Precious Plastic Extruder

Jump to navigation

Jump to search

Working Doc

![]() Hint: This work builds upond the precious work of Precious Plastic. We are indebted here to Dave Hakkens. See https://preciousplastic.com/en/videos/download.html

Hint: This work builds upond the precious work of Precious Plastic. We are indebted here to Dave Hakkens. See https://preciousplastic.com/en/videos/download.html

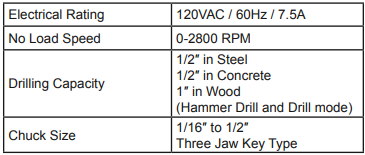

BOM

- Wood bit - 1" - [1]. 7/16" shank, as in 1/2" version. Local - [2]

- Pipe flange - Menards $5 - [3]

- Pipe flange - pack of 10 - Amazon - $4 ea - [4]

- 1" pipe -

OSE Version Design Rationale

- Slow auger version powered by a Nema 17 with large auger.

- Vertical hang to reduce auger power requirement

- Remove flow control screw and rely on temperature and auger speed instead. PP version doesn't have speed control on motor, so motor control produces additional control required here

Calculations

- We want low speed equivalent to a strong corded drill such as [5].

- Torque Calculator shows this drill has only about 30 in-lb torque

- This is more like it - [6] - 0-600 RPM, same power - means - 140 in-lb.

- PP shredder is 1770 in lb - 10x stronger - Precious_Plastic_Shredder#Torque_and_RPM

- We have experience with Lyman filament maker, 50W, 140 in lb:

- About 140 in lb for motor above. This should be plenty for an extruder application.

- If we take a 1A, 12V motor - Nema 17 -

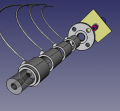

CAD - OSE Version

- This is the OSE version remake. See https://github.com/OpenSourceEcology/Extruder

Filament Extruder

Overall Build - FreeCAD -File:Filamenter overall.fcstd

Overall Build - FreeCAD -File:Filamenter motor.fcstd

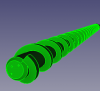

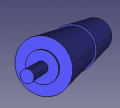

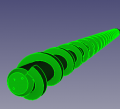

Auger - FreeCAD -File:Filamenter auger.fcstd

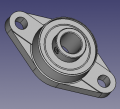

Auger - FreeCAD -File:Filamenter bearing.fcstd

Auger - FreeCAD -File:Filamenter flowcontrol.fcstd

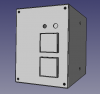

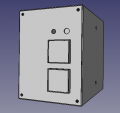

Extruder Controller

File:Filementer controller.png

Overall Build - FreeCAD -File:Filamenter controller.fcstd

BOM Candidates

- Insulator brick - [7]

- Carbon fiber welding blanket insulation - [8]

- Small high torque hydraulic motor - [9] $50

- Type K Thermocouple - [10] - $7

- SSR - [11] - $7

- 1" flange - $4 on amazon - [12] or $5 menards - [13]

- PID Controller - $23 - [14]

- PID with SSR + thermocouple - $14 - [15] - got 3.

- [3] band heaters - 35x45 mm - $4 + SH - [16]

- [1] band heater - 1.75" for next coupler

- 1-3/4" coupler - [17]

- 1.75" heater - [18]

Notes

- 1.75" is 45 mm

- 35 mm is 1.38 in

- 40 mm is 1.57 inches

- OD of pipe union

- 1.25" and 1.75" nozzle heaters are available easily - [19]