Biochar

According to the International Biochar Initiative: "Biochar is a fine-grained charcoal high in organic carbon and largely resistant to decomposition. It is produced from pyrolysis of plant and waste feedstocks. As a soil amendment, biochar creates a recalcitrant soil carbon pool that is carbon-negative, serving as a net withdrawal of atmospheric carbon dioxide stored in highly recalcitrant soil carbon stocks. The enhanced nutrient retention capacity of biochar-amended soil not only reduces the total fertilizer requirements but also the climate and environmental impact of croplands.

Char-amended soils have shown 50 - 80 percent reductions in nitrous oxide emissions and reduced runoff of phosphorus into surface waters and leaching of nitrogen into groundwater. As a soil amendment, biochar significantly increases the efficiency of and reduces the need for traditional chemical fertilizers, while greatly enhancing crop yields. Renewable oils and gases co-produced in the pyrolysis process can be used as fuel or fuel feedstocks. Biochar thus offers promise for its soil productivity and climate benefits."''

Some of the world's most productive soils (e.g. Canadian prairies, Russian Chernozem / or "black earth") are very rich in organic carbon, probably pyrogenic in origin and originating from prairie or forest fires. The black carbon is often thousands of years old, demonstrating its stability in soil. For more extensive background on Biochar, please look up the Wikipedia entry, read File:SCM-30.pdf or consult the website of the International Biochar Initiative.

There is some evidence that high-quality biochar requires low operating pressures, to allow volatiles to escape during the reaction. Therefore, the attempt to use pyrolysis gases and even just a retort may lead to inferior char. The Earth Pit Kiln and the Kon-Tiki Kiln operate at low (i.e. atmospheric) pressure.

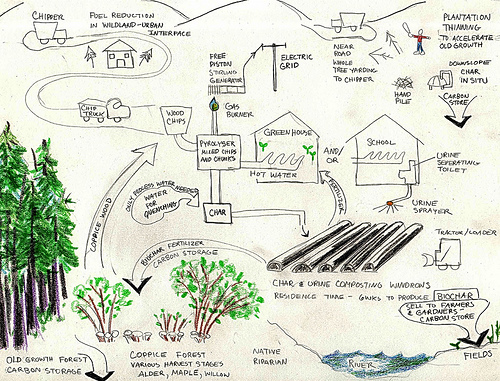

Product ecology and The Biochar Economy

- Inexpensive soil amelioration for degraded land

- Increased biomass productivity

- Reduced need for fertilizer input (e.g. manure).

- biochar added to biogas fermenter may improve methane production (see reference)

- Composting: combine biochar with Vermiculture for superb fertilizer, or add to compost heap to speed up composting (works via enhanced microbial activity);

- biochar to neutralize smell in composting, e.g. with composting toilet

- biochar-producing tractor: the Charvester

- Bio-oil and tars are also by-products of pyrolysis, can be turned into Bio-Petrochemicals , or burned / Gassified in a Heavy Oil Burner

- Use Lifetrac (and soil pulverizer) to mix char into soil, till

- Biochar for sale as a source of income, especially when "aged" (i.e. composted, vermicomposted)

- biomass waste for energy generation

- Pyrolysis gas can be used for energy (i.e. compressed fuel gas) and as a heat source (e.g. for heating greenhouses). As a source of hydrogen, CO and small amounts of methane, pyrolysis gas may be useful for various processes

- Charcoal is already needed for other purposes, e.g. metal smelting

- Charcoal as filter: can be used for water purification and filtration, later become biochar; can be used to filter pyrolysis gas itself (also see: biofilter)

- See Also: Kon-Tiki Kiln and Earth Pit Kiln

- "Biochar as a feed additive" (for horses, cows, pigs, chicken, sheep, goats, dogs and cats)

Potential Co-Products

- The standard co-product with biochar is heat. Use for space heating (greenhouses, hot water, steam for cleaning or steam engine)

- heat for: fired ceramics, tiles, terracotta, glassmaking, ...

- The CO2-rich off-gas may also potentially be used as a plant stimulant, if the combustion is very clean (e.g. with Kon-Tiki Kiln). Some plants are more sensitive to combustion-derived impurities than others. The exhaust gas can be purified with a soil biofilter.

