TightWire Alignment: Difference between revisions

mNo edit summary |

|||

| Line 1: | Line 1: | ||

Tight wire alignment is a technique for measuring straightness of large equipment components. ([http://www.powerhousetool.com/align.htm example supplier]) It has a long history although it has been largely displaced by optical methods. It may be appropriate for creating straight movement axes in lathes, torch tables, and other machine tools. | Tight wire alignment is a technique for measuring straightness of large equipment components. ([http://www.powerhousetool.com/align.htm example supplier]) It has a long history although it has been largely displaced by optical methods. It may be appropriate for creating straight movement axes in lathes, [[CNC_Torch_Table | torch tables]], and other machine tools (especially appropriate for [[Shonda_Research |concrete-bed, grouted-ways designs]]). | ||

== Principle == | == Principle == | ||

Revision as of 19:27, 18 December 2011

Tight wire alignment is a technique for measuring straightness of large equipment components. (example supplier) It has a long history although it has been largely displaced by optical methods. It may be appropriate for creating straight movement axes in lathes, torch tables, and other machine tools (especially appropriate for concrete-bed, grouted-ways designs).

Principle

A wire stretched between two points establishes a nearly straight line. Gravity causes a sag which can be predicted accurately if the tension (e.g. from a hanging weight) and wire material are known. The distance from the wire to an object of interest (e.g. a guideway, bearing housing, travelling slide, etc) is usually measured manually with a micrometer device which "beeps" on electrical contact with the wire.

Optical sensor

As an alternative to manual micrometers, a close-up camera may observe the wire position. Kevan Hashimi at Open Source Instruments describes such an instrument for scientific work. Here we describe a low-cost adaptation to the machine-alignment task.

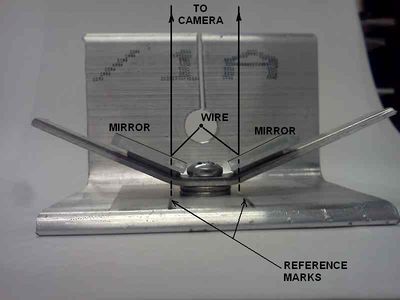

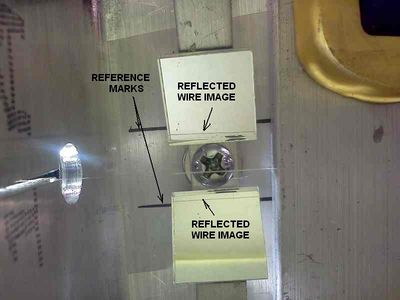

This sensor relies on a single camera looking at images of the tight wire in two small mirrors. The assumption is that some kind of electronic camera (webcam, cell phone, etc) will be available on an ad hoc basis, but is not permanently dedicated to the instrument.

Proof of concept

For testing I used an LG Optimus cell phone camera. This camera can capture video.

Parts of the optical sensor:

Assembled:

Set up for checking lathe way straightness:

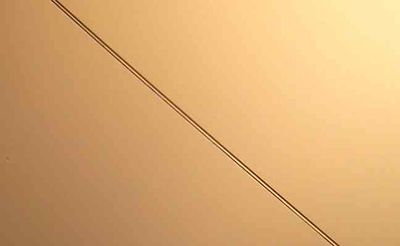

(The "wire" is nylon monofilament sewing thread, 0.005 inch diameter)

Sample camera frame:

Clearly some repositioning of the mirrors would help. Ideally we could get a reflected image comparable to this:

Image processing tests TBD.