Dairy Milker/Research Development

| Dairy Milker | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Research

- Dairy Milker Function is to express milk from dairy cows, buffalo, goats or sheep. The milker described in this article is known as a "bucket milker" which may be set up to milk one or two dairy animals at a time, evacuating the milk from the udder into a specially designed pail.

Theory

- Pulsator speed - is the number of vacuum/air cycles that the pulsator achieves per interval of time. The pulsator speed should be around 50-60 per minute.

- Pulse Ratio - is the ratio of time alloted to vacuum and atmospheric air entry per pulsator cycle. The pulse ratio should be around 50:50.

- Regulated Vacuum Pressure - is the vacuum pressure level at which the dairy milker normally operates. The regulated vacuum pressure should be around 11-13 inches of mercury.

- Vacuum Fluctuation - is the difference between vacuum pressure applied to the teats at different times. The vacuum fluctuation should not exceed 2 inches of mercury.

Relevant Links

Building Your Own Dairy Milking Unit

Conceptual Notes

Development

Overview

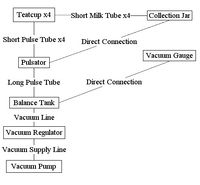

- Milking Unit are the components that attach to the dairy cow and produce pulses for alternating vacuum/atmospheric air entry cycles

- Vacuum System is the components that produce and regulate the vacuum level

Milking Unit

- Inflation - is the component that attaches onto the teats of the dairy animal. It provides a seal for the vacuum as the milk is expressed from the udder. The inflation lines the teatcup and can be made of rubber or silicone. Silicone inflations tend to be longer-lasting. The inflation has two segments, a mouthpiece and a barrel. The mouthpiece makes contact with the teats while the barrel fits inside the teatcup shell.

- Teatcup Shell - is the component that contains the inflation. The teatcup shell is a hollow cylinder with an opening at the top for the mouthpiece of the inflation, an opening at the bottom for the barrel of the inflation, and an opening at the side for connection to the short pulse tube. For durability, the teatcup shell should be made of stainless steel or foodgrade heavy duty clear plastic. Shells and inflations are inexpensive and can be purchased in varying sizes from many dairy suppliers.

- Short Milk Tube - is the component that connects the bottom of the teatcup liner barrel to the top of the collection bucket. Milk flows from the teatcup liner through the short milk tube to the collection bucket.

- Short Pulse Tube - is the component that connects the side of the teatcup shell to the pulsator.

- Collection Bucket - is the component that accumulates the milk yielded from the dairy animal.

- Collection Lid - is a round narrow metal disk that covers the top of the collection bucket, mounts the pulsator, and connects to the short milk tubes.

- Collection Gasket - is a round rubber component that seals between the collection bucket and collection lid.

- Pulsator - is the machine that alternates between applying vacuum at the teatcups and admitting air at atmospheric pressure to the teatcups

- Normal pulsator rate (rate of opening and closing) is 60 per minute. Pulsation ratio (vacuum time to air entry time) can be 50:50.

- 1 port to pulse line to vacuum reservoir

- 1 port to long pulse tube to claw

- 1 port to atmosphere

- Runs on DC current, usually 12V or 24V

- Long Pulse Tube - is the component that connects the vacuum reservoir to the pulsator.

Vacuum System

- Vacuum Gauge - measures the vacuum level in the vacuum system and outputs an analog reading.

- Vacuum Reserve Tank - can be a series of pipes that distribute vacuum to the pulsator and buffer the vacuum level when air enters the vacuum system.

- Vacuum Pump Filter - is the component connected to the intake of the vacuum pump that prevents particulates from entering and damaging the vacuum pump.

- Vacuum Pump - is the component that produces a vacuum in the vacuum system.

- Vacuum Regulator - prevents vacuum level from increasing excessively by allowing air into the vacuum system when the vacuum level reaches a preset value

- Vacuum Relief Valve - prevents vacuum level from increasing excessively by allowing air into the vacuum system when the vacuum level reaches a preset value in case the vacuum regulator fails

- Sanitary Trap - prevents liquid and particulates from the milking unit entering the vacuum system

Design

- Requirements

- Speed

- Throughput

- Weight

- Size Constraints

- Feed stock

- Design Description

- Calculations

- Drawings and Diagrams

- Concept and Alternatives

- Full Design Views

- Cut-away Views

- Exploded Parts View

- 3D Renders

- Decisions

- Project Team

Industry Standards

- Pasteurized Milk Ordinance

| Industry Standard | GVCSTool |

|---|

Funding

Wanted: List of expenses for prototyping and documenting GVCSTool

Peer Reviews

Wanted: Peer reviews from the scientific community regarding the R&D of GVCSTool

Experiments and Prototypes

Wanted: Empirical data on performance

Experimental Results

Prototype Notes, Observations, etc.

