Steam Engine Construction Set

Introduction

Steam engines are a robust energy source which played a main role in the industrial devolution, and may now be a viable candidate as an engine of the post-industrial revolution. Tinytech in India manufactures steam engines for various industrial swadeshi applications, primarily in India. We believe that steam engines, coupled to flash steam generators, are also relevant as an appropriate technology choice in the 'developed' world. As such, we are proposing an open source steam engine project, to deliver an appropriate technology, modern steam engine:

- Open design

- Scalable in power from 5 to 100 horsepower

- May utilize electronic valving for mechanical simplification

- May be coupled direcly to linear hydraulic pump - feasibility study required

In particular, Factor e Farm is interested in utilizing these steam engines in the LifeTrac line of tractors, cars, and solar turbine electrical generators.

Design

Engine

Engine Valve Design

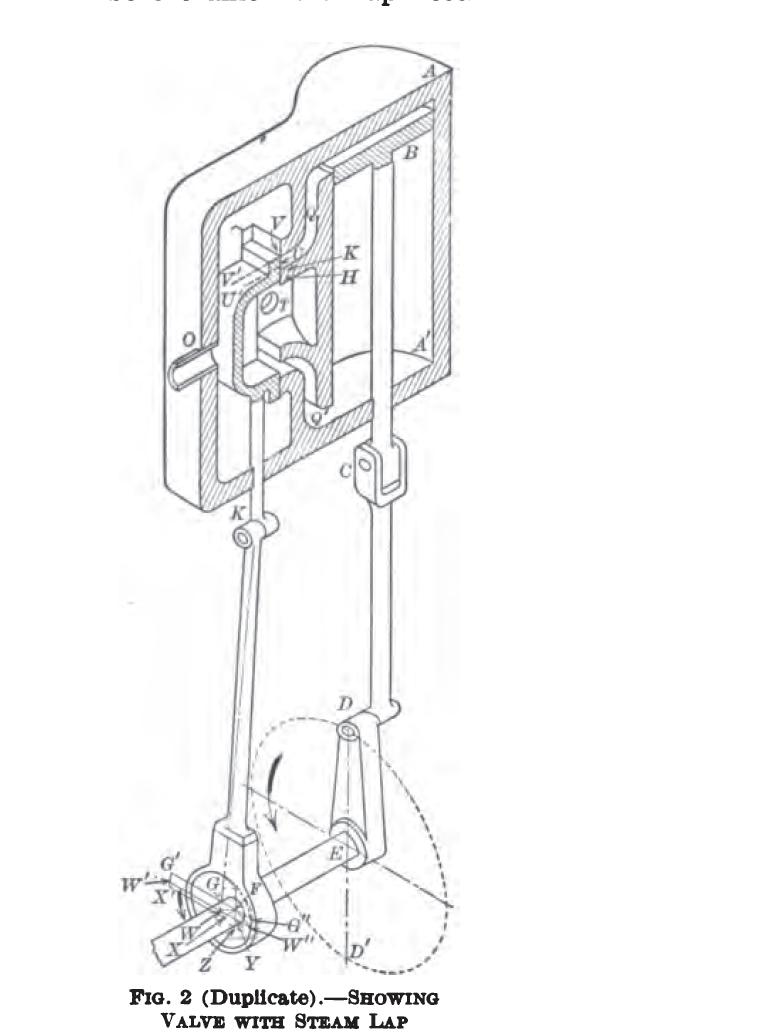

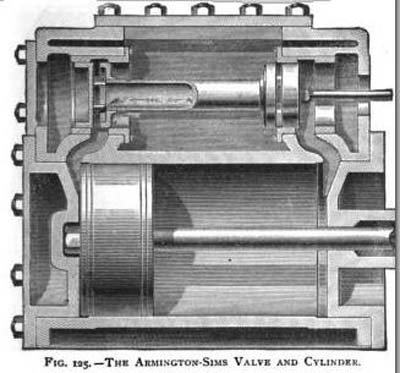

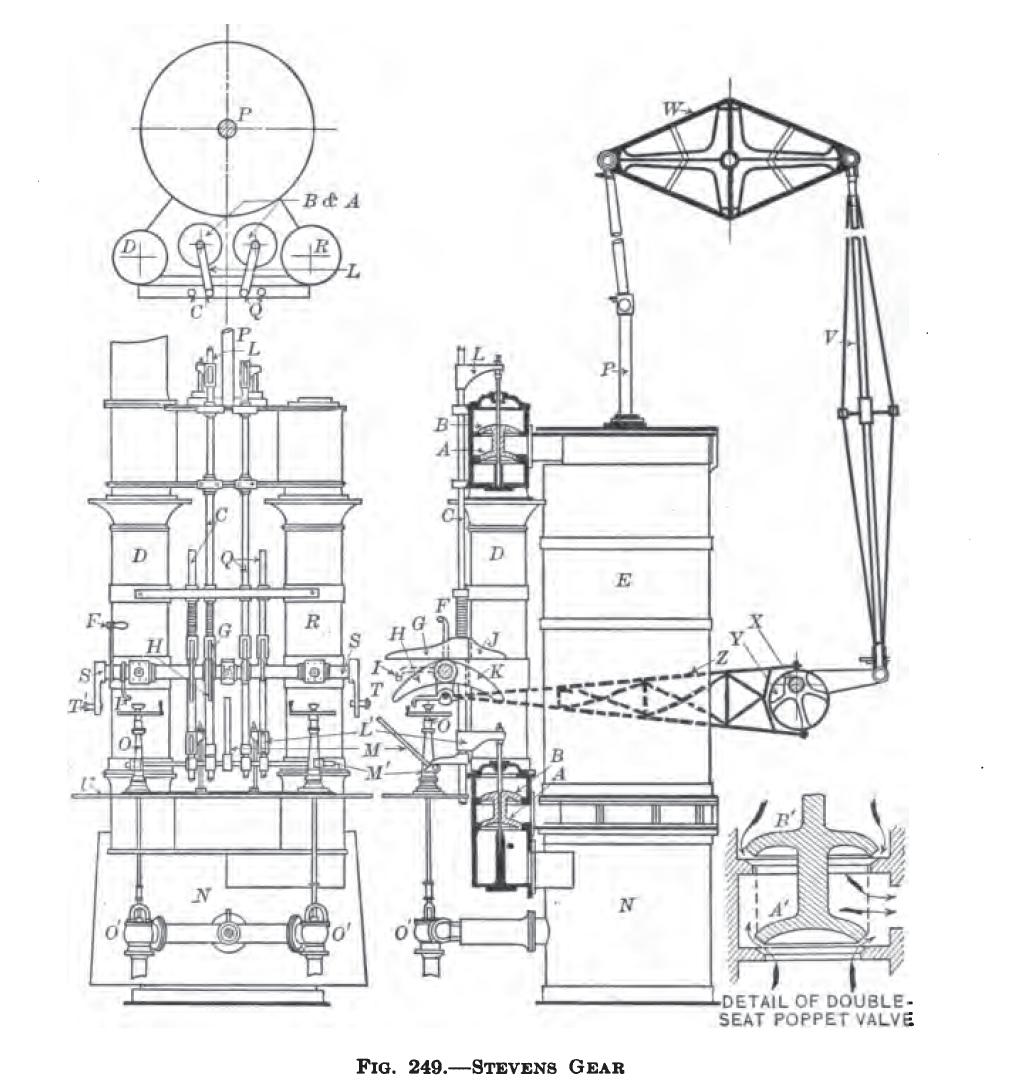

There are three common styles of conventional valves in steam engines they are the slide valve, piston slide valve, and cam actuated poppet valve.

Each of these has their own advantages and disadvangteous often depending on steam conditions and desired durability. Please consult an engineering manual such as this http://books.google.com/books?id=NsNCAAAAIAAJ&printsec=frontcover&dq=valves+and+valve+gears&as_brr=1 for a detailed discussion of this.

