Bioplastics: Difference between revisions

No edit summary |

No edit summary |

||

| Line 8: | Line 8: | ||

Combined with [[Plastic Extrusion & Molding|plastic extrusion and molding]] machines such as [[RepRap]], bioplastics enable a local manufacturing process that starts with food waste or soil and creates computer and phone casings, car and machine parts, toys and tools, screws and sculptures. | Combined with [[Plastic Extrusion & Molding|plastic extrusion and molding]] machines such as [[RepRap]], bioplastics enable a local manufacturing process that starts with food waste or soil and creates computer and phone casings, car and machine parts, toys and tools, screws and sculptures. | ||

=Bioplastics of interest= | ==Bioplastics of interest== | ||

'''Cellophane''' is reformulated cellulose (wood), produced via an acid and base dunk of sawdust. This may be used in glazing. Car bodies may be made; the original car bodies for Ford were soybean-derived bioplastics. | '''Cellophane''' is reformulated cellulose (wood), produced via an acid and base dunk of sawdust. This may be used in glazing. Car bodies may be made; the original car bodies for Ford were soybean-derived bioplastics. | ||

| Line 33: | Line 33: | ||

This page is meant to organize the information being collected on bioplastic production and proposed project plans. | This page is meant to organize the information being collected on bioplastic production and proposed project plans. | ||

Detailed background and status briefs of individual projects should be maintained on their own page. Information on the advantages and disadvantages of an "anabolic", organic, bioplastic | Detailed background and status briefs of individual projects should be maintained on their own page. Information on the advantages and disadvantages of an "anabolic", organic, bioplastic production process and details of the rational design of the overall process should be maintained on this page. Many materials specified in this proposal could be replaced such as sorghum is just an example of a starting feedstock. Alternative routes are encouraged and should be given their own page and linked to this page. | ||

=Plastics of interest= | =Plastics of interest= | ||

| Line 39: | Line 39: | ||

==Polylactic acid== | ==Polylactic acid== | ||

==Polycellulose== | ==Polycellulose== | ||

==Moldable Mycelium== | |||

=Feedstock= | =Feedstock= | ||

Preferred bioplastic feedstocks are plants high in sugar content that is accessible to fermenting microorganisms. | |||

==Sorghum== | |||

Sorghum is a feedstock of interest for bioplastic production due to its high productivity in producing sugars that can be fermented to either ethanol or lactic acid. The remaining bagasse contains cellulose which can be extracted after acid steam pretreatment as cellulose acetate. The remaining biomass can be burned for thermal energy or composted. Sorghum is a fairly resilient crop and can be planted on less desirable land. | Sorghum is a feedstock of interest for bioplastic production due to its high productivity in producing sugars that can be fermented to either ethanol or lactic acid. The remaining bagasse contains cellulose which can be extracted after acid steam pretreatment as cellulose acetate. The remaining biomass can be burned for thermal energy or composted. Sorghum is a fairly resilient crop and can be planted on less desirable land. | ||

==Corn== | |||

==Woody biomass/sawdust== | |||

=Microorganisms= | =Microorganisms= | ||

==Ethanol== | ==Ethanol== | ||

==Lactic acid== | ==Lactic acid== | ||

==Acetic acid== | |||

=Hardware= | =Hardware= | ||

The GVCS contains the tools necessary to produce a feedstock crop. Hardware necessary for the production of refined monomers and conducting chemical reactions are proposed for inclusion in GVCS III and include a fermentor and fluid bed reactor (FBR). | |||

==Fermentor== | ==Fermentor== | ||

==Fluid Bed Reactor== | ==Fluid Bed Reactor (FBR)== | ||

Revision as of 16:04, 15 May 2012

Main > Materials > Bioplastics

Introduction

Bioplastics are the perfect addition to an integrated farm and forestry operation. An effective open-source method of producing bioplastics will allow communities to be self-sufficient in the raw materials for many modern comforts. Bioplastics promise to replace the many useful products we currently extract from oil.

Combined with plastic extrusion and molding machines such as RepRap, bioplastics enable a local manufacturing process that starts with food waste or soil and creates computer and phone casings, car and machine parts, toys and tools, screws and sculptures.

