Universal Rotor Intro

Main > Food and Agriculture > Farm equipment > LifeTrac

| Universal Rotor | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

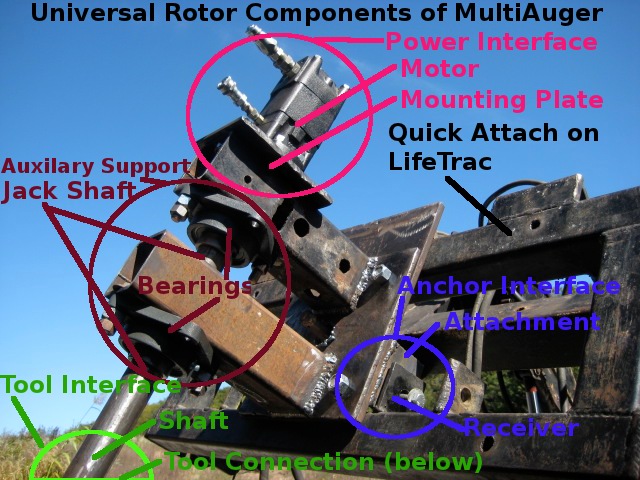

The Universal Rotor is a structural assembly that holds a shaft with bearings, which is attached to the LifeTrac quick attach plate, or which can be detached and used in other applications. The hydraulic motor is interchangeable, and so far, a 32 cu in and a 6 cu in motors have been used. Motors at Factor e Farm have a quick mounting plate with 2 3/4" bolts for hold-down.

The assembly can be mounted either horizontally or vertically by bolting to a back plate accordingly.

This is a Universal Rotor which to date has been used as the basis of a trimmer, tree planting auger, lathe, drill press, soil line cutting rotor, and honey extractor.

Future work on this involves improved structural integrity, better mounting for LifeTrac, and improved interchangeability of motors.

CAD Drawings

I have put together a preliminary CAD drawing in BRL-CAD. The file is based on the picture above and the posted dimensions of the LifeTrac front plate specifications. Some of the dimensions I did not have data for so I just estimated from the scale in the picture. What I should be able to do is post a sketch of all the pieces made from the CAD file and then we can either have someone on the farm measure and post the corresponding dimensions for the files from the existing prototype, or we can just have a discussion on the wiki here about what the various measurements should be on future models, regardless of the dimensions of the prototype now in existence.

For now I am just posting a rendering of the CAD file, I can post the .g file once I get the exact dimensions for it.

Note: To the people at Factor e Farm, if one of you could print the sketch of this machine and write on measurements for all the relevant dimensions and then re-scan the page with that information, I can update the model so it matches the as-built prototype you have at the farm. This could then serve as the basis for further refinements for the next prototype.

Andrew, sign up at http://openpario.mime.oregonstate.edu/projects/unirotor/