April 2011 Production Run BOM

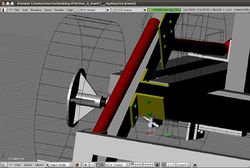

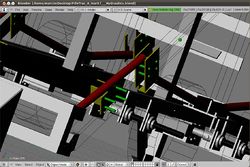

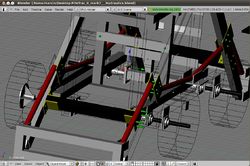

Download open source tractor 3D source code

Cut List: Tractor

Square tube:

- 4 × 76"×4"×4" tubes for base (shortened by 16")

- 3 × 5'×4"×4" under base tubes.

- 2 × 52"×4"×4" vertical chassis centre tubes.

- 2 × 55"×4"×4" vertical chassis tubes for front corners.

- 2 × 59"×4"×4" vertical chassis tubes for rear corners (PC mounting area).

- 2 × 68"×4"×4" top chassis tubes.

- 3 × 44"×4"×4" top chassis tubes.

Rounds:

- [4] 28" × 1-7/8" axle shafts (22" before; turn gussets around for easy wheel takeoff)

- [1] 56"×1-7/8" loader shaft.

Rectangle:

- [2] 100"×6"×3" 3/8" tubes for front loader arms.

- [4] 6"×4" 1/2" angle-iron to attach re-enforcing tunes to Loader arms.

- [4] 4-1/2" 1-7/8" DOM to mount shafts through the frame.

- [4] 3-1/2" 1-7/8" DOM to mount loader shafts to loader arms.

- [8] thrust bearings - in the form of large washers with 1-7/8" hole to go between frame-shaft-DOM-mounts and loader arm mounts.

- [4] 6" bushings/DOM to weld in gussets and wheel mounts.

Plate:

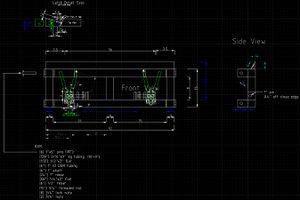

- [12] 10"×8"×0.5" steel plates to mount flange bearings and hydraulic motors to frame.

- [4] 6"×8"×1/2" QA-plate to mount motors to QA-motor plate.

- [2] 6?"×12"×1/2" plate to mount H-cylinders to frame base.

- [4] 6"×4"×1/2" plate to weld to H-cylinder base plates.

- [8] 1" diameter-hole nuts to weld into above plates.

- [1] 1/4" 4or5"×36" plate to mount Valves to.

- [4] 8"×12"×3/8" plate to connect Front H-cylinders to loader-arms.

- [4] 12×10×1/2" plates to make wheel mounts.

- [8] 4"×4"×1/2" plate cut diagonally to make [16] gussets.

- [4] × 32"diameter × 9" wheels.

- [16] thrust bearings - in the form of large washers with 1-7/8" hole - torch these on torch table from 1/8" stock

P.C. & Seat mounting metal:

- [1] 144" 4×4" 1/4" thick angle Iron

- [1] 88" 2×2" 1/4" angle iron

- [1] 192"×4" 3/8" plate

=Cut List: Power Cube

Cut List: Pulverizer

- 1-7/8" shaft -

- 2x4" square tubing

- Sheet metal

- Plates -

- Square Tubing -

Cut List: Quick Attach Plates

(See Open Pario for design)

- [6]1"x5" pins (30") - $10

- [129"] 3/16"x3" sq tubing - $46

- [113"] 1/2"x3" flat - $34

- [6"] 1" DOM tubing - $15

- [24"] 1" rebar - $3

- [66"] 1/4"x2" flat - $6

- [6"] 1/2" rebar - $1

- [15"] 3/4" threaded rod - $3

- [8] 3/4" lock nuts - $1.60

- [2] 3/4" nuts - $0.40

MATERIALS FOR EACH QA PLATE - $124

Cut List: The Liberator

U-Channel Frame

Arms, feet, hopper supports, hopper mounting

- [4] 4”x6”x3/8” – 72” long – heavy angle arms

- [4] 1/4”x10”x10” plate - feet

- [2] 1/4”x2”x2” sq. tubing, 48” long – back support

- [2] 1/4”x4”x4” angle , 40” long – angle front support

- [2] 1/2”x2”x12” flat - hopper mounting plate

- [2] 1/2"x3"x18" flat - hopper mounting plate

Drawer

Press Foot

- 1”x4”x10” plate

- 1”x6”x12” plate

Roller Guides

Grate

- [2] 1/4”x2”x2” angle, 6'