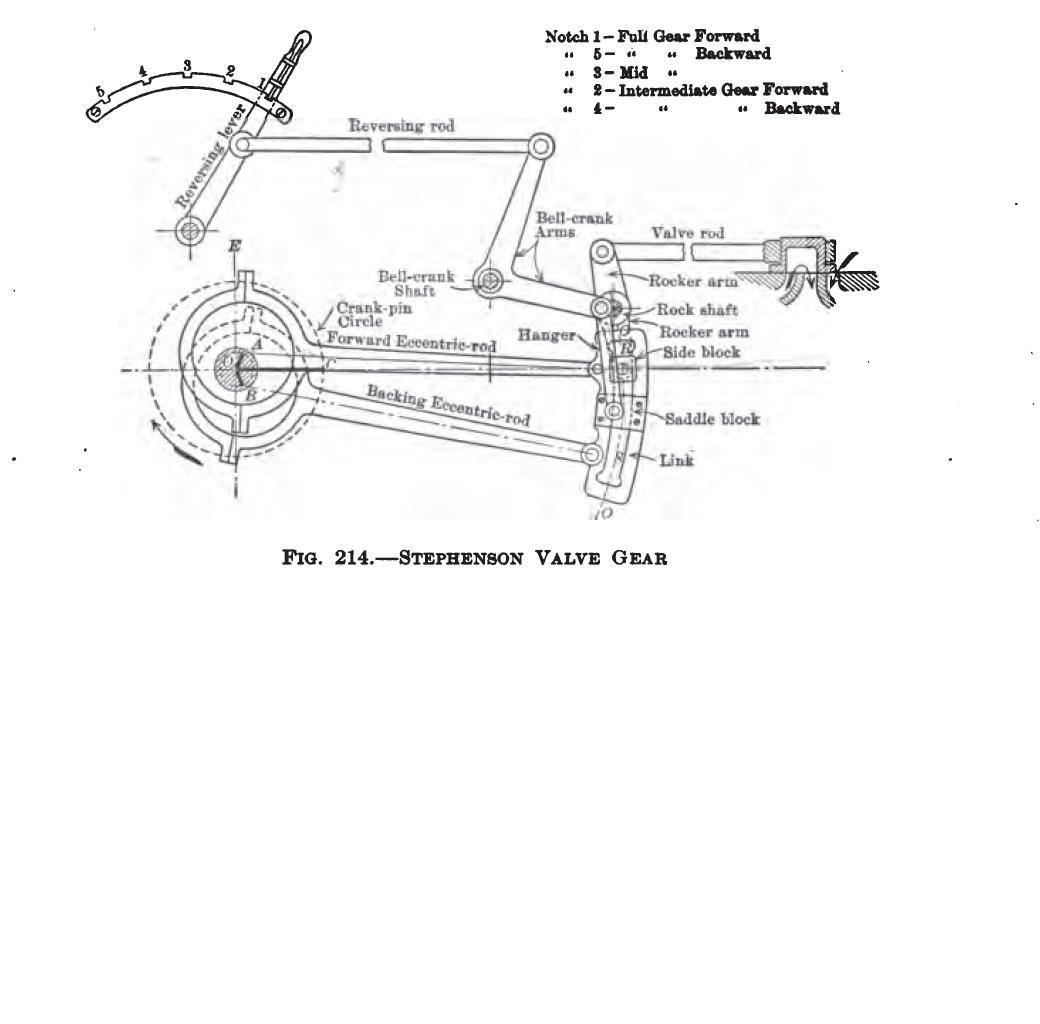

For the simple valves shown above it is not possible to vary the steam cutoff ratio during operation. This usually detrimentally impacts efficiency as one has to set the cutoff ratio higher than needed to keep the engine from stalling during load variation. For this reason a multitude of valve gears were developed for the three basic types of valve designs. The valve gears allow for the adjustment of the cutoff ratio during operation.