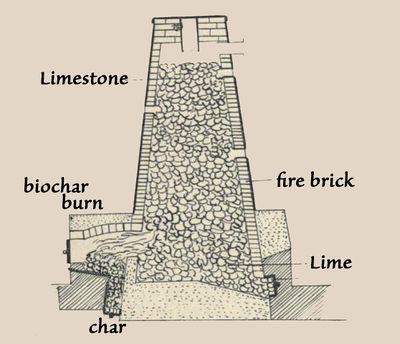

- Biochar-Lime Co-production System

- Biochar/Brick Co-production System

- Pyrolysis Oil

- Bone Char can be made in the same process as biochar

- internal combustion engine (requires very clean wood gas, with filters and ad-hoc fractional distillation system) - see video by MrTeslonian

Subsoil Biochar

Almost the entire biochar literature involves the application to topsoil or pots. Almost no research has been done investigating the application to subsoil, despite the well-known interconnectedness of soil/subsoil biology, water and nutrient flows, and the deep extension of tree roots into subsoil. The very limited literature that exists so far may indicate positive effects on plant growth (see: link and link).

The following conclusions were drawn from a subsoil research project at the Technical University of Denmark led by investigator Henrik Hauggaard-Nielsen:

- Biochar of up to 2% increases root growth, 4% decreases it

- Increased water retention

- 1% biochar is most beneficial for root growth and grain yields

- subsoil pH goes way up with increasing biochar concentration: pH 7 at 1%, pH 8.3 at 2%, pH 9.3 at 4%.

The perspectives include: subsoil transformation of low-productivity soils, new crop choices, cash crops versus pastures. It is unclear how to incorporate biochar into subsoil (inject?, dig?) and whether this is feasible for the farmer (what are the costs of application?). The level of yield increases and improved nitrogen retention is unclear. If proven, subsoil biochar would create a major need for open source hardware development in this area: subsoiler, pulverizer, injector, etc.

Discussion

Could someone suggest a design for a simple flexi-pyrolysis unit that makes both charcoal and syngas ?

- Yes, the Biochar Experimenter's Kit -- it's open source.

Some discussion of Biochar manufacture and use (including reference to mobile pyrolyser developed at VA Tech) on this blog posting: Turning Points - Biochar: Make It or Buy It?. Two earlier posts on biochar from Turning Points blog.

Dan Schellenberg's Biocharred Soil Sample

- When large chunks of wood are used as feedstock, they may need to be crushed before use (beware: coal dust explosion !). See Biochar Crusher for more about this.

Field Trial Results by BlueLeaf / Dynamotive (March 2011)

"Biochar Commercial Agriculture Field Trial in Québec, Canada – Year Three: Effects of Biochar on Forage Plant Biomass Quantity, Quality and Milk Production" (Full details of the report available here, internal copy)

These are the first biochar field trials undertaken in northerly latitudes (45° north).

Key results include:

- Continued greater biomass growth for the third consecutive year in biochar-amended soils

- Nutritional quality of plants grown in biochar-amended soil is verified by near infrared spectroscopy for first time

- Plant nutrient uptake efficiency and plant nutritional quality is greater in plants grown in biochar-amended soil

- This greater plant nutritional value leads to greater milk production from these forage plants

- In addition to the greater nutritional value of plants grown in biochar-amended soil as well as greater milk production, environmental advantages are anticipated through reduced leaching and reduced greenhouse gas emissions

- These results were achieved with a relatively low biochar application rate (3.9 t/ha), in a northerly climate (N45˚), on normal agricultural soils.

The results of these trials reinforce other research pointing to potentially important advantages for the use of biochar as an agricultural soil amendment, both for economic and environmental reasons.

Data of effect of biochar on yield

- The trial cited above by BlueLeaf found modest increases in yield. Dry matter yields were increased by only 2.7% after three years applying biochar. However, the plants grown (forage for ruminants) were more nutritious on the biochar-treated fields, so researchers project a 19.7% increase in the yield of milk from animals grazing there.

- This trial found that biochar alone had no effect on yields, but when applied along with N fertilizer, there was a synergistic effect. Biochar alone gave 0% increase, N fertilizer alone gave 95% increase, while biochar and N fertilizer increased yield 266%

- This trial on maize yields in Ghana found a 91% increase in yield.

- This study found a 42% increase in yield when 10 tonnes/hectare were applied and a 96% increase at 50t/ha (that's 5kg/m2 for those of us with less land)

- This study found no increase the first year, 28% the next year, 30% the following year, and 140% the year after that. Application was 20t/ha, or 2kg/m2

- This found a decrease in yield, even though the soil was poor in carbon to begin with.

The bottom line is that the biochar will initially take nitrogen out of the soil, potentially reducing yields until it is saturated. This can be avoided by adding nitrogen to the biochar before or during incorporation into the soil.