Industry Standard Milk Tank Diagram

Pulsator

The function of pulsators is to alternate the space between the teat cup shell and teat cup liner between a partial vacuum (milking phase) and atmospheric air pressure (rest phase). During the milking phase, the space between the inflation and shell, and the space inside the inflation have the same partial vacuum. This causes the inflation to open and milk to flow from the teat. Milk flows from the teat because the pressure inside the udder is greater than that outside the teat end.

During the rest phase, air at normal atmospheric pressure,enters between the shell and inflation. Due to the partial vacuum inside the inflation, the inflation collapses around the teat. The pressure of the collapsed inflation helps massage the teat, preventing congestion of blood and body fluids in the teat skin and tissue.

The number of times per minute that the pulsator alternates between the milking and rest phase is called the pulsation rate. Rates vary from about 40 to 80 pulsations per minute, depending upon the manufacturer. A rate between 50 to 60 is recommended.

The ratio of time the inflation is in the milking phase to the time it is in the rest phase is called the pulsation ratio. Ratios vary by manufacturer, from 50:50 to about 70:30. Cows will usually milk slightly faster with a wider ratio. However, the longer milk phase and shorter rest phase may cause teat end trauma and damage if the milking equipment is not working properly and good milking practices are not followed. Ratios closer to 60:40 are less likely to contribute to problem situations.

The closing patterns of the inflations varies by manufacturer. Some have all four inflations of a claw closing at once (simultaneous), while others have an alternating pattern (only two inflations close at a time). The alternating pattern results in less claw flooding in units with a small claw. In units with larger claws that do not flood, alternating pulsation is not as important. Claw flooding (filling) is not desired, for it causes vacuum fluctuation at the teat end. This, in turn, can result in teat end injury and the back flushing of milk into the teat. The introduction of mastitis causing organisms into the udder can occur in such a situation.

Pulsators are controlled either by electricity or air (pneumatically) or a combination of the two. Electrically controlled units are preferred because of their more consistent action. Pneumatically operated units are more unreliable and require more maintenance. It is recommended that when four or more units are being used, the electric pulsators be wired on two or more circuits to prevent them from being in the same phase. This can help prevent cyclic vacuum fluctuations on the pulsator line.

A new type of milking unit from New Zealand has the pulsator mounted directly on top of the claw. It operates by vacuum and not by air or electricity. At this time, research studies evaluating the units are lacking.

Discussion: Gabi and Yoonseo

Here's some industry specs:

http://img.weiku.com/waterpicture/2011/10/25/10/Vacuum_Pulsator_For_Milking_Machine_634606132029527276_1.jpg

Some parts that Hamby sells, all put together would make a complete pulsator (but very very expensive): http://hambydairysupply.com/xcart/product.php?productid=17568&page=1 http://hambydairysupply.com/xcart/product.php?productid=541 http://hambydairysupply.com/xcart/product.php?productid=1555&page=1

The easy part of what we could build is the control electronics. Having 4 channels that alternative on/off according to a certain rhythm in order to switch on/off 4 electronic things is super-easy. In fact it's what is being used for the CEB Press. The tough part is making the actual things that are supposed to switch on and off.

http://www.copulsation.com/copulsation.htm

Looks like the switch parts are just 2 solenoids, 2 plungers, a frame, and 2 ports. One plunger for vacuum and one plunger for air. The vacuum plunger-frame interface might be a bit tricky to get right but overall looks quite doable.

General Notes

- Alternative materials:

- 60 cc syringe shell for teat cups

- Pedal Powered Vacuum Pump - Runs at about 11 PSI, which is perfect, but can it supply constant pressure while the pulsator is running 55-60 bpm?

Resources:

- http://www.smallholderhollow.com/projects/diy-milking-machine/

- http://www.homesteadingtoday.com/livestock-forums/cattle/289714-one-cow-milking-machine-question.html

- http://www.goatfinder.com/goat_milk_machine.htm

- http://www.countrysidemag.com/issues/90/90-3/Steve_Shore.html