CEB Press/Manufacturing Instructions/Detroit Fab Lab Solenoid Driver

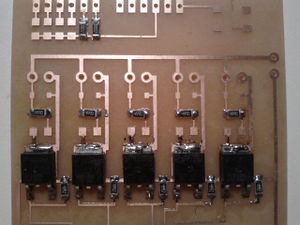

The Detroit Fab Lab has provided a custom-manufactured board that offers the five solenoid driver outputs required by the CEB Press. The card plugs into the Arduino Breakout Shield. The Five pins used to drive the five solenoid connections are as follows:

- D11

- D10

- D9

- D6

- D3

Here is some sample source code to test the five connections. Warning: Connecting the drivers to the solenoid unit incorrectly can ruin the unit. In particular, you should watch the polarity of the connections and ensure that opposite sides of one hydraulic circuit are not turned on by the solenoids at the same time. It is recommended that the board be fully tested first and then connected to the solenoid drivers. After this, circuit connections should be double checked before operating the solenoids.

int pwm_a = 11;

int pwm_b = 10;

int pwm_c = 9;

int pwm_d = 6;

int pwm_e = 3;

int i;

void setup()

{

//

pinMode(pwm_a, OUTPUT);

pinMode(pwm_b, OUTPUT);

pinMode(pwm_c, OUTPUT);

pinMode(pwm_d, OUTPUT);

pinMode(pwm_e, OUTPUT);

Serial.begin(9600);

}

void loop()

{

fade_channel(pwm_a);

fade_channel(pwm_b);

fade_channel(pwm_c);

fade_channel(pwm_d);

fade_channel(pwm_e);

}

void fade_channel(int channel)

{

Serial.println("Fading pwm channel to max: ");

Serial.println(channel);

for (i=0; i<=255; i++)

{

analogWrite(channel, i);

delay(100);

}

Serial.println("pwm channel at max.");

delay(1000);

Serial.println("fading down.");

for (i=255; i>=0; i--)

{

analogWrite(channel, i);

delay(100);

}

Serial.println("pwm channel at 0.");

delay(1000);

}

digikey parts

Bill Of Materials for CEB Press Driver Shield v1.0

Qnty Description Part # URL

- 5 Power N MOSFET RFD16N05LSM9ACT-ND http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=RFD16N05LSM9ACT-ND

- 5 Green LED 160-1169-1-ND http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=160-1169-1-ND

- 5 Diode 641-1331-1-ND http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=641-1331-1-ND

- 5 499 Resistor 311-499FRCT-ND http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=311-499FRCT-ND

- 5 49.9k Resistor 311-49.9KFRCT-ND http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=311-49.9KFRCT-ND

- 3 10k Resistor 311-10.0KFRCT-ND http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=311-10.0KFRCT-ND

- 6 2 Pos Terminal ED1514-ND http://search.digikey.com/scripts/DkSearch/dksus.dll?vendor=0&keywords=ED1514-ND

- 1 reset switch SW262CT-ND http://search.digikey.com/scripts/DkSearch/dksus.dll?Detail&name=SW262CT-ND

- 2 6 Pos Header A1913-ND http://search.digikey.com/scripts/DkSearch/dksus.dll?vendor=0&keywords=a1913-nd

- 2 8 Pos Header A1914-ND http://search.digikey.com/scripts/dksearch/dksus.dll?pname&site=us&lang=en&WT.z_cat_cid=Dxn_US_US2011_Catlink&name=A1914-ND

- 1 PCB

hints and tips

http://en.wikipedia.org/wiki/PCB_Milling

http://reprap.org/wiki/Automated_Circuitry_Making

materials required

- soldering iron

- thin coreless solder

- rosin flux paste or liquid

- multimeter

- tweezers

- steady hand

- good eyes or a magnifying glass

steps

- gather materials

- (need to add section on how to mill board)

- soldering

- plan ahead

- start with the smallest and shortest parts

- apply flux to one of the copper sides

- put a little solder on the tip of the iron and apply a little solder to that side

- apply flux to both sides

- hold piece in place on top of the solder

- for the diodes, leds, and swtich, double check the orientation

- while holding in place with gentle force, tap the iron onto the solder already on the board

- visually confirm the connection and placement

- apply flux to the other side

- add solder to the iron and connect the other side

- repeat

- it helps to do each step for multiple components, making progress on them as a group

- plan ahead

- mosfets

- apply flux to the two copper leads and the large copper square

- add solder to the iron and apply to the two leads

- place and hold the mosfet

- while holding in place with gentle force, tap the iron onto the solder already on the board, connect one lead and then the other

- take care to align correctly, it is difficult to turn once two leads are attached

- optionally add more solder to the leads

- flux and solder the other side to the copper square

- a heatsink may be prudent here

- headers

- flux on the base

- push the header through its holes, but keep it elevated a little

- place your iron in the gap at the front of the header, pushing down on the board

- feed solder from the side

- repeat

- reset switch

- wait till after the headers to do the switch so it wont be in the way

- posts

- the home stretch

- using an exacto knife clean out the holes from the bottom

- push posts through and solder

- test

notes

orientations with switch at top:

- diode - grey stripe on left

- led - green stripe on left

- switch - metal part reaching to base is on the right