Videos

- BadgerChar batch farm scale char maker - [1]

"55 Uses of Biochar"

This is from an article by Ithaka Institute. The 55 proposed uses are:

1. Silage agent 2. Feed additive / supplement 3. Litter additive 4. Slurry treatment 5. Manure composting 6. Water treatment in fish farming 7. Carbon fertiliser 8. Compost 9. Substitute for peat in potting soil 10. Plant protection 11. Compensatory fertiliser for trace elements 12. Insulatio (building sector) 13. Air decontamination 14. Decontamination of earth foundations 15. Humidity regulation 16. Protection against electromagnetic radiation (“electrosmog”) 17. Soil additive for soil remediation [for use in particular on former mine-works, military bases and landfill sites.] 18. Soil substrates [highly adsorbing, plantable soil substrates for use in cleaning waste water; in particular urban waste water contaminated by heavy metals] 19. A barrier preventing pesticides getting into surface water [Sides of field and ponds can be equipped with 30-50 cm deep barriers made of biochar for filtering out pesticides.] 20. Treating pond and lake water [Biochar is good for adsorbing pesticides and fertilisers, as well as for improving water aeration.] 21. Biomass additive 22. Biogas slurry treatment 23. Active carbon filter 24. Pre-rinsing additive 25. Soil substrate for organic plant beds 26. Composting toilets 27. Micro-filters (treatment of drinking water) 28. Macro-filters in developing countries (treatment of drinking water) Exhaust filters (29. Controlling emissions, 30. Room air filters) Industrial materials (31. carbon fibres, 32. plastics) Electronics (33. semiconductors, 34. batteries) Metallurgy (35. metal reduction) Cosmetics (36. soaps, 37. skin-cream, 38. therapeutic bath additives) Paints and colouring (39. food colorants, 40. industrial paints) Energy production (41. pellets, 42. substitute for lignite) Medicines (43. detoxification, 44. carrier for active pharmaceutical ingredients) Textiles (45. Fabric additive for functional underwear, 46. Thermal insulation for functional clothing, 47. Deodorant for shoe soles) 48. Filling for mattresses 49. filling for pillows 50. Shield against electromagnetic radiation (to be continued to 55...)

Internal Links

- User:Gabrielle LeBlanc

- Biomass with CCS

- Charcoal Workflow

- Geoengineering Watch (against all this-ish?)

- Tera Preta (the "gold standard" for soil, not 100% on how it was developed, but mainly Slash and Char , thus Biochar)

External Links

- The Wikipedia Page on Biochar

- Need to move all the kiln stuff to appropriate pages later

- An article on a Retort Style Charcoal Kiln and how to build it

- An article titled ""Gardening with Biochar FAQ"" (Mainly about small-scale gardening with biochar, seems to be an excellent resource.)

- A BioEnergy Lists Page titled " Terra Preta (Biochar) "

- A link to the International Biochar Initiative (IBI) main website

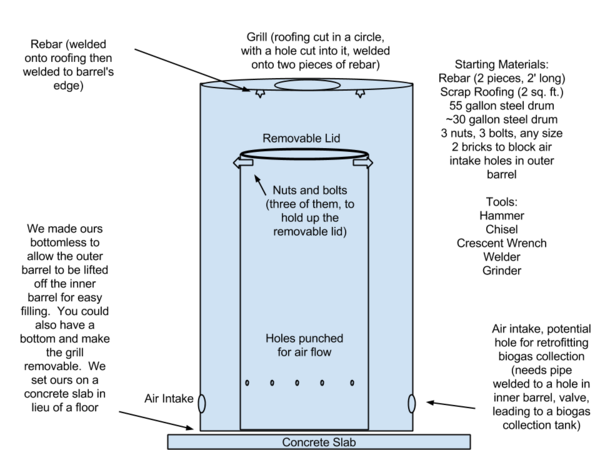

- Folke Günther's "the simplest of the simple" two-barrel charcoal retort

- Poster: OpenChar Initiative (internal copy on this wiki) ( where?, find this later )

- An article on Biochar (internal copy on this wiki) ( where?, find this later )

- An article by Ithika Journal titled "Treating liquid manure with biochar"

- An article by Ithika Journal titled "Biochar in poultry farming"

- An article by Ithika Journal titled "55 Uses of Biochar"

- A Video by the Youtube Channel "Cody's Lab" titled "Effect of Biochar Particle Size On Plant Growth Part 1"

- Need to find "proper studies" on this as well, as it is an important data point