Bioplastics of interest

Cellophane is reformulated cellulose (wood), produced via an acid and base dunk of sawdust. This may be used in glazing. Car bodies may be made; the original car bodies for Ford were soybean-derived bioplastics.

Polylactic acid can be made by fermenting starch.

Polyethelene can be fabricated from ethylene (which can be relatively easily produced from ethanol).

Mycelium can be placed in a mold with grain husks, wheat straw or any of a wide variety of other biomass (with different end product results) and be made into a variety of useful products, including a durable closed cell foam substitute. See: [1], [2] [3](these refer to the same product and company). Work need to be done open-sourcing this process - what mycelium are used? Where can we get spores? What can we make? We may be able to obtain some and identify it under a microscope (wary of nto infringing patents of course; maybe a similar but lower performing mycelium that is not patented could suit our purposes for building insulation etc.)

Where to get

- people of ultimachine.com made their way to natureworks LLC to get PLA (Polylactide), called ingeo (tm)

- makemendel.com offers PLA parts for Mendel since december 2011

- Shenzhen Esun Industrial Co. Ltd. (formerly Shenzhen Brightchina) produces PLA and PCL

- eastern bioplastics, biodegradable plastics from poultry feathers

- FKuR Kunststoff GmbH

- Freitec Kunststoffe GmbH

More readings

Proposed OSE agroecological approach to bioplastic production

Bioplastics come in a variety of forms and will most likely be an important material in the post-scarcity economy. Bioplastics are polymers from a biological source including polyesters, olefins, and other organic chains that can be extruded into a variety of shapes. Plastics have been in production for hundreds of years from both organic sources and petroleum sources. An agroecological approach will utilize local feedstocks to produce refined subunits for polymerization and use life cycle analysis and appropriate technology to maximize efficiency on a small scale. An agroecological approach will build up polymers as opposed to petroleum based methods that start by breaking down materials. By starting with high purity substrates purification machinery can be minimized and hardware greatly reduced in size.

This page is meant to organize the information being collected on bioplastic production and proposed project plans. Detailed background and status briefs of individual projects should be maintained on their own page. Information on the advantages and disadvantages of an "anabolic", organic, bioplastic production process and details of the rational design of the overall process should be maintained on this page. Many materials specified in this proposal could be replaced such as sorghum is just an example of a starting feedstock. Alternative routes are encouraged and should be given their own page and linked to this page.

Plastics of interest

Polyethylene

Polylactic acid

Polycellulose

Moldable Mycelium

Feedstock

Preferred bioplastic feedstocks are plants high in sugar content that is accessible to fermenting microorganisms.

Sorghum

Sorghum is a feedstock of interest for bioplastic production due to its high productivity in producing sugars that can be fermented to either ethanol or lactic acid. The remaining bagasse contains cellulose which can be extracted after acid steam pretreatment as cellulose acetate. The remaining biomass can be burned for thermal energy or composted. Sorghum is a fairly resilient crop and can be planted on less desirable land.

Corn

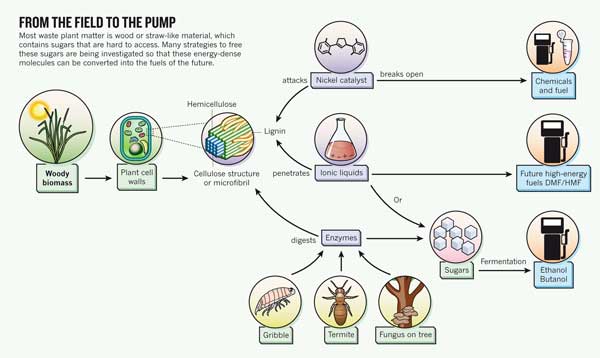

Woody biomass/sawdust

Microorganisms

Ethanol

Lactic acid

Acetic acid

Hardware

The GVCS contains the tools necessary to produce a feedstock crop. Hardware necessary for the production of refined monomers and conducting chemical reactions are proposed for inclusion in GVCS III and include a fermentor and fluid bed reactor (FBR).