December 2019 OSEmail

Sent

Dear Friends and Supporters,

We are rolling out the Open Source Microfactory STEAM Camp internationally. We have our first event on Jan 25-Feb 2, 2020 - to be held in 3 locations on 2 continents at the same time: Belgium, Virginia, and Texas. We are making collaborative product development a reality. Check out the announcement: https://www.opensourceecology.org/steam-camp-january-2020/

and check out my 2 minute video:

https://www.youtube.com/watch?v=OeNSuf6Ofmk

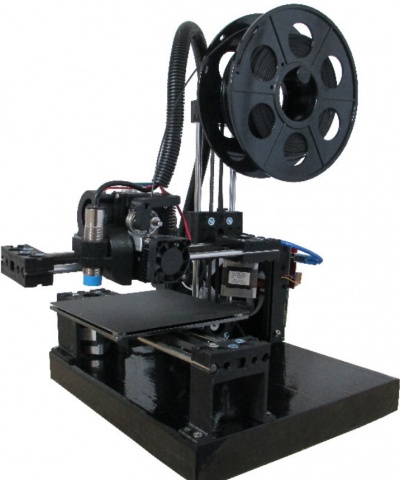

And we are shipping! We are rolling out our first product releases, our first ever buy button on our website where you can order our 3D printers that we ship to your doorstep; the D3D Universal, and the D3D Pro. These are the products that we developed during the Open Source Microfactory Startup Camp, which was a very productive time. The D3D Universal is what we will use in the STEAM Camps.

https://www.opensourceecology.org/d3d-universal-2/

Our specfic goal is NOT to produce a hobby printer, which you can get from China for 200 dollars. Our machines are designed for those interested in beginning a production business, for parts manufacturing, and for learning about CNC machine design - not to mention joining an open product development community. And we have just developed what we think is quite noteworthy: the world's first extruder that does not require a gear-down to use 3 mm filament - a Flexible Gearless design that works well printing rubber, and can use 1.75 mm filament interchangeably with 3 mm filament. See the last link. If you are into 3D printing, this may be quite exciting - if you are not yet - let's just say the Flexible Gearless an awesome development in the 3D printing community. Let me know your thoughts on this, and pass on the links to your friends.

We also released our production printer with eco-friendly low energy requirement - see https://www.opensourceecology.org/d3d-pro/. It's the only printer we know of with an insulated heat bed, as we care about the environment, and the insulation allows us to use 30-40% less energy to heat the bed.

Build prep is happening for the CEB Microhouse build in Belize - https://www.opensourceecology.org/ceb-microhouse-build-in-belize/ , with foundation laid, soil delivered to the site, and our new Soil Mixer ready to be added to our pool of open source machines.

https://wiki.opensourceecology.org/wiki/Soil_Mixer_2019

We are beginning the mixer build - at a cost of about $3k in materials for a one-step soil mixer which accepts raw soil, pulverizes it to a fine powder via hammer-mill action, adds a controlled amount of cement, and sprinkles in appropriate water content. Our machine would require 3 people to run. The price of the next comparable machine that does this is $48k operated by 15 people. Our goal is to normalize CEB construction as a practical and accessible way to do housing.

With this, we intend to produce stabilized CEBs for sale in America. We plan on doing a 3000 square foot CEB outdoor patio, retaining walls, and more modular houses at the Summer of Extreme Design-Build 2020 - https://www.opensourceecology.org/summer-x-2020/

So it's going to be an exciting year.

Summer X is coming! That is our most grand Summer of Extreme Design and Build and Startup Camp - 3 months where we build a bevy of CNC machines, more heavy machines, buildings, microhouses, and our next generation aquaponic greenhouse. We will build larger 3D Printers, and use 3D printing exensively to make rubber tracks and tires, plumbing pipes, wall panels, foundation forms, and other applications. We focus on open source livelihood creation as we teach people to be producers: of 3D printing filament, of stabilized construction block, plastic lumber, plumbing pipes, solar concrete, lumber, and more. Significant economic impact of our work may soon begin showing. In 2020, it will be better as, we actually have a program, curriculum, improved infrastructure, and staff.

As our next major milestone in our internet infrastructure, Michael Altfield, our senior sys admin, succeeds in installing Discourse forum software on our staging server. Technically speaking - this was a challenge to install its Docker container on a non-supported non-cloud infrastructure while waging documentation requests with a semi-supportive Discourse developer community, while addressing security and caching. But it's now documented as we blazed the trail so others can follow if they have a similar fat client architecture to our own.

