UELVE MBC

Jump to navigation

Jump to search

UELVEs MBC

Intended as a lightweight proof of concept for further development of additional larger (and smaller) hybrid and tribrid electric vehicles.

Acronym decoding:

- UELVEs: Ultra-Efficient Libre Vehicles for Everyone.

- MBC: the Embassy, or the "MythBusters Car" (get it?), in honour of their discovery that a golf-ball texture on a car bodypanels significantly improves fuel economy. https://www.youtube.com/watch?v=VUiGhyHC-1A

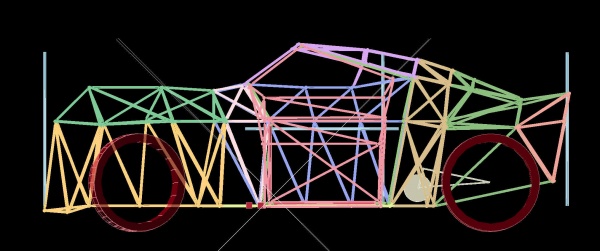

Concept

Specifications

- 4 wheels using mountain bike 19in rims and 2.75/19 motorcycle tires (26in outer diameter)

- 100kg weight (full, complete vehicle)

- 2 occupants

- Twin 3-5kW Axial Flux BLDC chain-driven motors (no gearbox needed)

- 1.1 x 1.5 x 3.4 metre dimensions with an "airbox" down the centre

- Only a 1.1 m^2 front surface area (due to the "air tunnel")

- 0-60mph in under four seconds (Sur-Ron "3" kW Motors can be pushed to 13kW for short durations, and there's two of them)

- over 200mpg at 55mph due to low weight, low rolling resistance, reduced surface area and low drag coefficient.

- capable of driving up a 50% gradient at around 25mph with 2 occupants.

Design Concept

- Use downhill mountain-bike parts that have been proven to be light, strong and effective up to a 50kg weight with an 80kg load, thanks to the Sur-Ron Electric Bike.

- Use twin Sur-Ron direct-drive 3-5kW Axial Flux electric motors

- Use twin ASI BAC4000 BLDC Controllers (or VESC Vedder BLDC Controllers http://vedder.se/2015/01/vesc-open-source-esc/)

- Outer skin using the GABoats technique (Geodesic Aerolite Boats) - http://gaboats.com

- Inner frame using 3D-printed fibre-reinforced "nodes" connecting continuous-fibre-reinforced pipes on a Fibre_Reinforced_Pipe_3D_Printer or getting carbon-fibre, hemp-reinforced tubes (or even Bamboo), based on the Divergent 3D "Blade" car manufacturing concept https://www.youtube.com/watch?v=vPv7PwS50OE

- Epoxy-soaked cloth "wrapping" carried out on joints, if necessary, using the Calfee Design Bamboo bike technique. https://calfeedesign.com/what-is-in-calfee-diy-kits/

- Swappable Modular batteries using the Open_Source_Battery_Pack

Source Code

- git clone http://lkcl.net/vehicle_3d/.git

TODO

this page.

Material Strength Test

- two M10 1.5mm pitch bolts (or close: 3/8 with 1/16in pitch)

- a 30 x 30 x 30mm cube made of fibre reinforced plastic with a smooth cylinder hole down the middle about 7 or 7.5mm diameter

- print that using 100% infill, fibre reinforced plastic, with a minimum 0.8mm nozzle, preferably 1.2mm, with the hole pointing UPRIGHT.

- screw the two M10 bolts in, using the thread to "tap" the holes, making them meet in the middle

- hang it from a bench by 1 bolt and keep putting weights on it until it breaks.

i need to know, how much weight it took. it might be a lot, before the cube breaks or the threads strip.

the next test is printing it where the hole is horizontal.

the "more advanced" version of that is for the hole to be at 45 degrees through the cube, i.e to test the effect of diagonal layers.

See Also

Useful Links

- Simple Vehicle Simulator including gears, gear-changes, wind-resistance, rolling-resistance, gradients etc. http://lkcl.net/ev/vehicle_simulator/output/Simulator.html