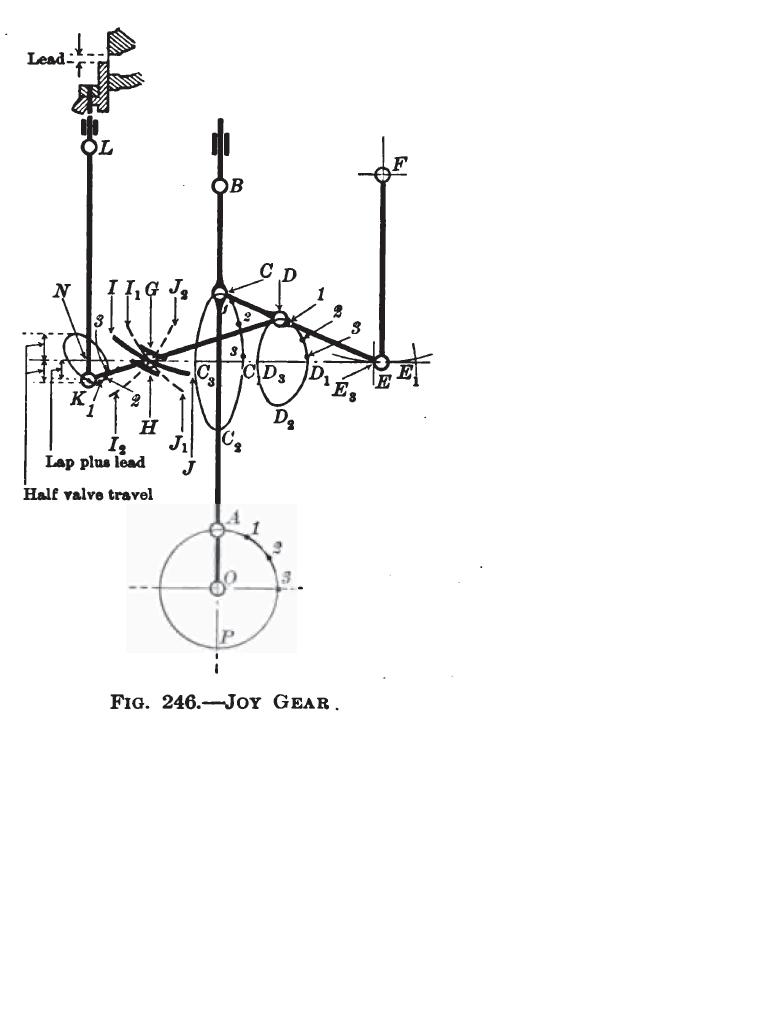

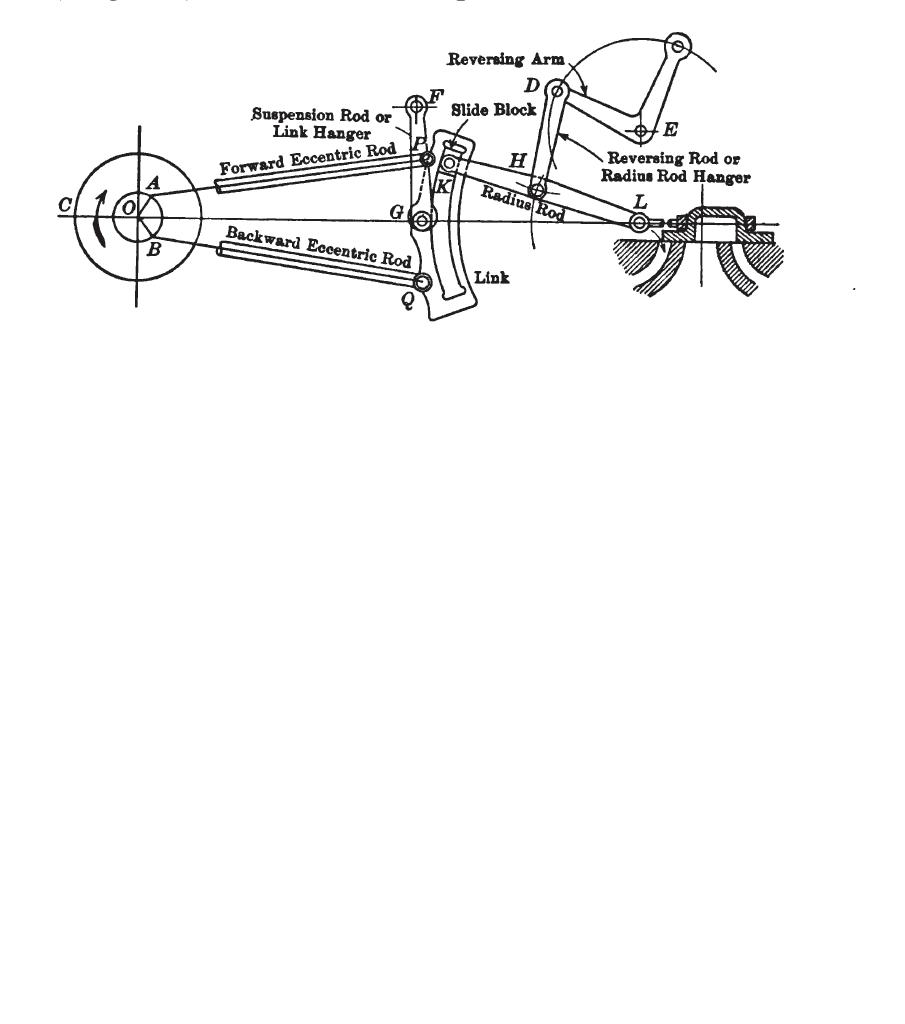

Slide Valve and Piston Slide Valve Valve Gears

Poppet Valve Valve Gears

Typical Engines

Typical steam engine cylinders are made from cast iron. (What is the best metal to use for a steam engine?) Given that water is the working fluid, lubrication is required in the cylinder. (Is there any way to prevent corrosion otherwise?)

- Cylinder - cylinder is made from cast iron.

- To cast this cylinder from scrap iron, use a (how many?) pound melt, and use a simple melting furnace such as (here?)

The simplest way to cast a cylinder

Azuredu 03:43, 27 February 2009 (PST) Suggestion. To start with, why not try to adapt a recovered moto engine.

skaar: try iron gas pipe?

jerryshaw: it may not be fully feasible yet, or maybe it already is, but high temperature plastics may actually be usable. Temperature and pressure is well below an internal combustion engine, and there are no plastic IC engines but we already have plastic intake manifolds right next to very hot components, say 400 degrees in the intake of some supercharged engines. If plastic works it would make for very inexpensive steam engines, as well as fairly light weight ones, making it easy to motorize things everywhere. They could be cheaply manufactured from a cooperative owned plant, or perhaps the plastic formulations could be tweaked over time to even eventually use bioplastic and be printed in your own RepRap machine! http://reprap.org/bin/view/Main/RepRap But until then don't entirely rule out plastic. It should at least work with basic steam, maybe not superheated steam. I have even heard of wood(!) being used to make a working steam engine (though I think it used iron piston rings, the piston and cylender and head were wood) although I wouldn't expect life to be terribly long.

