Brick Pressing Rate Calculations

Introduction

Under the assumption of incompressible flow and fixed hydrauilic cylinder volume, the brick pressing rate of The Liberator can be calculated for a given hydraulic flow rate.

CEB Press v16.09, 2016 machine build. Machine is shown without hopper for manual loading with soil buckets. Used during the 2016 Seed Eco-Home Build. See CEB Press Genealogy.

The Liberator II - 2018

- 18 hp engine, DuroMax, 77 lb dry weight

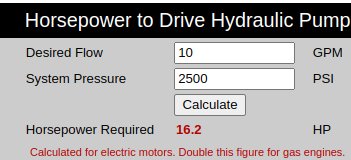

- Hydraulic Calculations state that HP required to drive a pump is HP = PSIxGPM/1714. Thus - for 2200 PSI - GPM=HPx1714/PSI=18x1714/2200=14.0 gpm. For 16 hp it is 16x1714/2200=12.5 gpm. Or, if we press at 2400 PSI - we have GPM=18x1714/2400=12.9 GPM

- Take 14 gpm pump -

Main Cylinder Volume, D= 5 inches, D_rod=2.5 inches

- Expansion Volume: Cylinder volume = 157 cu in (8" stroke)

- Rod volume = 39.3 cu in

- Retraction Volume - Cylinder volume-rod volume = 117.7 cu in

- Full cycle volume - (expansion volume + contraction volume) = 275 cu in

Secondary Cylinder Volume, d=2.5 inches, d_rod=1.25 inches, 14" long

- Expansion Volume: Cylinder volume (expansion volume) = 68.7 cu in

- Rod volume = 17.2 cu in

- Contraction Volume: Cylinder volume-rod volume = 51.5 cu in

- Drawer cylinder multiplier = contraction to expansion time ratio (used in control code) = 51.5/68.7 = 0.75

- Full Cycle Volume: (expansion volume + contraction volume) = 120 cu in

One complete cycle volume

One cycle volume = 395 cu in

1 gallon = 231 cu in

1 cycle = 1.7 gallons of fluid

Thus - 14 GPM should produce 8.2 full (4") block per minute (2200 PSI). 12.9 GPM should produce 7.6 block per minute (2400 PSI).'

That is quite attractive for an 18 hp as opposed to 55 hp engine of 2009

Design consideration: Blockage condition is defined as the condition when machine motion stalls when an impenetrable object, such as a rock, blocks the machine from moving. If one examines the motion cycle - this is possible ONLY during the pressing chamber closure motion after loading soil. The machine can be designed to stall upon a blockage condition, or it can be designed to keep bypassing at a blockage condition. Ideally, the algorithm allows a blockage condition to resolved automatically. If it can't be - there is no real disadvantage of 'design for engine stalling' in the blockage condition - ad a higher GPM pump should be used. Ideally, the control algorithm does not allow dwelling in a blockage condition.

Ratio of Main Cylinder Drift Velocity to Drawer Closure Velocity

- Main - 2.5" radius squared = 6.25 sq in

- Secondary - 1.25 raidius squared - rod .625 squared = 1.17 sq in

Velocity ratio of 6.25/1.17 = 5.3

Thus, during 7" drawer travel, main cylinder will move up 1.3".

Thus, need to keep main cylinder down for 1.3"

Main cylinder motion from above - 17.7 motions per minute x 8" = 141 inches per minute or 2.4" per second. Need to keep main cylinder down for 1/2 second to allow closure of drawer.

The Liberator - 2009

Let's take 25 gallons per minute for the design flow rate of The Liberator Beta v2.0.

The Liberator uses a 5x8x2 inch cylinder (diameter x length x rod diameter) for pressing, and a 2.5x14x1.125" cylinder for the soil loading drawer.

The effective volumes for both cylinders differ. This is because the cylinder rod takes up some volume - thereby reducing effective volume and force for the contraction part of the stroke. The expansion part of the stroke uses the full cylinder volume.

Main Cylinder Volume, D= 5 inches, D_rod=2 inches

- Cylinder volume (expansion volume) = 157 cu in

- Rod volume = 25 cu in

- Cylinder volume-rod volume (contraction volume) = 132 cu in

- Volume filled for a complete cycle of the cylinder (expansion volume + contraction volume) = 289 cu in

Secondary Cylinder Volume, d=2.5 inches, d_rod=1.125 inches

- Cylinder volume (expansion volume) = 69 cu in

- Rod volume = 14 cu in

- Cylinder volume-rod volume (contraction volume) = 55 cu in

- Volume filled for a complete cycle of the cylinder (expansion volume + contraction volume) = 124 cu in

One complete cycle volume

One cycle volume = 413 cu in

1 gallon = 231 cu in

1 cycle = 1.8 gallons of fluid

Pressing Rate Results

The results above yield 14 brick per minute results at 25 gpm.

We need to consider 10% inefficiency in the CEB hydraulic system (-1.4), intermittent operation of the soil grate shaker (-.5), and reduction of the main cylinder speed towards the end of the compression stroke (-1). This slowdown at the end of the compression stroke has been calculated as the condition where the last 1/2" of compression is slowed down by a factor of 4.

With these considerations, we obtain 11 bricks per minute for 4" thick bricks.

Similar calculations and reasoning for 2.5" thick bricks yield an overall results of 13 bricks per minute.