Proposed GVCS

Overview

The GVCS list is currently locked at 50. Though additions are welcomed to be researched for later integration (after completion of the GVCS 1.0).

See Adding a GVCS Tool for more information.

Proposed tools

- Loader - an attachment for the LifeTrac tractor

- Village-scale washing machine - powered by the universal rotor

- Reversible heat pump - for controlling the temperature of homes and greenhouses, refrigerating food and medicine, harnessing solar and geothermal heat

- Stirling engine - transforms heat into mechanical energy

- Spectrometer and computer oscilloscope - adding these to the GVCS would form a complete Fab Lab. Most of the work will be done by other open-source groups.

- Juice Press - A juice press powered by the Power Cube.

- Log Splitter - A log splitter powered by the Power Cube.

- a solar thermal collector; based on the Zaragoza SHWH with modifications

- a large biodiesel reactor

- a large still (for production of ethanol)

- a solar still either similar to this or based on the Zonnewater B.V. stills. Both designs use an electrical heater and the second design uses a PV panel. This means that besides better efficiency (as heating/cooling is seperated), the design can also be used when the sun doesn't shine by using electrical power from other renewable energy sources.

- a large biogas production plant

- production plants of other emissionless fuels, for example biobutanol (see appropedia link 1 and appropedia link 2)

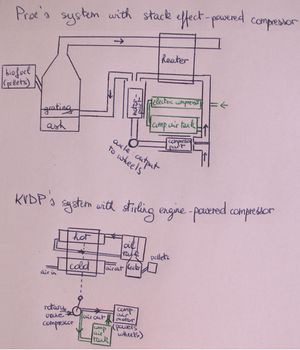

- a compressed air energy storage system; a small scale system like this doesn't exist yet, should be similar to this design

- For the GVCS car, see the image at the right and the description. I think that experience gained with this idea would be useful for the compressed air energy storage system mentioned above. The file description was previously at appropedia.

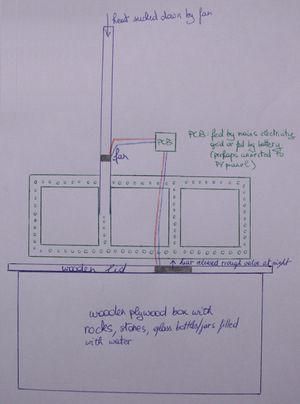

- The Strawbridge heat sink can be added (I modified this from Strawbridge's original design). See image on the right. The file description was previously at appropedia (http://www.appropedia.org/Growing_under_cover )

- For the 3D printer, I think you best swap the RepRap design with the ORDBot design (http://www.appropedia.org/Open_source_3-D_printers#List_of_open_design_3-D_printers ) It's stronger and I think with some thinkering you could print more materials (perhaps including metal)

- Besides the seeder, perhaps include a wheeled auger (similar to http://users.skynet.be/sb021277/Pages/Nederlands/Pflanzfuchs/PF.html ) That's a cheap thing to allow 2 people to seed quickly, and also allows other uses (ie making holes for construction, ...)

- swap the spader with a regular rototiller but just make that rototiller easier to fabricate/cheaper. You could also make a version adapted for use on the traction engine design I made (a light vehicle such as this requires less fuel to operate the implement). A spader

isn't any better (actually worse in my view as the soil isn't cut up as much. No-till is all the rage these days (see http://www.betuco.be/CA/No-tillage%20Farming%20for%20Sustainable%20Development.pdf ), but really it isn't absolutely necessairy, rather we just need equipment that is much more precise, for example rototilling only upto the depth required for planting (and not more). So make the depth settable. Even better would be to only cut up the soil exactly where you plant, so leaving the interrow-sections unaffected, however that's difficult to accomplish.

- you also seem to not have many specialized agricultural tools, for example for harvesting fruit from orchards. For harvesting olives/nuts from trees, shakers/vibrators are for example used that clamp on the tree and shake off the olives/nuts. For collecting the fallen off

produce, tarps on rolls are sometimes used (tarps being rolled up automatically, sliding the produce off into a bin). An other approach is by using disc brushes (round rotating brushes as used in municipal services to clean up litter from streets)