- I think an aluminum/silicon alloy would be worth considering. It does not shrink much as it solidifies, and can be cast at a reasonable temperature, using plaster molds (lost wax or, when scaled up, a re-usable polyurethane master). It's also fairly strong, reasonably corrosion-resistant, can be used to make heat exchangers, and is widely available as scrap, e.g. aluminum engine blocks are made from a suitable alloy. David Gingery wrote some books that might be helpful.

Green Steam Engine

An alternative engine design that may be worthy of further evaluation can be found [1] here. It looks as though o-rings are used in place of traditional tight tolerance cast iron cylinder boring. Presumably this method is only good for low pressure and temperature steam. The linkage and valve system is highly innovated and would require no precision machining.

- Discussion of the Green steam engine:http://www.alternative-energy-news.info/green-steam-energy/ It does indeed seem that the o-ring method of sealing is incapable of handling high steam temps and pressures and the design is therefore inherently inefficient.

- Marcin says: I looked at this in detail 2 years ago, and purchased plans. When I asked for references of people who built this engine, the inventor did not provide me with any. I became suspicious about the effectiveness of the engine. Since then, I've heard reports from several sources that longevity and performance are questionable. In summary, if this worked as stated, we would see a large number of implementations on the internet. Since these are not to be seen, it does not appear to be a promising design.

Boiler

A simple boiler implementation involves a Babington_Burner heating the inside of a 6 inch metal pipe of 1/8" wall thickness. A 100 foot long coil of 1/2 inch steel tubing is placed inside this coil, and an electronically-controlled Valve delivery system (note: in steam engine case, the 'solar boiler' in last link is replaced by the above 100-foot coil of steel tubing.

Materials

- Stainless steel tubing at McMaster Carr, $130 for 100 feet of 1/2" tubing - type 304 stainless - item number 8989K67 at http://mcmaster.com

- 200 psi pressure relief valve http://www.grainger.com/Grainger/wwg/guideBrowse.shtml $60.80.

Boiler Fuel:

For transportation vehicles some biomass fuel energy densification is required. Pyrolisis fuels without elaborate processing look promising here is a brief summary of some methods http://www.ars.usda.gov/sp2UserFiles/Program/307/biomasstoDiesel/RobertBrown&JenniferHolmgrenpresentationslides.pdf

http://www.biomasscombustion.com/horizontal_grate_technology.htm

Stationary applications can probably get by with a simple style grate biomass boiler. http://www.biomasscombustion.com/horizontal_grate_technology.htm

Design Evolution

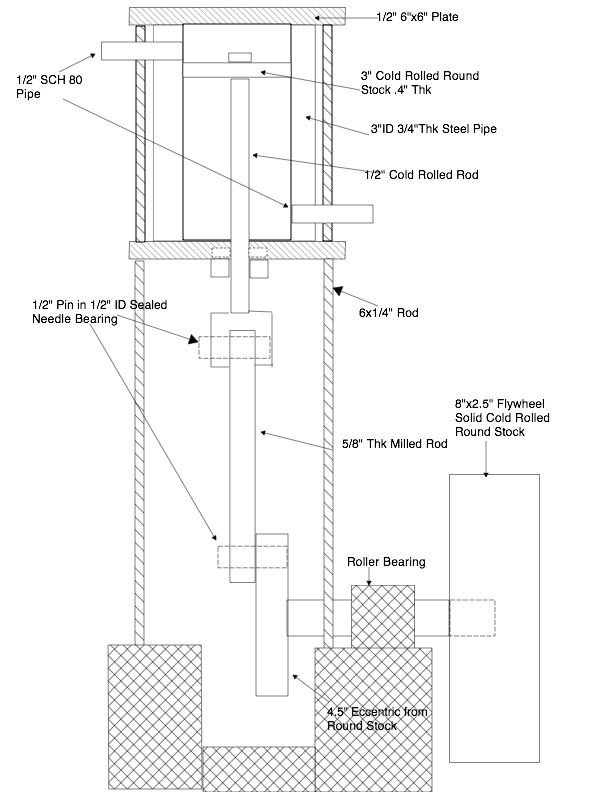

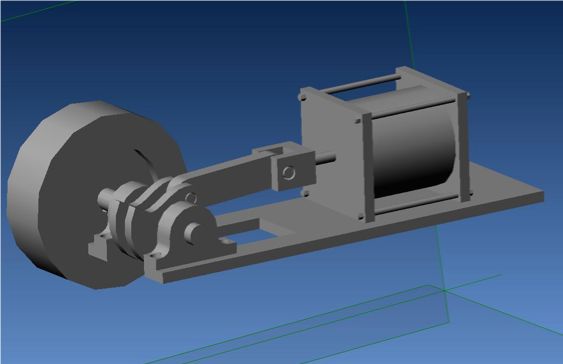

- Initial design, 1.8.09 -

Bill Of Materials To Date

QTY Description Price Location

- 1 Cylinder 38.03 [2]

