April 2011 Production Run BOM Combined Cut List

Jump to navigation

Jump to search

- See also April_2011_Production_Run_BOM_Combined_Cut_List_Collapsed

- See also April_2011_Production_Run_BOM_Combined_Cut_List

- See also April 2011 Production Run BOM

Cut List: Tractor (x3)

- [90.3'] 1/4"×4"×4" square tube for base (after 16" shorten) -> 300' total, 44" min

- [168"] 1-7/8" axle shafts - 42' total -> Need 40' and 56", 28" min

- [34"] 1-7/8" DOM to mount shafts through the frame. -> 102" 3.5" min

- [32"] 2" pipe (wheel bushings) -> 96" total, 8" min

- [240"] 6"×3" 3/8" rectangular tubes for front loader arms -> 60' total, min 45"

- [24"] 6"×4" 1/2" angle-iron to attach re-enforcing tubes to Loader arms -> 6' total, 6 inch min pieces

- [120"] 8"×1/2" steel plates to mount flange bearings and hydraulic motors to frame -> 30' total, 10" min

- [56"] 6"×1/2" QA-plate to mount motors to QA-motor plate, and cylinder bases -> 14' total, min 8"

- [24"] 4"×1/2" plate to weld to H-cylinder base plates -> 6' total, min 6"

- [12] 1" diameter-hole nuts to weld into above plates -> total of 36 nuts

- [36"] 1/4"x4 plate to mount Valves to -> total 9', min 3'

- [48"] 5"×1/2" plate to connect Front H-cylinders to loader-arms. -> 12' total, min 2'

- [40"] 10×1/2" plates to make wheel mounts -> 10' total, 10" min

- [32"] 4"×1/2" plate cut diagonally to make [16] gussets -> 8' total, min 4"

- [12] thrust bearings - in the form of large washers with 1-7/8" hole - torch these on torch table from 1/8" stock -> 36 total - do from hopper spare material (4 sq feet required)

- [28"] 1”x3”, 7" long slabs for loader eyes - 7 feet total, 7" min

- 70' of 3/8" Chain - total 210'

- 4 Links - $28; total 12 links

- Rebar - 121' of 1" rebar -> total of 363' of rebar (18 sticks + 3 feet), min 20"

Power Cube & Seat mounting metal:

- [144"] 4×4" 1/4" thick angle Iron -> total of 36', min 3'

- [88"] 2" 1/4" angle iron -> total of 22', min 3'

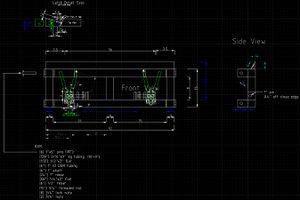

Cut List: Power Cube III (x5)

- [10'] - 27x29 base, 20 height thereafter; 1/4"x4"x8" mild steel square tubing - min. 13", 10' total now

- 1/4"x4"x4" angle verticals – 2 of them 20” tall, plus top -, min 13", 10' total now

- [48"] 4"x3/8" flat for fingers - 4' total now

- Pump mount plate - 1/4"x6"x8"

- [112"] - 1/4"x2" angle - engine mounting - 112" total now

- eyes

Cut List: Pulverizer (x1)

- [36"] plates 1/2"x8", shaft mounting -> total 36", min 12"

- [36"] tines sleeves 3” long - tube to fit 1-7/8" shaft -> total 36", min 3"

- [240"] tine blades, 1/4"x2" flat - 20' total, min 5"

- [56"] 1/4"x2"x4" is 56" long -> 56" total

- [48"] 2 arms 1/4"x2"x2" square tube, 2' each -> 4' total

- [2] arm sleeve, 3/16"x2.5"x12”, [2] depth sleeve, 3/16"x2.5"x6” ; 6” rostrum sleeve -> -> 42" total, min 6"

- shaft, 1-7/8"x54” long - 54" total

- [2] height adjust 15”, 2x2x1/4 sq tube - 30" total

- sheet 4'x33”x1/8" total

- [2] sleeve attachment 4x1/2, 6" long -> 12" total, min 6"

- 1/2"x4" cut into 4,10-12 right trapezoid -> 22" total

- 1/2"x3" finger -> total 48"

