Solar Power Generator Distillation Transcript

Transcript from Weblog

Today’s episode is on the Solar Power Generator (formerly called the Solar Turbine) - a solar thermal concentrator (STC) electric system. Conceptually, this system is quite simple. Heat from the sun is concentrated by reflecting mirrors onto a collector. The heat boils water in the collector tube, and the resulting steam is used to run a steam engine. 70% of the energy in the United States is generated by steam power in large power plants [1], which use fuel to boil water. We aim to use the sun in our case.

We are presenting this video to explain how the Solar Power Generator could be feasible on a small scale – and how we plan to do it. We’ll be hosting the this year to do this..

Everyone loves solar energy. Did you know that the solar power coming to the Earth is 8000 times more than the total energy use on the entire Earth? This means that there is plenty of solar energy, but the trick is to capture it into a useful form. That’s where solar concentrators are used. In fact, you can see videos on YouTube that show solar concentrators melting right through steel.

So why doesn’t everybody have a solar collector to power their house, and save an average of $1000 per year in bills, if you are talking about the United States?

The reason is that harnessing solar power is too expensive by present standards, though this is now changing. Solar thermal concentrator (STC) power is actually economically feasible today, in sunny areas. There are large, megawatt scale utility plants in the desert regions of the USA, such as the company Ausra.

Indeed, Ausra has claimed that with its collectors combined with 16-hour thermal storage, it could provide all the power for the [entire USA http://montaraventures.com/energy/2008/03/10/ausras-bold-claim/]. See the paper on Ausra's first test results - [2].

At the same time – there is no small-scale version of Ausra for individual homes. We are proposing an open source system that is feasible on this small scale.

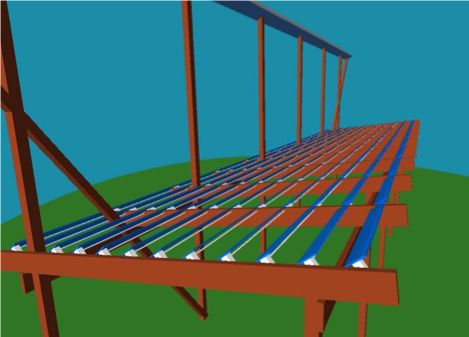

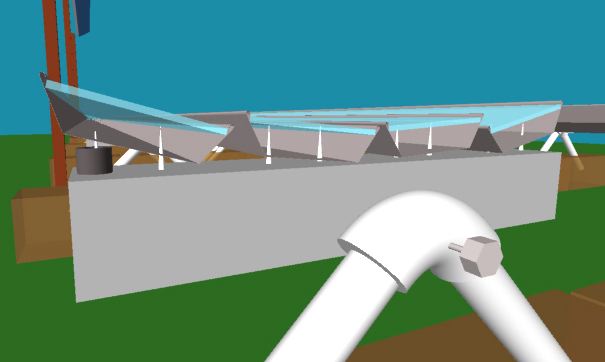

We are interested in the Linear Fresenel Reflector (LFR) configuration – just like Ausra. We are talking of a set of 60 foot long slats, 6 inches wide – 16 of these – pointed on a collector tube for 16x concentration. The collector tube has a parabolic shroud that adds another 3x concentration – for about 48x concentration total. This array runs E-W for 60 feet, and is 15 feet wide in the N-S direction .

Each slat is controlled by an individual tracking motor. Electronics today make this cheap and effective. Plus, we’ll be using a steam engine. We’ll be capturing 48 kW of solar intercept, and on paper, we’re getting an overall efficiency of 47% for the collectors after detailed calculations, and 15% for the steam engine to get 7 percent overall efficiency for about 3 kW of electric power.

We are proposing a materials cost of $1-1.3/watt – with the former being without and the latter with off-grid battery backup.

We are aware of the immediate critique of this proposition We know that this cost figure is highly suspect to just about any critic with basic knowledge of solar concentrator power.

Agreed. So here are the points that need to be achieved for us to deliver the predicted cost.

Development Points

Point 1

First, we need to develop the single reflector slat mirror mounting and rotation control – at $7 material cost per 10 foot slat, or $17 if we include the mirrors at $2/sq ft, see our work. The strategy for this is to have a small motor on each slat, plus feedback electronics that sense the location of reflected light on the collector tube, and make ongoing adjustments for focusing light on the collector. While a linkage of multiple slats controlled by one motor sounds easier to do, it appears from our research that it is insufficient to align all of the reflectors at one time – and why bother if cheap electronics allow you to do individual control? The sure bet is individually controlled reflectors, with feedback for adjustment – not a preprogrammed solar tracking path. Note also that ganged reflectors like this:

require a stronger mounting structure, and are reportedly proprietary.