Happy New Year, Marcin

Wished To Send

- We are rolling out the Open Source Microfactory STEAM Camp internationally. We have our first event - to be held in 3 locations on 2 continents at the same time: Belgium, Virginia, and Texas. We are making collaborative product development a reality. Check out the announcement: https://www.opensourceecology.org/steam-camp-january-2020/

and check out my 2 minute video:

https://www.youtube.com/watch?v=OeNSuf6Ofmk

- And we are shipping! We are rolling out our first product releases, our first ever buy button on our website where you can order our 3D printers that we ship to your doorstep. The D3D Universal is what we work with in the STEAM Camps - https://www.opensourceecology.org/d3d-universal-2/

Check out the D3D Universal:

Our specfic goal is NOT to produce a hobby printer, which you can get from China for $200. Our machines are designed for those interested in beginning a production business, for parts manufacturing, and for learning about CNC machine design - not to mention joining an open product development community. And we have just developed what we think is quite noteworthy: the world's first extruder that does not require a gear-down to use 3 mm filament - a Flexible Gearless design that works well printing rubber, and can use 1.75 or 3 mm filament interchangeably. See the last link. If you are into 3D printing, this may be quite exciting - if you are not yet - let's just say the Flexible Gearless an awesome development in the 3D printing community. Let me know your thoughts on this, and pass on the links to your friends.

We also released our production printer with eco-friendly low energy requirement - see https://www.opensourceecology.org/d3d-pro/. It's the only printer we know of with an insulated heat bed, as we care about the environment, and the insulation allows us to use 30-40% less energy to heat the bed.

- Build prep is happening for the CEB Microhouse build in Belize - https://www.opensourceecology.org/ceb-microhouse-build-in-belize/ , with foundation laid, soil delivered to the site, and our new Soil Mixer ready to be added to our pool of open source machines. We are beginning the mixer build - at a cost of about $3k in materials for a one-step soil mixer which accepts raw soil, pulverizes it to a fine powder via hammer-mill action, adds a controlled amount of cement, and sprinkles in appropriate water content. Our machine would require 3 people to run (1 to run tractor to load soil mixer and to load cement and 2 people to stack block on pallets). The price of the next comparable machine that does this is $48k for a soil crusher (7 people to load, 1 person to run tractor for initial soil - [1]) and mixer, which requires a team of 7 people (https://www.youtube.com/watch?time_continue=40&v=zpD42kWbDVA&feature=emb_logo)OSE's lean appropriate technology approach thus requires $3k and 3 people, compared to $48k and 15 people. Our goal is to normalize CEB construction as a practical and accessible way to do housing.

With this, we intend to produce stabilized CEBs for sale in America. We plan on doing a 3000 square foot CEB outdoor patio, retaining walls, and more modular houses at the Summer of Extreme Design-Build 2020 - https://www.opensourceecology.org/summer-x-2020/

So it's going to be an exciting year.

- Summer X is coming! That is our most grand Summer of Extreme Design and Build and Startup Camp - 3 months where we build a bevy of CNC machines, more heavy machines, buildings, microhouses, and our next generation aquaponic greenhouse. We will build larger 3D Printers, and use 3D printing exensively to make rubber tracks and tires, plumbing pipes, wall panels, foundation forms, and other applications. We focus on open source livelihood creation as we teach people to be producers: of 3D printing filament, of stabilized construction block, plastic lumber, plumbing pipes, solar concrete, lumber, and more. Significant economic impact of our work may soon begin showing. Wow.

Last time we has Summer X, it was wild. We did this among other things: https://www.opensourceecology.org/wp-content/uploads/2012/05/machines_4-bw-2-1024x450.jpg

In 2020, it will be better as, we actually have a program, curriculum, improved infrastructure, and staff.

As our next major milestone in our internet infrastructure, Michael Altfield, our sys admin, succeeds in installing Discourse forum software on our staging server. Technically speaking - this was a challenge to install its Docker container on a non-supported non-cloud infrastructure while waging documentation requests with a semi-supportive Discourse developer community, while addressing security and caching. But it's now documented as we blazed the trail so others can follow if they have a similar fat client architecture to our own.