D3D Universal Product Page

https://www.opensourceecology.org/d3d-universal-2/

https://docs.google.com/drawings/d/e/2PACX-1vTVkidfueOUOhZ0cVG0g6uNqK0P2faTaL4Bui_-J2d_yBHhiwXcRRleMuiwNKoQb2BPN3BoSigFEvBl/pub?w=483&h=267

Value Proposition

- 24V system has less overheating issues and allows for higher speed of motion

- 1.2 nozzle comes stock stock for stronger, faster printing up to 10x faster than using standard nozzles. Comes with 0.8 and 0.4 nozzles for finer detail.

- Provide extrusion rate data.

- Stock 1.2 nozzle allows for 20 degree overhang angle, for example with 0.4 layer height with a 1.2 nozzle

- Marlin Inside - most popular and well-supported firmware

- Open source RAMPS v1.4 controller

- Comes with volcano heater block

- Uses magnetically-attached flexible spring steel build plate with Buildtak for quick release of finished prints

- Arduino IDE-powered firmware uploads

- Ready upgrade to 120V fast insulated PEI heatbed for eco-friendly 30% energy savings over standard heated beds

- Uses modular Universal Axis system

- Ready upgrade to 12"x12" print bed using a single additional z axis

- Ready upgrade to D3D Pro version allows reuse of Universal Controller and all Universal Axis parts

- INCLUDES plotter quick-attach tool head that converts your 3D printer to a plotter in seconds

- Can use a CNC hole drilling spindle module for making circuit through-holes

- Innovative belt drive on Z axis allows faster motion and elimination risk of destroying the print surface

- OSE-design open source extruder comes with Automatic bed leveling inductive sensor, print cooling fan.

- Clog-free design uses open filament pathway for fixing any clog in seconds

- Machine comes with blueprints for upgrading to a

- Only 3D printer in the world with an Unlimited Lifetime Guarantee.

Microfactory Site

Open source, OSHWA compliant design

Metal, fire resistant frame

Automatic bed leveling

First layer fine tuning feature

LCD Screen

200 mm/s print speed

Print bed is stationary except for the Z direction, allowing for fast printing of tall, columnar objects

PEI build plate surface

Versatile Titan Aero Extruder by E3D

Filament runout sensor

1.75 mm filament

3 mm filament

Trinamic stepper drivers

Universal Axis Motion System

Interchangeable tool head

Lowest unique part count

Most widely used 3D printer in the world

Can be built using common, off-the-shelf parts

UVP

The only printer in the world:

- with which you join an OSPD movement and a development project to change the world

- with an Unlimited Lifetime Guarantee

- with an insulated heatbed for 30% energy savings

- That comes stock with 1.2 nozzle for fast printing

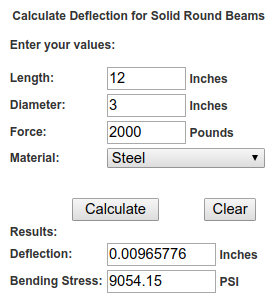

- Uses a modular construction system, the Universal Axis, that is is highly scalable to larger size (100x) and higher tool torque (1000x). See beam deflection calculator for using 8 mm rods compared to 3" rods for the Universal Axis - Beam Deflection Calculator - for a practical case of a 12" long 8 mm rod system vs a 24" long 3 inch rod system.