- [2] 1/4”x2”x2” angle, 3'

- 1/4”x2” bar, 71.5”

- 3/8” rebar, 105'

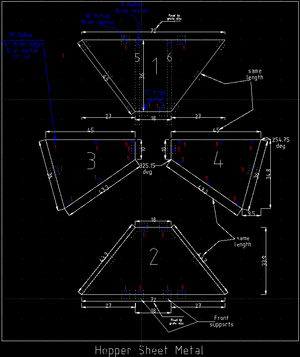

Hopper Sheet

- [1] 5'x10'x1/8" sheet

Other

- [8] 3”x3”x1/2” - cylinder mounts for both cylinders

- 2.5”x3/16” sq. tubing, 98" long - sleeves

- 1” shaft, 6” long - main cylinder mount

- 1” shaft, 6.5” long (shaker)

- 2”x2”x1/4” tubing, 3' long (2)

- 4”x4”x1/4” angle, 3' long (2)

Bolts

Functionality list:

- [22] 5"bolts+nuts + [44] washers to suit to attach re-enforcing tubes, angle-irons & H/cylinders to L-arms.

- [40] 3/4x5-1/2", with [40] washers for one side and [40] metal lock nuts for the other side. For wheel plates & cylinder plates.

- [42] 3/4"x9" bolts, [80] washers, and [40] metal lock nuts. This is for the assembly of the main frame.

- [16] 1/2"x2" bolts + [16] nylon lock nuts + [16] lock washers to suit. Motor attachment to motor QA/interface plate. Equivalent to 32" of threaded rod.

- [8] 3/4"x2" bolts for motor; [8] nuts to weld; [8] lock washers. Attachment of motor interface plate to frame.

- [32] 5/8"x2"bolts + [32] metal lock nuts, [32] lock washers to suit. Mounting of bearings to frame.

- [32] 9/16"x2" fine thread bolts, [32] washers, [32] nylon lock nuts. Attachment of wheel to wheel hub. Includes studs, nuts, and washers.

- [4] 3/4"x4.5" bolts; [8] nuts; [4] nylon lock nuts. Mounting of wheel bushings to wheel shafts.

TOTALS:

- [40] 3/4"x5.5" bolts

- [42] 3/4"x9" bolts

- [4] 3/4"x4.5" bolts

- [8] 3/4"x2" bolts

- [120] 3/4" washers

- [80] 3/4" metal lock nuts

- [16] 3/4" nuts

- [4] 3/4" nylon lock nuts

- [8] 3/4" lock washers

- [16] 1/2"x2" bolts

- [16] 1/2" nylon lock nuts

- [16] 1/2" lock washers

- [32] 5/8"x2" bolts

- [32] 5/8" metal lock nuts

- [32] 5/8" lock washers

- [32] 9/16"x2" bolts

- [32] 9/16" washers

- [32] 9/16" nylon lock nuts

Hydraulics

Main

Parts from Surplus Center:

Functionality list:

Note: Green indicates finalized shopping list from Surplus Center. Blue indicates list from McMaster Carr. Red is Dalton Hydralics. See Parts Sourcing for contact information.

