Aerial Ropeways

Simple, inexpensive yet powerful technology. One of the most energy-efficient forms of transporting goods and people. Relatively easy and quick to set up, operate and take down again. The most common materials used for constructing ropeways were first wood/fiber and then steel/steel ropes. The introduction of steel ropes and electric motors was a major efficiency boost, so these should probably be the preferred option.

Gravity-powered ropeway

In mountainous regions, a ropeway may be powered by gravity alone (see links below, Nepal). This opens up possibilities for high-volume, low-cost trade between high-altitude mountain communities and low-altitude communities. Costs are fixed, and are dicated only by the ropeway infrastructure. There are no additional costs, such as energy costs. A mountain community may deliver construction materials (e.g. stones, bricks and sand) or minerals. A lower-altitude region may deliver biomass/biofuels.

Open source ropeway hardware for large-scale biochar transport

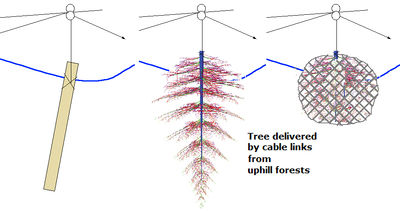

Biochar is becoming increasingly recognized as an important soil amendment and strategy to reverse climate change. Some regions of the world, such as the semi-arid drylands, have little capacity for producing biomass and biochar. Other regions, such as forests, produce an abundance of biomass but it is often at risk of wildfires, releasing gigatons of carbon dioxide into the atmosphere as part of the normal carbon cycle. Therefore, the production of biochar in forests has been proposed, followed by transport to nearby biomass-poor regions. If done by ground transport (trucks, rail), this would be prohibitively expensive and would make no sense from an emissions point of view.

Aerial ropeways may change that equation, as they have many qualities needed to transport large amounts of biochar energy-efficiently and inexpensively. The energy released from biochar production (heat) can drive a heat engine that powers the ropeway. Even topsoil could be transported in this way, for rapid regeneration of degraded soils.

Some open source hardware development is needed, and may include:

- very large bins of sheet metal with steel supports (biochar is light-weight and bulky); bins are designed to prevent carbon dust that might explode (need to be covered/closed)

- poles that can be constructed of steel (in the drylands) or wood (in forests); design for rapid take-down and re-assembly elsewhere

- steel rope with standardized diameter to be used everywhere

- standardized wheels (possibly sand-cast or CNC-machined ?), i.e. a shape that works well with the size of steel rope chosen

- development of social and financial structures to facilitate these ropeways (i.e. to address NIMBYism by financially including landholders who provide the land)

External Links

- Low-tech Magazine: "Aerial ropeways: automatic cargo transport for a bargain"

- Practical Action: "Technical Information Online Ropeways - Aerial Ropeways in Nepal"

- Appropedia: Aerial Ropeways in Nepal

- Appropedia: Ropeway in the Himalayas