- 1 Piston 3" x 5/8" Cold rolled Steel 9.97 [3]

- 1 Shaft 1" 13.01 [4]

- 2 Plate 1/2"x6"x6" 17.71 [5]

- 1 Flywheel 8"x2.5" Cold Rolled Steel 74.3 [6]

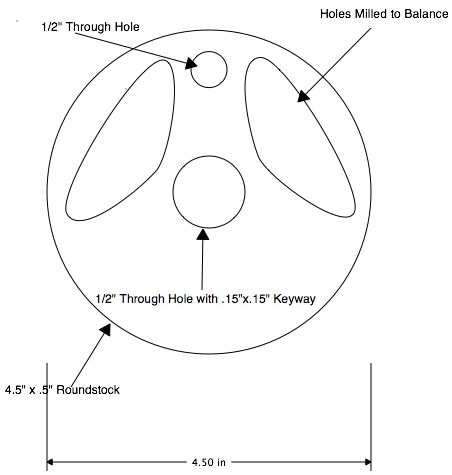

- 1 Eccentric 4.5" x .5" Cold rolled 13.95 [7]

- 2 .5" Dia Pin 1.75" Long 6.29 [8]

- 1 Lower Connecting rod 5/8"x1"x6" 9.91 [9]

- 4 3/4"x1.5' Threaded Rod 14.64 [10]

Baseplate TBD Stuffing Box TBD

- 1 6' Sch 80 Steam Pipe 43.7 [11]

TOTAL 241.51

Alternatively Cast Iron Cylinder Material can be found http://www.mcmaster.com/#8929k18/=gnvh3 for 41.47 per cylinder

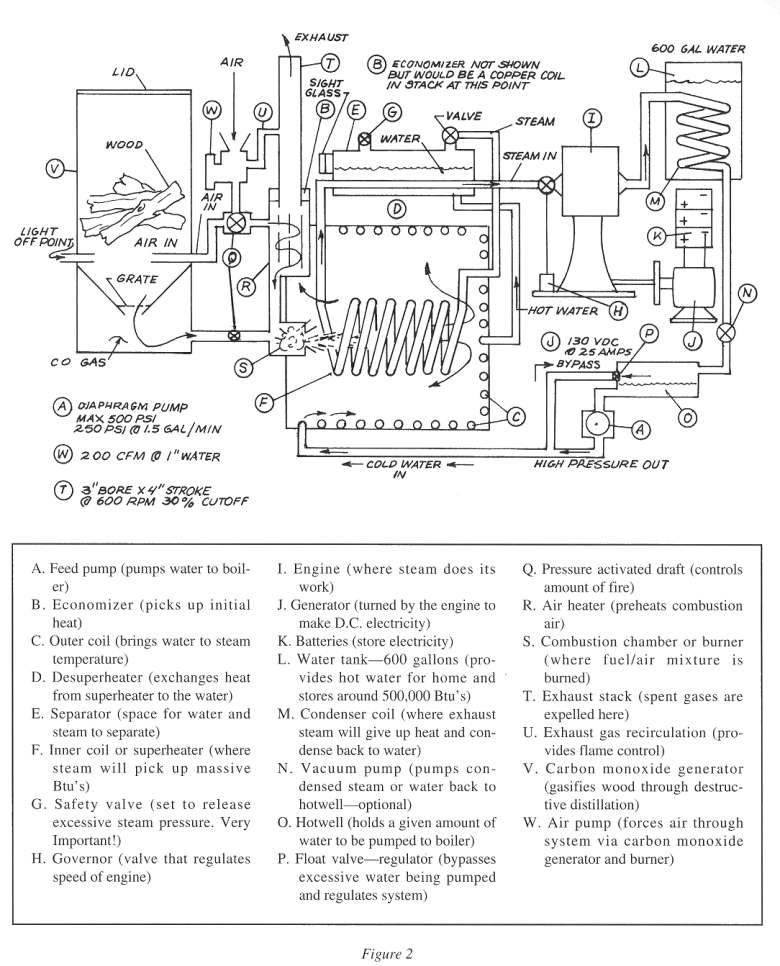

Example of Fully Integrated Steam Energy System

Description of this system by author and excellent background info on homepower steam http://www.fastonline.org/CD3WD_40/JF/JF_OTHER/BIG/Reciprocating%20Steam%20Engine.pdf