- [8] 1-7/8" Flange Bearings - [1] or 2-1/2" Flange Bearings [2]

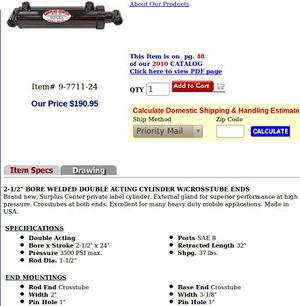

- [2] Front Loader cylinders - 36" - $174 - 48 5/8" retracted length - [3]

- [4] 3/8 NPTM x 1/2 NPTF 90 SWIVEL [4] for Front Loader Cylinders up to hose

- 4.9 square inch area at 2500 PSI implies 12000 lb of force for each cylinder

- [4] QA plate hydraulic cylinders

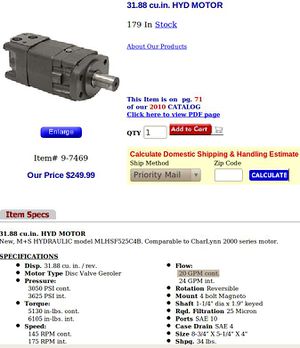

& 2 Rear Loader[5] - [4] Motors - [6]

- [2] 1-1/4 SHAFT COUPLER W 5/16" KEYWAY - [11]

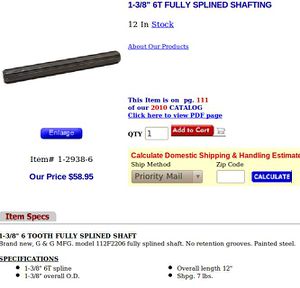

- [2] 1-3/8" 6T fully splined shafting - [12]

- [2] Female 1-3/8" 6T spline coupling - [13], $30 each

- [12] 1.875" double split shaft collars - [14]

- got 10 double split

- got 2 single split - [15]

- [1] 1/2" male QC tip, which already have female part [16]

Valves

- [1] 3-spool motor valve, 25 gpm - [17], $288

- [4] 1/2" Quick Couplers [18] - for motor valve work ports

- [4] 1/2" NPT M to NPT M 90deg Elbow for Motor Valve working ports [19] - for 2 sets of work ports to wheel motors

- [4] 3/4" NPT quick couplers - Dalton Hydraulics - 2 for in/out, 2 for auxiliary work ports

- [2] 1/2 NPT hex nipples [20]-for auxiliary pair of motor valve work ports

- [2] 3/4 NPT hex nips [21] - in and out of valve

- [2] 3/4 NPT to 1/2 NPT bushing [22] - auxiliary work ports

2 Spool Prince Valve

- [2] 3/4" NPT nip for inlet/outlet - [23]

- [1] 3/4" NPT tee (already have these) for inlet

- [2] 3/4" to 1/2" bushings - [24]

- [1] 1/2" NPT male elbow - [25]

- [2] 1/2" quick coupler pairs - [26]

Cushion Valves

- [2] 1/2 NPT 30 GPM 1500-3000 PSI HYD CUSHION VALVES - [27]

- [4] 1/2" male QC tips to plug into valves, which already have female QCs [28]

- [2] 1/2 NPTM x 1/2 NPTF swivel [29] for cushion valve to mount tees, for separating to right and left cylinders; only one swivel needed per cushion valve

- [4] 1/2" nip - [30] - going from between swivel and tee.

- [4] NPTF Tee [31]- 4 for loaders only, not QA plates

Power Cube

- Note: pump is already obtained

- [1] Coupler half, 5/8" - $10

- [1] Coupler half, 1" - $10

- [1] Solid spider - $14

- [1] Suction strainer, 2" to 1-1/4" - [32] - $23

- Use for dual Power Cubes

- [1] Use 2" coupler from bix box store to thread into Power Cube frame

- [1] Pressure relief for power cube bypass- [33]

- [1] 20 GPM return Line Filter - [34]

- [1] 3/4" NPT Swivel for return line filter going into frame - [35]

- [2] 3/4" NPT hex nip on both sides of filter - [36]

- [1] 1"-3/4" NPT reducer bushing for frame receptacle for return filter - [37]

- [1] 3/4" quick coupler for return line to filter

- [2] 1/2" quick couplers for main power lines

Hoses:

- [1] 2 foot hose from pump outlet to return line filter - [38]

- [2] 10 foot hoses, already have these - [39]

Pressure Bypass:

- [1] 1/2" NPT Bypass valve - [40]

- [3] 1/2" Quick couplers - 1 complete for tee near pump, one going from return filter to tee, and male tip for return line. This gives one extra female quick coupler left over. This set of 3 QCs does not cover hoses going from and to the PowerCube.

