module. Here is a schematic drawing of the partition-wall-utilities-module:

Plumbing fittings for incoming water supply and for shower connection.

Plumbing fittings for incoming water supply and for shower connection.

Pex pipe and shut-offs for sink connection and flush toilet connection.

Pex pipe and shut-offs for sink connection and flush toilet connection.

Propane tube and connecting fittings.

Propane tube and connecting fittings.

Thursday, September 5, 2013

Flyer Created and Distributed in BSU CAP

This flyer is being placed in the hands of key professors and students in order to recruit talent for our first Microhouse build. I have no doubt that we will be able to fill a van with bright young designers to help us execute this project.

Speaking Engagement Booked

I have been given a time slot during Ball State College of Architecture and Planning's Alumni Symposium to present the Microhouse project. During my last presentation at the CAP student symposium, I spoke to a standing-room-only crowd of over 200 students and faculty. I expect this time will be no different. The timing is perfect, too, as it comes just a month after we will finish the build of Microhouse 1.

Profile in Book on Post-Petroleum Design

I have arranged a profile to be included in Dr. George Elvin's upcoming book on post-petroleum design that will feature the Microhouse. George and I became friends during my time as a student at Ball State, and he had been planning to include a profile of my other natural building work in his book. When we crossed paths this morning at a Muncie coffee shop, he was working on the book and reminded me that we need to schedule an interview. I suggested we focus the profile on the Microhouse and do the interview after I return from the build week. I'm very excited about the exposure this can bring to the project!

Tuesday, September 3, 2013

Current Microhouse Design and Overview of Build Week

During the last few days of September and the first week of October we will be constructing a prototype house, using prototype machines, and using a prototype process: swarming construction. Numerous volunteers, with various skill levels, will be refining a method of parallel processing to construct modular components of a house that can be quickly assembled to create a beautiful, durable, and sustainable dwelling for a couple: the Microhouse.

The build processes will proceed from an instruction manual, currently being designed, that will open the doors of creating one’s own shelter to almost anyone.

Every step of the process will be rigorously documented. As components are built, the instruction manual will be marked up with times for each step and notes for how both the process and the manual can be improved. At the end of each work day, debriefing sessions will capture lessons learned to refine the process. As the next day’s work proceeds, while some volunteers are building in the field, others will be revising the manual to reflect the lessons learned the day before. In this way, the learning will be captured as it happens. At the end of the build week, the product we will deliver is far more than a house, it is a process that makes building more accessible to everyone.