Apparently Skip Goebel thinks similar to me about electronically controlled steam engines taken from http://www.mail-archive.com/sustainablelorgbiofuel@sustainablelists.org/msg01818.html

Using Solenoid Valves for Steam Engine in Place of Mechanical Valving

Fwd from [12] - a steam engine producer, which says that 'The biggest news for steam is electric valves' - see Electric Valves for Steam Engine

Electronic Solenoid Valve Info: http://www.gwlisk.com/tech_info.html

Tooling Requirements

Metal Casting

- see Foundry for more details

Waste vegetable oil furnace design http://www.backyardmetalcasting.com/oilburners03.html Foundry.pdf Pattern_Making.pdf

www.budgetcastingsupply.com http://www.metalwebnews.com/howto/furnace/furnace.html www.creativecastingco.com www.host33.com/casting www.backyardmetalcasting.com www.emainc.com/radnor/sand.htm http://oak.cats.ohiou.edu/~dw120996/..._of_metals.htm

Lathe

- Romig bed lathe type - from Multimachine -

- Simple prototype, $486 in materials BOM:

- 2 bearings, $50

- 2 mouning plates, 1/2"x6" angle - $40

- 4 Shaft Collars - $20

- 2" shaft - $20

- DOM tubing, 3", 2" ID - $15

- 8 3/4" bolts for table - $16

- Chuck plate - $40

- Bolts for chuck - $20

- Nuts and bolts for DOM - $5

- XY table - $70 off shelf at Enco - [13]

- Tool post - $10

- table plate - $30

- 2 bags of cement, 80 lb each - $20

- sand, gravel - $10

- TOTAL - $316

- High performance, 2/1000" accuracy with proper technique, stock parts, 1000 lb radial and 200 lb axial load capacity

- Romig bed lathe type - from Multimachine -

Flash Steam Generator

- Coil bending jig - $400

- Stainless steel coil, 150 feet - $200

- Babington fittings and metal - $100

- Dremel tool - $40

- Dremel micro drill press - $40

Electrical Generator

Open Source Steam

Steam power is not taught in general. For mastering this topic, we need a Steam Power Reading List.

- I have some of this material from Tom Kimmel, of Kimmel Steam Power

- Mike Brown offers a reading list here

Steam power engineering is taught by various mechant marine schools and academies around the world. There are hundreds of ships still in service with steam engines and turbines as old as 103 years. I work on one such ship right now. Your design is too complicated: Keep It Simple, See? Research St Mary's Challenger steamship on wiki. The newest engine was made in 1949 and still works fine and is able to compete with brand new diesel tug boats. --Harry Smith

Letters and Communications

Letter to VK Desai of Tinytech Plants -

Dear VK,

Can you share your knowledge of steam power with us?

In order to make our solar turbine a success, we need to build the steam engine at low cost - in house. If I do my own labor, use our machine shop, and use casting in house, then the price for the engine parts should be about $150 for a 3 hp engine. Do you think that is realistic?

Please share with me your basic design. Simple drawings on the back of an envelope would do. I am smart at studying design. Please just give me the essentials and material specifications.

Please respond, or put your notes up directly at:

http://openfarmtech.org/index.php?title=Steam_Engine_Construction_Set

If you have any pictures of steam engines in fabrication, please share.

Sincerely,

Marcin

Response from Mike Brown Steam engines

Nick,

Skip Goebel is in Peru, do you have the DVD he did on building a prototype boiler?

I doubt if your solenoid valve will last six months on a steam engine.

Sorry, we don't get involved in other people's engineering projects (we average two emails like yours a day).

Best wishes, Mike

nick wrote:

Mr. Brown,

I have been working lately on developing a simple horizontal uniflow steam of 3" x3.5" bore and stroke that is controlled by an electronic solenoid valve and a small programmabale logic controller. My full intention is to power this engine with a gasifier monotube style boiler and utilize the exhaust in a 750 gallon thermal storage tank for home heating purposes. In my research in this project I found reference to Skip Goebel's work through your site.

that Skip Goebel may already be building a boiler of similar design, if possible could you give me his contact info? I would also be interested to know if you have given any thought to developing an electronically valved steam engine? I intend to try an asco 1/2" direct acting steam valve that claims to cycle at 800cycles/min for a million plus cycles. I intend to run my engine at 100rpm which in theory may give my controll of the cutoff ratio in increments of .25. This obviously will not be efficient but I want to try the concept first. Perhaps you know more about what this actually would take? In any case I do appreciate your time to read this email and I hope you keep up the good work in small scale steam power development.

