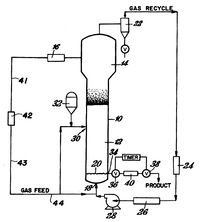

Fluidized bed reactor

Fluidized bed reactor (FBR) are chambers that allow the mixing of liquid or gas substrates with powdered catalysts such that the catalyst acts like a fluid, maximizing mixing and catalyst action. The basic configuration is detailed to the right where a substrate is passed upward through the chamber under pressure through a plate that supports the catalyst. FBRs are essential production of many materials and chemicals and is needed for several basic capabilities of the GVCS.

FBR for bioplastic production

As part of the OSE product ecology a reactor that could be used for ethanol dehydration and ethylene polymerization is a proposed route to locally produced renewable bioplastic. Due to the nature of the subtrates, powdered catalysts, and optimal catalytic conditions FBRs have demonstrate superior performance with high process reactivity and selectivity.

Literature and patent review

US patent 4,003,712 issued to Miller on Jan. 18, 1977 details a fluid bed reactor for use in a olefin polymerization.

Links

http://en.wikipedia.org/wiki/Fluidized_bed_reactor

http://www.fischer-tropsch.org/Bureau_of_Mines/ri/ri_6209/ri_6209.pdf