Furthermore, we experimented with parabolic reflectors in the first convergence, but for reasons of simplicity, we decided to go with individual slats. Until disproven, this is the simplest, most replicable choice - with minimal structural requirements.

Point 2

The second point of development is the collector tube assembly. We need an explicit design that addresses radiation, conduction, and heat loss from the collector tube. Basically, we need to have the assembly trap all the heat it can in the collector tube.

Point 3

The third part is collector tube feedwater. For the solar application, valving is a solution because is requires much less energy to operate than a feedwater pump – on the order of watts instead of hundreds of watts. This means that we’ll have hundreds of watts more usable power. Another company which is currently developing a solar thermal generator is also using valving for exactly the same reason, and indeed claims it to be its key to success - [3]

Point 4

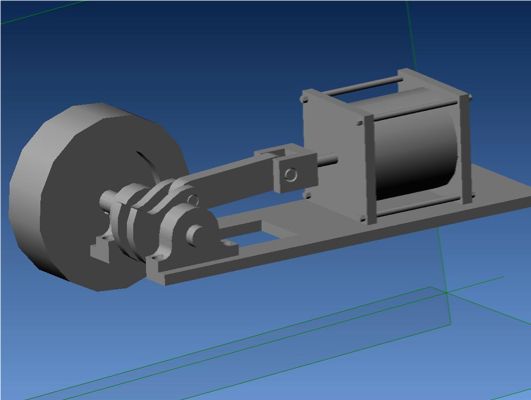

The 4th part is the steam engine. These are available at $1370 for a 5 hp engine suitable for our purposes. Our goal is to produce these from scrap metal by casting and machining with digital fabrication assist, for an engine that costs $150 in materials. This is very ambitious, but given that most of the scrap steel required for this costs only $10, we think this will be feasible – with digital fabrication as in Factor e Live Distillation Part 6.

Point 5

The fifth development point is electronic control for the steam engine. This may be the holy grail of high-performance steam power for solar applications. The above steam engine is simplified with a major modern advancement – electronically-controlled steam injection. Arduino-based electronics will control a valve that controls the steam feed to optimize steam usage. This is not only a simplification, but also an efficiency boost. From our search to date, we found no off-shelf valves suitable for steam engines. This means we have to develop an open source steam valve for this particular purpose.

Point 6

The sixth improvement that we have to do is a dedicated electrical generator that can be coupled directly to the steam engine for electrical production. We need a dedicated generator optimized for our application – so we need to opensource this as well, at $150 in materials cost.

Point 7

The seventh development point is steam cycle integration – from water injection to the collector tube, to the engine steam injection, to cooling and heat recovery. This completes the project.

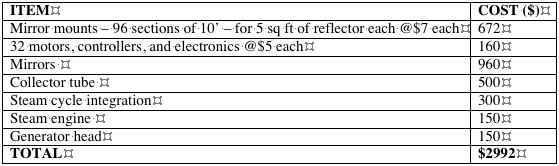

The above budget for material cost is $2992:

In summary, we have shown detailed calculations of 47% for collector efficiency , and the steam engine performance is expected to be 16% based on empirical data. All together, this comes out to a 7% system efficiency, a modest but sufficient result.

Second Solar Convergence at Factor e Farm - August, 2009

The plan is, therefore, to get the team together for the 2nd Solar Convergence at Factor e Farm, Aug. 1-31, 2009 – for the entire month of august until the system is complete. We’ll do the reflectors and collector tube, and we will have the steam engine by then – for system integration. We are calling this convergence Open Solar 2.

We are assembling teams for each of the seven development areas above, plus a marketing team..

The basic goal at present is to demonstrate 3 kW from the system - $3k, or about $1/watt predictions. You will be able to replicate this from detailed documentation, and we can provide key components.

We also aim to provide complete kits to you – for about $4500 – or $1.5/watt. We aim to have the steam engine for $250 as a turnkey product – and we’ll see where we get with that.

For now, tell your friends about Open Solar 2, and join one of the development teams before then. This is only a brief intro to the project – read more at the Category Open Solar 2 and Solar Turbine- on the wiki.

Working Questions

Working questions that are still unanswered to full satisfaction are found at the. We call these Red Pages because they a stop to progress. As answers become available, the questions are still kept at the respective Red Pages, but are placed at the bottom of these pages with answers attached.

Collaborators

These are all the people working on the project. We are compiling a list, together with listed areas of expertise, so research questions can be answered by consulting with particular collaborators. We are keeping track of all collaborators under the Collaborators category, and keeping track of Collaborators for this particular project at the.