Induction Furnace Power Electronics Design Rationale and Specification: Difference between revisions

Jump to navigation

Jump to search

(→Links) |

|||

| Line 2: | Line 2: | ||

=Design Rationale= | =Design Rationale= | ||

This specification is for the power electronics and controls component only - other components being the heating coil with cooling system, and the melt chamber proper. It includes feedback on temperature and maximum-power-delivery tracking to the melt. This is a frequency and power level selectable power supply with automatic feedback for controlling an optimum melt sequence. | |||

The concept is to design a stackable power supply where power supply modules may be stacked - just like the stackability of the [[Stackable Inverter]]. | |||

=Specifications= | =Specifications= | ||

Revision as of 04:40, 20 January 2012

See also [[1]]

Design Rationale

This specification is for the power electronics and controls component only - other components being the heating coil with cooling system, and the melt chamber proper. It includes feedback on temperature and maximum-power-delivery tracking to the melt. This is a frequency and power level selectable power supply with automatic feedback for controlling an optimum melt sequence.

The concept is to design a stackable power supply where power supply modules may be stacked - just like the stackability of the Stackable Inverter.

Specifications

- Rated Power output: 12.5 KW (running from a 2 ton battery bank of 3 forklift batteries at 24v each for testing purposes)

- Output Voltage: 300 V or whatever is required for an efficient melt

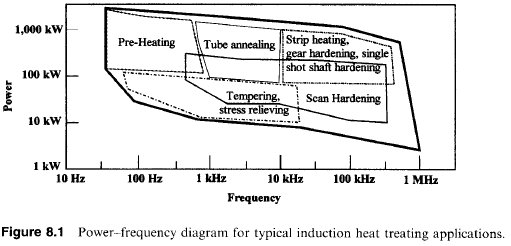

- Output Frequency: 1 KHz - 30 KHz

- Input voltage: 24 VDC or 72 VDC

- Input current: 500 A or 170 A

- Duty cycle: 100%

- Efficiency: >90%

Particulars

- IGBT Technology and control

- Temperature controllable