Steam Engine Specifications: Difference between revisions

Jump to navigation

Jump to search

(Added category.) |

No edit summary |

||

| Line 1: | Line 1: | ||

{{Category=Steam Engine}} | {{Category=Steam Engine}} | ||

=Summary= | |||

*Deliverable: a one cylinder prototype module with scalability, to constitute a single stage of a stageable system (compound or 3 stage) which uses the same module that is scaled to make other stages | *Deliverable: a one cylinder prototype module with scalability, to constitute a single stage of a stageable system (compound or 3 stage) which uses the same module that is scaled to make other stages | ||

| Line 8: | Line 8: | ||

*Applications to stationary, mobile, and solar power | *Applications to stationary, mobile, and solar power | ||

=Cost-Related Features= | |||

*Lowest materials cost for a given performance | *Lowest materials cost for a given performance | ||

| Line 18: | Line 18: | ||

*''Materials'' cost of $50/hp | *''Materials'' cost of $50/hp | ||

=Materials Calculations= | |||

*20 pounds of weigh per horsepower | *20 pounds of weigh per horsepower | ||

=Flexibility and Performance= | |||

*Scalable in power output from 1 - 100 hp by scaling or adding modules | *Scalable in power output from 1 - 100 hp by scaling or adding modules | ||

| Line 30: | Line 30: | ||

**Multiple cylinder, in-line configuration is possible by bolting several cylinders together | **Multiple cylinder, in-line configuration is possible by bolting several cylinders together | ||

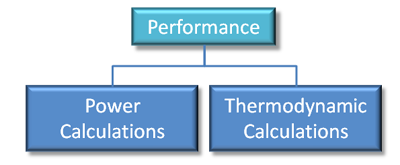

[[File:Performance-Chart.png]] | |||

=Lifecycle= | |||

*Long lifetime under continuous use (50 years) | *Long lifetime under continuous use (50 years) | ||

=Ecology= | |||

*Compatible with stationary, solar, and mobile power applications | *Compatible with stationary, solar, and mobile power applications | ||

| Line 41: | Line 43: | ||

**CHP with space heating | **CHP with space heating | ||

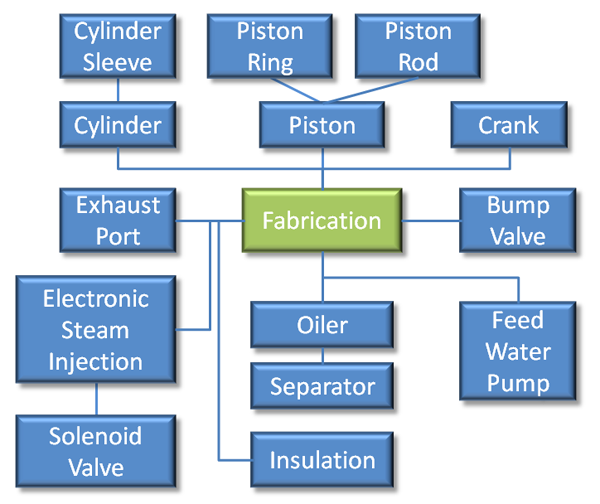

'''Fabrication:''' | =Fabrication= | ||

[[File:Fab-Chart.png]] | |||

'''Prototype 1 Fabrication Elements: | |||

* Cylinder | |||

** Cylinder support assembly | |||

** Cylinder sleeve | |||

* Piston | |||

* Piston Rod | |||

* Bump Valve | |||

** Ball | |||

** Spring | |||

** Bump Rod | |||

** Case | |||

** Steam Connection ?? | |||

* Oil sprayer | |||

* Crankshaft | |||

** Shaft pieces (2) | |||

** Offset plates (2) | |||

** Crank piece (1) | |||

** Couplers (2) | |||

** Screws | |||

** Crankshaft support assembly | |||

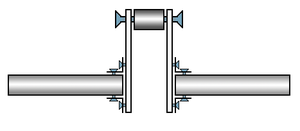

'''Crankshaft:''' | |||

* no welding in this design. | |||

* does require tapping holes for machine screws. | |||

* needs counterbalance to not vibrate. | |||

[[Image:Crankshaft.png|thumb]] | |||

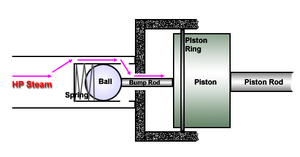

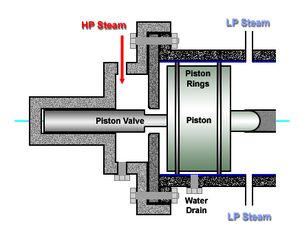

'''Valves:''' | |||

* Bump Valve - forgiving but springs may be a problem. | |||

* Piston Valve - requires precision but solves spring problem. | |||

[[Image:Bump-Valve.png|thumb]] | |||

[[Image:Piston-Valve.png|thumb]] | |||

'''Techniques and Stock:''' | |||

*Casting used for body | *Casting used for body | ||

Revision as of 18:58, 5 May 2011

Main > Energy > Steam Engine

Summary

- Deliverable: a one cylinder prototype module with scalability, to constitute a single stage of a stageable system (compound or 3 stage) which uses the same module that is scaled to make other stages

- System consists of cyliner, crank arm, mechanical valve, automatically adjusted cutoff ratio, and constitutes a Steam Engine Construction Set

- Cutoff ratio controlled by closed loop electronic feedback with some type of linear actuator

- Applications to stationary, mobile, and solar power

Cost-Related Features

- Lowest materials cost for a given performance

- Simplest to fabricate, therefore lowest fabrication cost

- Advanced techniques of fabrication utilized only when necessary to achieve cost

- Fabrication tooling preferably simple, but secondary to fabrication cost

- Uses commonly available parts

- Replicable

- Materials cost of $50/hp

Materials Calculations

- 20 pounds of weigh per horsepower

Flexibility and Performance

- Scalable in power output from 1 - 100 hp by scaling or adding modules

- Power density of 1 hp/10 lb

- Pressure up to 500 psi

- Scalable cylinder dimensions, uncoupled staging, and tandem operation allows scaling of power and eficiency from 1-100 hp and up to 25% efficiency

- Multiple cylinder, in-line configuration is possible by bolting several cylinders together

Lifecycle

- Long lifetime under continuous use (50 years)

Ecology

- Compatible with stationary, solar, and mobile power applications

- LifeTrac power source

- Solar Power Generator heat engine

- CHP with space heating

Fabrication

Prototype 1 Fabrication Elements:

- Cylinder

- Cylinder support assembly

- Cylinder sleeve

- Piston

- Piston Rod

- Bump Valve

- Ball

- Spring

- Bump Rod

- Case

- Steam Connection ??

- Oil sprayer

- Crankshaft

- Shaft pieces (2)

- Offset plates (2)

- Crank piece (1)

- Couplers (2)

- Screws

- Crankshaft support assembly

Crankshaft:

- no welding in this design.

- does require tapping holes for machine screws.

- needs counterbalance to not vibrate.

Valves:

- Bump Valve - forgiving but springs may be a problem.

- Piston Valve - requires precision but solves spring problem.

Techniques and Stock:

- Casting used for body

- Stock parts wherever feasible

- Lathing for bore

Other:

- Safe in case of failure