- [4] 1/2" NPTF hex nip for one and other side of tee, on both tees - [41]

- [2] 1/2" NPTF tee - from outlet of pump to pressure bypass, and from bypass valve into return line filter - [42]

Hoses

Between Motor Valves & Motors

- [4] 1/2" X 36" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE for in/out of the valves [43]

- [4] 1/2" X 36" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE for in/out of front motors [44]

- [4] 1/2 X 1/2 X 1/2 NPTF TEE [45]

- [4] 1/2" X 48" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE for rear motors [46]

Motor Case Drains

- [2] 1/4" X 72" NPTM 2750 PSI HYD HOSE to run parallel with tractor sides [47]

- [1] 1/4" X 30" NPTM 2750 PSI HYD HOSE from Tee to Tee in return hose [48]

- [1] 1/4" X 36" NPTM 2750 PSI HYD HOSE to Rear Motors [49]

- [3] 1/4 X 1/4 X 1/4 NPTF TEE [50]

- [3] 1/4 NPT hex nipples [51]

- [4] 1/4" NPT quick couplers are already with the motors

Front Loader

- [2] 1/2" X 12" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE from Valves to Cushion [52]

- [2] 1/2" X 36" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE for left front loader cylinder [53]

- [1] 1/2" X 48" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE for right front loader cylinder [54]

- [1] 1/2" X 60" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE for right front loader cylinder [55]

Front loader QA Cylinder Hoses

- [4] 3/8" NPTM x 1/2" NPTF swivel - [56] - swivels for QA cylinders

- [2] 1/2" nips - going from cylinder swivels to tees - [57]

- [2] 1/2" NPTF tees - from cylinder to hoses - [58]

- [2] male QC tips - for plugging into control valves - [59]

- [2] 1/2" X 48" NPTM 3000 PSI HYD HOSE [60]

- [1] 1/2" X 120" NPTM 3000 PSI HYD HOSE [61]

- [1] 1/2" X 144" NPTM 3000 PSI HYD HOSE [62]

Rear Loader Hoses

- [2] 1/2" X 12" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE to Cushion Valve [63]

- [1] 1/2" X 60" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE [64]

- [1] 1/2" X 96" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE [65]

- [1] 1/2" X 84" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE [66]

- [1] 1/2" X 120" 1/2 NPTM X 1/2 NPTM 3000 PSI HYD HOSE [67]

Rear loader Q.A. Cylinder Hoses

- [4] 3/8" NPTM x 1/2" NPTF swivel - [68] - swivels for QA cylinders

- [2] 1/2" nips - going from cylinder swivels to tees - [69]

- [2] 1/2" NPTF tees - from cylinder to hoses - [70]

- [2] male QC tips - for plugging into control valves - [71]

- [2] 1/2" X 48" NPTM 3000 PSI HYD HOSE [72]

- [1] 1/2" X 120" NPTM 3000 PSI HYD HOSE [73]

- [1] 1/2" X 144" NPTM 3000 PSI HYD HOSE [74]

Seat

- [1] Tractor Seat [75]

|

Cost

Basic Structure

This is about a buck fifty per pound of the 2214 lb machine, or about the going price of tomatoes. That is without the PowerCube. If you use an off-shelf 18 hp engine – the price may be $1225 ($500 for 18 hp engine + $200 pump + $225 frame + $300 balance of system). The total is then $4808.

Steel Tracks

- Chain - 80 feet - $270 at $3.37/foot

- Links - $28

- Rebar - 140' at $1.57/foot - $220

TOTAL for Wheel Tracks - $518