- [2] 1/4"x2'x4' bucket metal -> 4'x4' total

- 1/4"x2'x2' square for 2 sides -> 2'x2' total

- 38” rostrum, ¼"x2"x2" tube -> 38" total

- 12 stub bolts and nuts, 3/4"

Cut List: Quick Attach Plates (x2)

(See Open Pario for design)

- [30"] for 6 of 1" pins -> 60" total

- [129"] 3/16"x3" sq tubing -> 258' total, min 15"

- [113"] 1/2"x3" flat -> 19' total

- [6.5"] 1" DOM tubing -> 13" total

- [24"] 1" rebar -> 4' total

- [66"] 1/4"x2" flat -> 132" total, min 3.5"

- [6"] 1/2" rebar -> 1' total

- [15"] 3/4" threaded rod -> 30" total

- [8] 3/4" metal lock nuts

- [2] 3/4" nuts

Cut List: The Liberator (x3 + ~4 Automation + 4 Hopper)

- [244"] U-Channel Frame- 7/16" thick heavy u-channel, 6" wide - 61' feet total, min 9", just get 3 sticks

- [42"] 2 pieces of 1/4"x2”x2” angle for closing off compression chamber - 126" total, 21" minimum

Arms, feet, hopper mounting plate (x3)

- [4] 4”x6”x3/8” – 72” long – heavy angle arms -> 72' total (will weld cut ends together)

- [4] 1/4”x10”x10” plate - feet-> 10' total

- [2] 1/2”x3”x12” flat, [2] 1/2"x3"x14" flat - hopper mounting plate -> 13' total, 12" min

Drawer(x3)

- [1] 1"x7" flat, 12" long (if no 1x7, 1x8 is ok) -> total 3'

- [2] 1/4"x5"x13.5 flat -sides -> total 81"

- [1] 4"x6"x1/2" tube, 12" long - spacer-> total 3'

- [1] 3"x6"x1/2" angle, 12" long – back of drawer -> total 3' (is there 3x5 heavy angle?)

- [2] 1/2"x2"x31.5” flat - roller guides -> total 15'8"

- [2] 1/4"x2.5"x31.5” flat - roller guides -> total 15'8"

- [2] 1/2”x3”x12” v groove mounts -> total 6'

- [1] 1/2”x4” flat vertical support, 12" long -> total 3'

Press Foot and Cylinder Assembly (x3)

- [1] 1”x4”x10” plate -> total 30"

- [1] 1”x6”x12” plate -> total 36"

- [2] 1/2"x3"x3" eyes -> total 18"

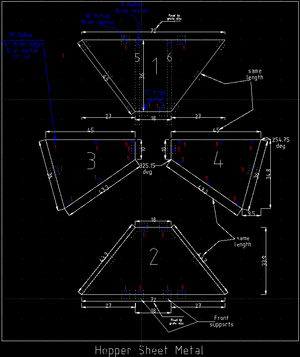

Hopper (x4)

- [1] 5'x10'x1/8" sheet -> 4 sheets total

- [2] 1/4”x2”x2” sq. tubing, 48” long – back support ->32' total, min 4'

- [2] 1/4”x4”x4” angle , 40” long – angle front support -> 26'8" total, min 40"

Grate (x4)

- [2] 1/4”x2”x2” angle, 6' -> total 48'

- [2] 1/4”x2”x2” angle, 3' -> total 24'

- [1] 1/4”x2” bar, 71.5” -> total 31'10" - added 2'(x4) for sensor mounting surfaces

- [105'] 3/8” rebar -> total 420'

Other

- [6] 3”x3”x1/2” - cylinder mounts for both cylinders -> total 54"

- 2.5”x3/16” sq. tubing, 98" long - sleeves -> total 24.5'

- [1] 1” shaft, 10” long - main cylinder mount -> total 30"

- [1] 1” shaft, 6.5” long (shaker) -> total 19.5"; eccentric - cutoffs from 1" rebar

- table – 1/8x10x28, and 12x28 -> total 56"x3 -> but included in cut ends of hopper

- Hopper shaker assembly-1/4"x8", 11" long, with bend - 44" total

- Cylinder adjusters - nuts and rod

- Shaker mounting - 1/4"x4" angle, 18" long - 6' total; guards from sheet metal cut ends

- Sensor mounting - done above, 1/4"x2"

- Controller mounting - 1/4"x6", 9" long for back, plus whatever provides balance ~16"@ -total 64"