Greg Log

Jump to navigation

Jump to search

2014 August 27 Wednesday

- Moved microhouse lumber from south of new workshop to protected shelter east of old workshop

- Installed lock hardware and vent pipe cap on Composting Toilet

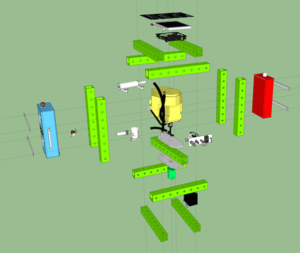

- worked on exploded parts diagram for Structural Powercube

2014 August 26 Tuesday

- built shelves for my bedroom out of scrap materials

- swarmed on workshop cleanup (moved Microhouse 3 modules into old workshop, moved lumber out of the way, etc.)

- updated Composting Toilet CAD file

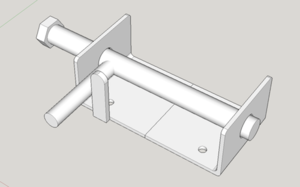

- led evening walkthrough/tutorial on Sketchup (walked through CAD drawing of barrel bolt latch design for toilet on the big screen)

2014 August 25 Monday

- completed fabrication of latch hardware for composting toilet

- worked on fabricating earth anchors to stake down the composting toilet (against possible wind intrusion)

- cleaned and dried tents left out in the rain & mud after microhouse workshop

2014 August 23 Saturday

- Deep cleaned Hablab kitchen, including dealing with fermented watermelon

- Vacuumed Hablab living room

2014 August 22 Friday

- Finished and installed doors, hinges, and door handles on composting toilet

- Cleaned up remaining tools and scrap materials at composting toilet site

- Began fabrication/design for barrel bolt latches for doors

- Finished fabricating vent pipe cap

2014 August 21 Thursday

- Collected materials on hand for designing and building doors for composting toilet (used scrap 1x lumber and unused 3/4" carsiding)

- Began layout and construction of doors

2014 August 20 Wednesday

- Installed handrails on composting toilet

- Patched a few stray roof holes

- Began fabrication of vent pipe cap

2014 August 19 Tuesday

- Assisted with Microhouse 3 documentation

- Installed stair stringers and treads.

- Installed vent pipe. 3.5" hole saw from Sutherland's broke within first 30 seconds of use (either mandrel or saw threads stripped immediately, allowing saw to spin freely instead of cut, and preventing removal/replacement of saw on mandrel). Worked around by firmly tightening a 5/8" nut on mandrel threads.

2014 August 18 Monday

- Worked on Microhouse 3 documentation, including updating Sketchup files

- Designed & laid out stairs for composting toilet. Revised design to accommodate existing mature tree on site (shortened tread length and steepened stair angle to ~42°)

[File:stair_layout.png|300px]

- Cut stringers for toilet stairs

2014 August 16 Saturday

- Purchased materials for composting toilet at Sutherland's: 3.5" hole saw and pipe boot for vent pipe, treated 2x12's for stair stringers

2014 August 7 thru 12

- Microshouse 3 workshop

- Supervised workshop during construction of carpentry modules

- Assisted with CAD questions and Dozuki documentation

- Laid bricks and installed window modules at site

2014 July 28 Monday

- Continued carpentry for formwork with Arif. Completed 2x4 frames

2014 July 25 Friday

- Continued carpentry for formwork with Victor. Began assembly of 2x4 frames

2014 July 24 Thursday

- Started carpentry for formwork: worked with Victor to setup the space, bring materials, get power to the site, and begin planning.

2014 July 23 Wednesday

- Returned to Factor-e Farm

- Drove Catarina to St. Joe on a hunt for a new laptop.

2014 June 16 Monday thru June 20 Friday

- Wisconsin for CEB Press Workshop, and Midwest Renewable Energy Fair. Returned to Boston June 20.

2014 June 13 Friday

- Continued work on 3D printers, CEB Press documentation, prep work for Wisconsin CEB Press workshop.

2014 June 12 Thursday

- Worked on master SKP file for CEB Press - working with layers, transparencies, etc. for creating functional schematic

- made 2 simple flat boxes with honeycomb - 1 stop ⅔ through, the other let it complete

- changed nozzle size setting in Slic3r to 0.5mm (and also increased layer hight to 0.5mm) - seems to work better! Seems that AO-100 has 0.5mm nozzle after all.

- worked on making fresher STL file for clampshells from SKP

- attempted ¼ size print - failed catastrophically - drifted in Y-axis, etc. Diagnosis: Z-stop too low, so Z-home presses nozzle too tightly agains the bed. Raised z-stop, and print was much better!

2014 June 11 Wednesday

- Presented 3D printing progress, challenges, learnings, including examination of 1st attempt at printing clampshell

- Reviewed CEB Press Drawer Module assembly instructions in morning meeting

- Researched converting STEP files to SKP, and added to STEP to Sketchup wiki page

- Pulled clampshell file from CEB .SKP file, scaled to 1/4 size and exported to STL. Converted to .gcode using Slic3r at 0.75 infill. Print started OK, but about 20% of the way through, it was thrown off of the Y-axis by about 0.5" (20% of the 2.5" length). My working hypothesis is that working in other programs on my computer during the printing caused a serial error. To remedy this (and sleep/screensaver interruptions) I'm going to look into printing from Micro SD Card.

- Very good Micro SD Card printing instructions at the LulzBot site. Successfully test printed bed level check from Micro SD Card.

- Also troubleshot blobby / pad printing on initial error. It was due to too much pressure between printhead and bed - see pictures below. I fixed it by raising the Z-endstop limit screw (see picture) and re-leveling print bed.

- Experimented with layer depth & infill. Found that 0.35 mm layer depth (equal to the nozzle size) works much better than the previous setting (which was 0.2 mm). Also honeycomb infill with a density of 0.3 works quite well for sturdy, relatively quick prints

- Began overnight print of full-size Female Clampshell with 0.3 density honeycomb infill. Fingers crossed!

2014 June 10 Tuesday

- Presented 3D printing results at morning meeting

- Began work on CEB Press .SKP

- Worked on Presentation on 3D Printing - [1]

- Started rudimentary first print of File:01-222-00-2.STL for overnight printing

2014 June 9 Monday

- First day of work. Attended orientation, began worklog, hit the ground running.

- Worked on CEB Press Drawer Module documentation

- Oriented self to basic CEB Press operation, brick compression process

- Swarmed on getting 3D printers up and running - worked on HYDRA Lulzbot. Got it connected to computer, leveled printbed pretty well. Ran into troubles with .gcode files - printer randomly stops prematurely, causing print to fail. Looks like Colten had similar troubles: Colten Jackson Log

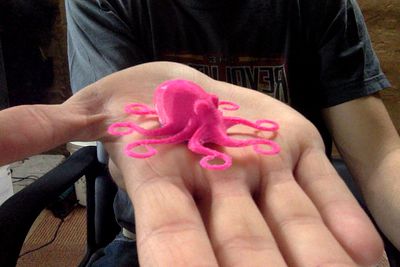

- Successfully printed an Octopus on the TAZ out of pink PLA plastic:

2014 June 8 Sunday

Arrived at Factor-e Farm. Got settled in, setup living situation, met team.