Sincerely,

seek out mike brown steam engins on google

Skip Goebel Sensible Steam Peru s.a.c. Lima, Peru Lima 51 996 984 741 US· 559 922 2410 www.sensiblesteamperu.com

To: info@sensiblesteamperu.com Sent: Monday, January 26, 2009 10:22:16 AM Subject: Wood Fired Monotube Boiler

I came across your site in studying the works of Skip Goebel in home powered steam systems. I intend to build a 3kW cogeneration DC system for home and experimental use. All my research leads me to conclude that Mr. Goebel may have pioneered this idea the furthest and I would be interested in purchasing any information that he has made available on the subject.

I'm not unfamilar with steam, I worked 2 years as Mechanical Engineer at a 400MW coal fired power plant, but am now envisioning working on something a little more decentralized. In any case I strongly feel the case for more self sufficient energy systems is here and given the fuel flexibility and reliability of the steam engine I wish to pursue this idea further. My plan is to construct a simple monotube fired 3kW mechanical valve steam engine to charge my DC battery bank and thermal storage tank. After I am comfortable with this design I would like to investigate the potential improvements of using a low cost programable logic controller for boiler control. Additonaly I am looking for a a high speed durable solenoid valve and the right steam valve to investigate the possibility of electronically conrtolling steam into the engine.

Right now I am thinking that I could use a control loop to continously vary the cutoff ratio of the steam engine for my governor. This would optimize efficiency by running with the lowest allowable cutoff ratio. In any case it seems at least feasible to think that in the future steam engines efficiencies can be improved by better steam control which is one more reason that this technology attracts me. So if Sensible Steam has any information avaialable by Skip Goebel on steam engine system construction and experiences with it I would be very eager to hear more about it how to get it.

Sincerely,

Letter to Valve manufacturer;

We do not have any valves capable of handling 600F steam.

Alan Nelson

Fluid Process Control Corporation

Sent: Saturday, January 31, 2009 12:30 PM

To: Alan Nelson

Subject: Atkomatic Solenoid Valve Response Times

Alan, I am looking at your atkomatic line of solenoid valves and would like to know if you offer anything suitable for the a 2-way continous duty pulse cycle valve for saturated steam up to 600 deg. The valve also needs to have a very fast response time of 75ms for open and 75 ms for close. Is there anything in the atkomatic line that might fulfill that response time requirement? If not do you know what other type of valve I might try looking at for that desired response time? Thank you for your time.

Regards,

- Marcin Jakubowski

Links

- Biomass CHP with steam engine - [14]

- 60% vapor cycle efficiency in steam engine power plant? - [[15]]

- $300/hp steam engines in production, Peru - [16]

Steam Engine History:

- http://www.egr.msu.edu/~lira/supp/steam/

- A History of the Growth of the Steam Engine: [17]

- A Catechism of the Steam Engine:[18]

Steam Engine Primers/Groups:

- http://www.pioneer.net/~carlich/RSE/RSEprimer.html

- http://www.the-nerds.org/Steam-101.html

- Promising forum with large library of working steam engine plans: http://www.paddleducks.co.uk/

Engine Plans/Products:

- http://www.pioneer.net/~carlich/RSE/RSEengines.html

- http://www.nearfutures.com/products.htm

- http://www.greensteamengine.com/products.htm

- Triple Expansion Steam Engine Prints: http://www.carferries.com/triple/

- Lindsey Publications:http://www.lindsaybks.com/prod/sub/engines.html

- http://www.grahamind.com/

- http://quasiturbine.promci.qc.ca/Presse/SteamMuller050721.pdf

- These guys claim 30% efficiency on their non compunding multi cylinder steam engine http://www.energiprojekt.com/?product

- 3kW steam engine for $1375: http://www.thesustainablevillage.com/servlet/display/products/byCat/71/441/2557/

- Lots of Plans: http://www.john-tom.com/html/SteamPlans.html

- A nice simple double engine plan: http://openfarmtech.org/images/e/e0/MichelNiggelTwin.pdf

Misc:

- Steam engine from scrap - http://www.btinternet.com/~jhpart/steam2.htm

- Vegetable Oil Based Lubricant:http://www.steamenginelube.com/chelesic.htm

- Homebrew Steam Engine Generator:http://www.otherpower.com/steamengine.shtml

- Steam Engine Manuf. Links: http://cedesign.net/steam/steam-links1.htm

- Oil Free Steam Engine Design for Vehicles: http://six6.region-stuttgart.de/sixcms/media.php/773/23_Platell_P.pdf

- Flash Steam Engine, Could this be advantageous http://www.huzar-power.com/steam_engines/revival/flash_steam.htm

Nick R. says, what are the limits to lathe boring diameters in cast iron? This [19] method of construction looks simple and attractive if it could be scaled up enough?