Dairy Milker/Research Development

Jump to navigation

Jump to search

| Dairy Milker | ||

|---|---|---|

| Home | Research & Development | Bill of Materials | Manufacturing Instructions | User's Manual | User Reviews |

| |

Research

- Dairy Milker Function is to yield milk from dairy cows.

Theory

Relevant Links

Building Your Own Dairy Milking Unit

Conceptual Notes

Development

Overview

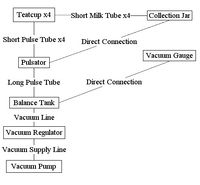

- Milking Unit are the components that attach to the dairy cow and produce pulses for alternating vacuum/atmospheric air entry cycles

- Vacuum System is the components that produce and regulate the vacuum level

Milking Unit

- Teatcup Liner - is the component that attaches onto the teats of the dairy cow. The teatcup liner can be made of rubber or silicone, and has two segments, a mouthpiece and a barrel. The mouthpiece makes contact with the teats while the barrel fits inside the teatcup shell.

- Teatcup Shell - is the component that contains the teatcup liner. The teatcup shell is a stainless steel hollow cylinder with an opening at the top for the mouthpiece of the teatcup liner, an opening at the bottom for connection to the short milk tube, and an opening at the side for connection to the short pulse tube.

- Short Milk Tube - is the component that connects the bottom of the teatcup shell to the top of the collection bucket. Milk flows from the teatcup liner through the short milk tube to the collection bucket.

- Short Pulse Tube - is the component that connects the side of the teatcup shell to the pulsator.

- Collection Bucket - is the component that accumulates the milk yielded from the dairy cow.

- Collection Lid - is a round narrow metal disk that covers the top of the collection bucket, mounts the pulsator, and

- Collection Gasket - is a round rubber component that seals between the collection bucket and collection lid.

- Pulsator - is the machine that alternates between applying vacuum at the teatcups and admitting air at atmospheric pressure to the teatcups

- Normal pulsator rate (rate of opening and closing) is 60 per minute. Pulsation ratio (vacuum time to air entry time) can be 50:50.

- 1 port to pulse line to vacuum reservoir

- 1 port to long pulse tube to claw

- 1 port to atmosphere

- Runs on DC current, usually 12V or 24V

Vacuum System

- Vacuum Gauge

- Placed inline with the pulsation lines and also between the vacuum reserve tank and vacuum regulator

- Measures vacuum pressure

- 2 ports

- Vacuum Reserve Tank

- Distributes vacuum to the pulsation header lines and milk header line

- Buffers the vacuum level for when air enters the vacuum system

- 1 port for milk header line

- 2 ports for pulsation header lines

- 1 port for main vacuum supply line

- Vacuum Pump Filter

- Prevents particulates from entering the vacuum pump

- 1 port for intake to main vacuum supply line

- 1 port for outtake to line to vacuum pump

- Vacuum Pump

- Applies a partial vacuum in the system

- 1 external port

- 1 vacuum port

- Vacuum Regulator

- Prevents vacuum level from increasing excessively by allowing air into the vacuum system when the vacuum level reaches a preset value

- 1 external port

- 2 inline ports

- Vacuum Relief Valve

- Prevents vacuum level from increasing excessively by allowing air into the vacuum system when the vacuum level reaches a preset value in case the vacuum regulator fails

- 1 external port

- 2 inline ports

- Sanitary Trap

- Separates the air-only vacuum system from the milk collection system

- Prevents liquid and particulates from the milk collection system entering the vacuum system

- 1 port to vacuum system

- 1 port to milk flow system

Design

- Requirements

- Speed

- Throughput

- Weight

- Size Constraints

- Feed stock

- Design Description

- Calculations

- Drawings and Diagrams

- Concept and Alternatives

- Full Design Views

- Cut-away Views

- Exploded Parts View

- 3D Renders

- Decisions

- Project Team

Industry Standards

| Industry Standard | GVCSTool |

|---|

Funding

Wanted: List of expenses for prototyping and documenting GVCSTool

Peer Reviews

Wanted: Peer reviews from the scientific community regarding the R&D of GVCSTool

Experiments and Prototypes

Wanted: Empirical data on performance