Terminal Case: Difference between revisions

No edit summary |

|||

| Line 3: | Line 3: | ||

Version 4: | Version 4: | ||

Screw fastening would reduce the mounting volume of the terminal case considerably. But the trick is enabling screw fastening while retaining the ability to use C-Clamp compression too. | |||

The cable glands are fine but there's a mounting issue where the aluminum is too thick for the short mounting thread of the cable gland. Also a multi-cable issue associated with fact that a cable gland can only seal properly with a single cable. | |||

Version 3: | Version 3: | ||

Revision as of 07:50, 8 December 2012

Introduction

Version 4:

Screw fastening would reduce the mounting volume of the terminal case considerably. But the trick is enabling screw fastening while retaining the ability to use C-Clamp compression too.

The cable glands are fine but there's a mounting issue where the aluminum is too thick for the short mounting thread of the cable gland. Also a multi-cable issue associated with fact that a cable gland can only seal properly with a single cable.

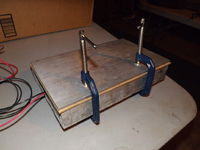

Version 3:

File:Terminalcase35.jpg File:Terminalcase36.jpg

The objective is a waterproof, corrosion-resistant, chemical-resistant, impact-resistant, thermo- resistant, EMP-resistant, lightweight, accessible, versatile, modular container for electronics and other hardware.

Materials

Aluminum Plate 1/4" x 7" (Speedymetals)

Aluminum Bar 1/4" x 3" (Speedymetals)

Pure Tan Gum Rubber 1/8" x 12" x 24"

Aluminum Plate 1/4" x 7" x 72" OR Aluminum Plate 1/4" x 12" x 36"

Pure Tan Gum Rubber 1/8" x 12" x 24"

Build Documentation

Old Info

Version 2 with screw mounting: