Dairy Milker/Research Development: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 31: | Line 31: | ||

*See page 8 of link "Milking and Milk Quality" for a full diagram | *See page 8 of link "Milking and Milk Quality" for a full diagram | ||

*'''Simplified Dairy Milker''' | |||

[[File:dairymilkeroverview.jpg]] | |||

===Milking Unit=== | ===Milking Unit=== | ||

Revision as of 20:30, 7 September 2011

| Dairy Milker | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Research

Wanted: Brief description about the highest version of the GVCSTool

Theory

Wanted: Brief paragraph regarding the reasoning behind adding this tool to the GVCS

Relevant Links

Building Your Own Dairy Milking Unit

Conceptual Notes

Wanted: Ifs, ands and buts.

Development

Overview

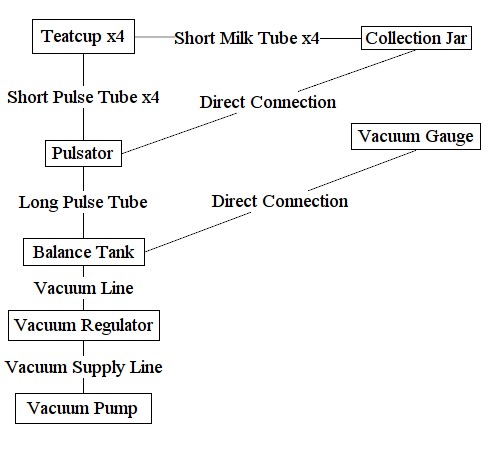

- Milking Unit are the components that attach to the dairy cow and produce pulses for alternating vacuum/atmospheric air entry cycles

- Vacuum System is the components that produce and regulate the vacuum level

- Milk Flow System is the components that accumulate milk and pump it to a bulk tank

- See page 8 of link "Milking and Milk Quality" for a full diagram

- Simplified Dairy Milker

Milking Unit

- Includes the pulsator, teatcups, short and long milk tubes, short and long pulse tubes, and the claw.

- Claw

- Simply a component that connects ports to more ports

- From 1 port for the long milk tube to 4 ports for the short milk tubes

- From 1 port for the long pulse tube to 4 ports for the short pulse tubes

- Teatcup

- The teatcup is comprised of a shell and liner, the liner being attached to the dairy cow's teats during the milking process.

- Do we want metal or hard plastic teat cup shells? Assume stainless steel for its durability

- Do we want rubber or silicone teat cup liners? Assume silicone for its durability

- Do we want an integrated or separate short milk tube? Assume separate

- The teatcup has an opening for the short milk tube, one for the short pulse tube, and one for the liner mouthpiece

- The teatcup liner is comprised of a mouthpiece and barrel

- Pulsator

- Small machine that alternates between applying vacuum at the teatcups and admitting air at atmospheric pressure to the teatcups

- Normal pulsator rate (rate of opening and closing) is 60 per minute. Pulsation ratio (vacuum time to air entry time) can be 50:50.

- 1 port to pulse line to vacuum reservoir

- 1 port to long pulse tube to claw

- 1 port to atmosphere

- Runs on DC current, usually 12V or 24V

Vacuum System

- Vacuum Gauge

- Placed inline with the pulsation lines and also between the vacuum reserve tank and vacuum regulator

- Measures vacuum pressure

- 2 ports

- Vacuum Reserve Tank

- Distributes vacuum to the pulsation header lines and milk header line

- Buffers the vacuum level for when air enters the vacuum system

- 1 port for milk header line

- 2 ports for pulsation header lines

- 1 port for main vacuum supply line

- Vacuum Pump Filter

- Prevents particulates from entering the vacuum pump

- 1 port for intake to main vacuum supply line

- 1 port for outtake to line to vacuum pump

- Vacuum Pump

- Applies a partial vacuum in the system

- 1 external port

- 1 vacuum port

- Vacuum Regulator

- Prevents vacuum level from increasing excessively by allowing air into the vacuum system when the vacuum level reaches a preset value

- 1 external port

- 2 inline ports

- Vacuum Relief Valve

- Prevents vacuum level from increasing excessively by allowing air into the vacuum system when the vacuum level reaches a preset value in case the vacuum regulator fails

- 1 external port

- 2 inline ports

- Sanitary Trap

- Separates the air-only vacuum system from the milk collection system

- Prevents liquid and particulates from the milk collection system entering the vacuum system

- 1 port to vacuum system

- 1 port to milk flow system

Milk Flow System

- Milk Receiver Jar

- Collects milk from the milking units

- 1 port to vacuum system

- 2 ports to milk pipelines

- 1 port to milk pump

- Milk Pump

- Pumps milk from the milk receiver jar to the bulk tank

- 1 port to milk receiver jar

- 1 port to milk filter

- Milk Filter

- Prevents particulates from entering bulk tank

- 1 port to milk pump

- 1 port to bulk tank

- Bulk Tank

- Main collection container for milk

- 1 port to milk filter

- 1 port to sink for yielding milk

Design

- Requirements

- Speed

- Throughput

- Weight

- Size Constraints

- Feed stock

- Design Description

- Calculations

- Drawings and Diagrams

- Concept and Alternatives

- Full Design Views

- Cut-away Views

- Exploded Parts View

- 3D Renders

- Decisions

- Project Team

Industry Standards

| Industry Standard | GVCSTool |

|---|

Funding

Wanted: List of expenses for prototyping and documenting GVCSTool

Peer Reviews

Wanted: Peer reviews from the scientific community regarding the R&D of GVCSTool

Experiments and Prototypes

Wanted: Empirical data on performance