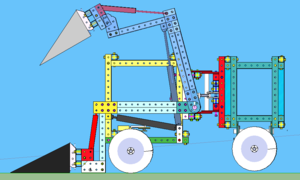

The Spark Build

Jump to navigation

Jump to search

Quality Control

- Download File:Cab and Loader Arms 12pm Jul 11.skp

- Loader forearm stability

- Force on arm lift cylinder mounting

- 9 degree cylinder angle means 9400 lbs lift force

- Foot pedal detail

- Valve 1 mounting plate detail

- Valve 2 mounting plate detail

- Foot pedal detail

- Pin tight with lever

- Seat mounting

- Wheel shaft procedure

- Loader down pressure

- Bolts clearing everywhere

- Bolting feasibility everywhere

- Build order correct for each module

- Build order correct for complete assembly

- QA plate spacing

- Reverse the curling cylinders

- Part count minimization - cylinder mount

- Part count minimization - rear pivot connection

- Part count minimization - front pivot connection

Parts

First Choice

- 3 Spool, 25 gpm Motor Valve for Wheels, auxiliary implements, and turning - [1]. Needs Power Beyond Sleeve - [2]

- 25 GPM Joystick valve - [3]

- [4] hoses - [4]

- [2] hoses - [5]