Rotary encoder: Difference between revisions

| Line 31: | Line 31: | ||

=== OSE Encoder Concepts === | === OSE Encoder Concepts === | ||

''note: this page was started because I wanted a place to document some brainstorming I had done on | ''note: this page was started because I wanted a place to document some brainstorming I had done on the rotary capacitance encoder design. Please add other conventional and/or unconventional concepts as appropriate -- ChuckH'' | ||

====Rotary capacitance encoder ("Capacitive resolver")==== | ====Rotary capacitance encoder ("Capacitive resolver")==== | ||

Revision as of 16:03, 1 October 2011

Rotary Encoder

Overview

A rotary encoder converts mechanical rotation of a shaft to electronic signals which can be processed -- typically by an Arduino microcontroller in this context -- for display, machine control, or feedback purposes.

Mature technologies (commercially available) for rotary encoders include

- optical incremental (quadrature)

- optical absolute (parallel, gray code)

- mechanical contact (brush)

- AC magnetic (resolver, synchro, inductosyn)

- DC magnetic (hall effect)

- AC Capacitive

An enormous variety of products are available over a huge range of performance parameters, including

- Resolution

- Accuracy

- Rotational speed

- size (outside diameter, shaft diameter, thru hole diameter)

- power requirements

TBD: links to existing commercial products US Digital (an encoder vendor).

GVCS applications

OSE Encoder Concepts

note: this page was started because I wanted a place to document some brainstorming I had done on the rotary capacitance encoder design. Please add other conventional and/or unconventional concepts as appropriate -- ChuckH

Rotary capacitance encoder ("Capacitive resolver")

This idea addresses a goal to design a high-resolution, fairly accurate encoder that can be made with a minimum of precision equipment (e.g. manual layout, simple lathe work) and minimum purchased electronics outside the "OSE standard" Arduino platform. This design has a base resolution of 48 cycles per revolution and should support ~100x electronic interpolation for a resolution of 1/4800 rev (0.075 degree).

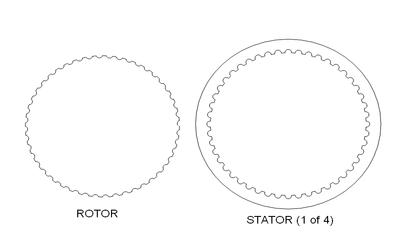

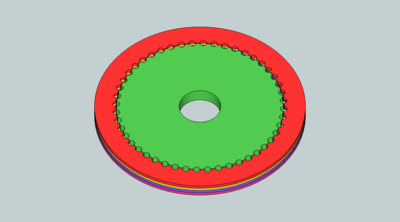

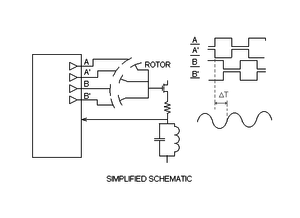

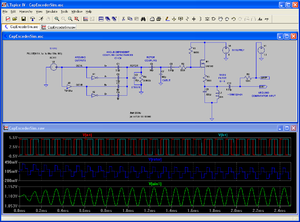

The design includes 4 stationary outer electrode rings, offset 1/4 of a tooth pitch, driven by 2-phase square waves A+ A- B+ B-. One rotating inner electrode. All electrodes are splined (e.e. toothed). Buffer the hi-z rotating electrode signal, filter with tuned circuit, and measure its phase to interpolate within 1 spline tooth pitch. (This has been called the "phase analog technique" when used with resolvers. [1]) Electronics can be arduino. Multiple encoders can share drive waveform. Special electronic parts: 1 FET(buffer), inductor, capacitor. Expected carrier freq: 1-10kHz. Use arduino capture/compare function to measure time of zero crossings.

Lay out circle of equally spaced hole centers (say ~3" BC, 48 holes on 7.5-degree spacing) on jig plate. Can use compass/straightedge techniques at large radius. Transfer hole pattern to 4 stator sheets 1/16 thk and one rotor sheet 1/4 thk. Bore ID of stator sheets (as stack). Turn OD of rotor sheet leaving .020 radial clearance. ID of rotor can be bored out to large clearance for large shaft if desired. Note that all parts must be insulated from each other and from ground.

Principles:

- Averaging over full circumference should reduce sensitivity to spline tooth pitch errors and mounting eccentricity.

- Sharply tuned filter should make rotor waveform approx true sinewave. Reactance modulation waveform depends on tooth geometry and is not precisely sinusoidal; empirically calibrate encoder.

Accuracy refinement: Lay out so stator tooth crest is inside bolt circle dia, making slight hourglass tooth profile. Consider this as an internal gear. Make another gear with fewer teeth, relatively prime to stator tooth count, that will mesh inside. Running these two gears in mesh with lapping compound should bring teeth into precisely uniform spacing. After lapping, clean 4 stators and assemble them as above.