Sunday, September 1, 2013

Update on Prep Weekend for Microhouse Build

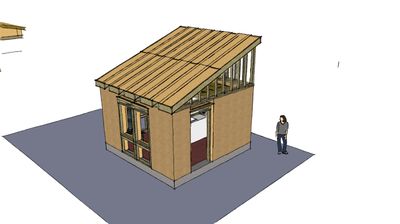

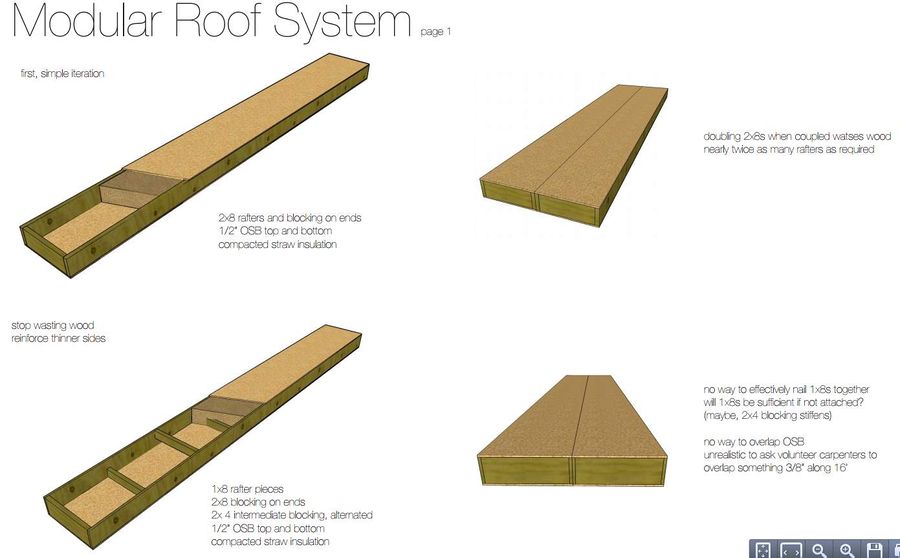

Over the past two days, Marcin and myself have refined numerous details of the Microhouse design. We have settled in on a roof panel module that we believe will be quick to assemble in the field by removing the tight tolerances necessary if panels mate tightly with one another. In this system, panels will be spaced apart roughly 14" or 15", eliminating the need for precision. 2' wide sheets of plywood will be screwed into place from the bottom to contain insulation, and once insulated, 2' wide sheets of OSB will be screwed onto the top.

The idea of the modular components for the mechanical and electrical system has evolved into the module being one of the partition walls in the building itself. This wall will contain the electrical and plumbing connections of the sink, shower, toilet, stove, and electrical receptacles. The partition wall will also support the loft panels. Loft panels will be pre-wired for electrical connections, and will plug in to receptacles on the electrical module-wall.

Layout for the interior of the Microhouse was determined.

An intern at OSE, Lucas, and I built the rough door frame from the instructions I had created. We timed each step of the process, and also marked up the instruction sheet for the second iteration. All pictures can be found on trovebox under the tag "microhouse."

Thurs Aug 22, 2013

Bill of Materials

Sample Construction

File:Detailed model first pass.skp

Discussion: Materials necssary for build of microhouse windows and roof panels. Saturday & Sunday - 4 people total needed. 3 teams of 2 - the best amount of people. Goal: how fast can inexperienced people build the house?

- Constructed Wetland - alternative to septic. Peter Bane, Brian Art Ludwig ($150/hr) - all the greywater books.

Next steps: BOM for sample framing and roof sections: Monday; build procedure - by wednesday.

Make sure all blades are in good shape:

- Table saw -

- Circular saw

- chop saw

- sawhorses

- screw guns - Chris has 1

- 1 gun per team

- Star head drive -

- 2 groups work

- Ask John for Recommendations -

Spoke with both Walter Grondzik ($50/hr for up to 10 hours) and Ryan Zaricki ($40/hr - 4-5 hours for hydronics) ... both are interested in contributing to the design of the project from an engineering perspective. Ryan had several ideas for moving heat with hydronics from one module to another. He has worked on several such projects. Walter is willing to consult on any MEP issues and to review the passive heating/cooling strategies used in the design.

Perspective shows earthen walls, door and window frames, bond beam, and roof panels. My feeling is that with the loft, there is too much wood framing... the design no longer celebrates the earth blocks like it should... too much carpentry involved.

Overhead of sleeping loft

Loft removed to see first floor. Kitchen counter could wrap wall. Stove can be placed in back corner by ladder or on opposite side. Window frame on west side of building could be converted to a door to access future addition.

Fri Aug 16, 2013

Foundation and Frames Set Up Before Build Day

This image begins to show the detail of what the foundation and framing set up will look like at the start of build day.

First Steps at Construction Diagrams

More detail is needed, but this sheet shows the steps in construction for a window frame. A cut sheet needs to be added. Also, more detail on the nailing is necessary, even though all nails are shown.

Wood Components

Shows detail of window and door frame, as well as a gringo block for attaching frames and a block for service entrance of data and electricity.

Wed Aug 14, 2013

Foundation Details

Drawing of foundation details without dimensions - final dimensions to be determined.

Wed Aug 7, 2013

Concept drawing thoughts

reverse shed roof to allow for easier mounting of solar panels

look at option of upper windows for ventilation

add landscaping rain barrell viney plants

Mechanical and plumbing modules - Mechanical and Electrical Equipment for Buildings -

File:Direct Solar Gain.pdf

Passive Solar - Direct Gain

Chosen as the best passive heating strategy because of the building size. Future designs should explore indirect gain systems, as well. The page of calculations is a starting point for determining apertures.

Notes, in addition to what is on drawings pages (should be added to drawing pages) -Aperatures must be within 15 degrees of true south (north, in southern hemisphere) for the building to receive 90% of optimal winter heat gains (Green Studio Handbook 107)

also note that the Green Studio Handbook states… “The first, and most important step in the design of a passive solar heating system is to minimize the rate of heat loss through non-south-facing envelope components (including infiltration losses).” (109)

The single-wythe version of the CEB building will have the potential for large heat losses. Although thermal mass can help, uninsulated earth walls, when they get cold, they take some time to warm up. My experience in the earthen section of my home is that if I am at home throughout the day or at least in the mornings and the evenings, the home will stay cosy. If gone for a couple days in the winter, it takes a half a day or better to make the home feel good again.

The double-whythe section offers greater potential to use the solar gain by being better insulated.

Roof Panels

Despite an enormous amount of information on prefabrication on the internet and at the library, it is clear that we are not working in the mainstream here. Every prefabbed roof panel I could find was a single, lifted-into-place-with-a-crane-type. We want something that four people can comfortably lift to a height of 8+ ft. Ideally, we want this technology replicable on two-story and greater buildings.

My explorations were based on the idea that four people could move a panel with a weight of about 200 pounds. The weight for the first iteration of the roof module is about 180 pounds without straw infill. (add weight calculations to drawings – also, final documents should include both English and metric units).

I think that the roof panel design can be improved as the details are explored. I think encasing the open side of the panel so that the straw cannot impede the panels coupling together would be slick. Something like luan plywood or masonite. Ideally, this thin piece is caulked into place, and the panels are caulked together when assembled.

The roof will have more linear feet of potential crack than any other component (assuming that the stucco is impermeable to moving air).

I would like to add to the schedule of events for the Labor Day visit that we build a full-scale test of a roof panel and track the process closely. It also makes sense to prebuild a jig for assembling the roof panels.

Construction Process

Numbers listed in contract add up to 28.

I think the mechanical unit might be best conceived as two units – one for plumbing, one for electrical – the idea of having critical connections of water and electricity and gas all next to each other is uncomfortable, indeed. This would break the team for the mechanical unit into two teams of 2.

What type of stucco is being used? Depending on the answer to that question, I think the stucco team of 4 could be smaller earlier in the day. We could go with 10 for bricks – 3 sliding and 5 laying. This could be one way of re-arranging if we are trying or needing to stay at exactly two dozen volunteers. If not, I think your numbers for adding up to 28 are comfortable.

House Layout

The two modules, separated by a courtyard, will create a wonderful outdoor space to be used for eating (cooking even, if desired), for relaxing, and for entertaining. However, two buildings separated require two separate MEP systems. Is it possible to arrange the building program so that functions are separated that have similar MEP needs? Could one space function without plumbing and gas?

One module with electricity, data, plumbing and gas:

- Kitchen

- Shower

- Toilet

- Dining

One module with electricity and data only:

- Bedroom (sleeping loft?)

- Living space

- Work Space

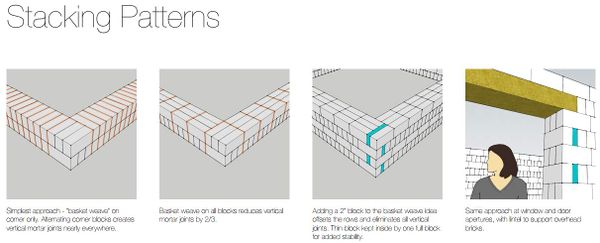

Brick Stacking Patterns

This makes the most sense to me as a couple trying to build a microhouse. Why plumb, and water a space that I just want to sleep in? Separate functional spaces. Esp in hot climates an outdoor kitchen is great, but that provides shade.

This makes the most sense to me as a couple trying to build a microhouse. Why plumb, and water a space that I just want to sleep in? Separate functional spaces. Esp in hot climates an outdoor kitchen is great, but that provides shade.

Time Log

Thu Aug 1, 2013

- See Microhouse Build Planning and Chris Reinhart Contract

- Initial conversation on design with Marcin

- Planning first cut of design on Wed, Aug 7

- Water Glass for stone sealing or - [1]

- Stove - [[2]]

- Factor e Farm site plan - Factor e Farm Site Plan

- Beginning of brick courses - Brick Stacking Patterns

- Soil map - [3]

Sketchup File - File:Microhousev1.skp

Image of above: File:Mhv1.jpg

Links

- Overall Time log - [4]