Earth Area Required for a Solar Economy

![]() Hint: It takes $7.5T to go solar with PV (to buy 30TW of PV at current market prices), for 100% of energy use. 30TW would need to be installed in total accounting for 4x safety factor because the sun only shines 1/4 of the day). World now has about 1 TW (2022). Size of carbon credits is about $1T, so carbon credits can be put to PV instead. A good strategy would be to do exactly this: use that revenue to fund PV installs. But how does this work? Is this even worth it? Or, just install PV for customers to get off dinosaur crack? Hoever, the generative route may be more sound: instead of $7.5T, how fast can we do it with an investment of $1B? See OSE Theory of Liberation

Hint: It takes $7.5T to go solar with PV (to buy 30TW of PV at current market prices), for 100% of energy use. 30TW would need to be installed in total accounting for 4x safety factor because the sun only shines 1/4 of the day). World now has about 1 TW (2022). Size of carbon credits is about $1T, so carbon credits can be put to PV instead. A good strategy would be to do exactly this: use that revenue to fund PV installs. But how does this work? Is this even worth it? Or, just install PV for customers to get off dinosaur crack? Hoever, the generative route may be more sound: instead of $7.5T, how fast can we do it with an investment of $1B? See OSE Theory of Liberation

Area

About 100k square miles [1]

Wholesale PV Panel Cost

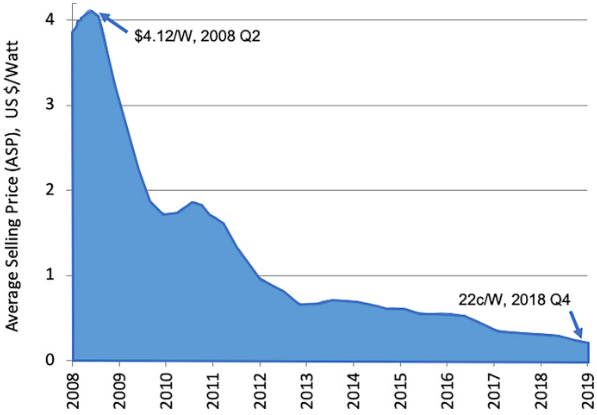

Alibaba - down to 16 cents per watt - [2]. Import them with 30% tariff [3].

Intro

Below, we motivate the solar economy transition on first principles, and propose a million PV entrepreneurs worldwide to transition the world to a solar economy by distributed PV panel production.

This would require other, simpler means to producing silicon. There is ongoing research into alternate routes for silicon production, see review [4]. But, silicon can also be produced with traditional means, in a bootstrapping approach, even if energy payback times are 2 years. But the article points out that the cost would be 7x higher if Chinese solar-grade silicon subsidies did not exist? And mentions billion dollar costs of solar grade silicon refining operations? Perfect place for open source zone refining. But, upgraded metallurgical grade silicon - is another more clean process.

Metallurgical grade silicon costs only 14-16kWhr/kg in energy to produce -- [5]. This energy requirement is much less electrolytic hydrogen, see Hydrogen Production. For comparison, Solar Concrete is only about 1 kWhr/kg.

For perspective - note that 1 kg of silicon (when transformed to PV cells) - can produce the equivalent energy of 100 tons of oil [6] (fact check this by doing the calculation).

Metallurgical grade silicon can be used to make solar cells - [7]. This appears to be 2008.

How is solar grade silicon made? Leaching with acid gets to 99.9% pure - [8].

Monocrystalline is 25% efficient and 38 cents per watt - [9]. It is made from a single crystal, sliced. [10]. Produced by Czochralski process [11], but requires semiconductor grade silicon. How is semiconductor grade silicon made? Requires the silanes and CVD of the Siemens Process.

One way to solar grade is quasi-mono silicon. [12]. Cost is down to 11 cents/watt. [13]

Another way to solar grade silicon is upgrading metallurgical grade. [14] Upgraded metallurgical-grade silicon (UMG-Si) - can you use induction heating to melt silicon [15]?

Promise of Upgraded Metallurgical Grade Silicon

Upgrading metallurgical grade silicon to solar grade seems to be the future. Appears to have a 1/2 year energy payback time [16], making the panel production stage more energy intensive than the production of the cells themselves!

Notes:

- 4 grams of polysilicon are required per watt of cells

- Polysilicon is 95% of PV market.

- Solar grade silicon can even be done with direct carbothermal reduction of silicon

- About 3x less emissions from UMG (Upgraded Metallurgical Grade) silicon than polysilicon.

Ferrosolar UMG Process [17]:

- Silicon itself is 20% of module cost

- Process uses induction heating, solidifying, leaching, vacuum, furnace heating. See Ferrosolar UMG Process

Other UMG process - [18]

Total Energy Use appears to be That Producible by 30TW of Solar

- http://landartgenerator.org/pdf/PosterSolar.pdf

- Cost would be $3-5 trillion, or a fraction of global GDP. [19]

- Then to summarize, WTF is this not happening by next year?

- Only 150 GW of panels are produced per year [20]

- Average consumption is 350W per person for 8 billion people. [21] - 3200 kwHr per person [22]. This means 3 TW needed (8B*350W). But need to multiply by 4 as sun shines 6 hours on average on any place, World. So say it's about 10TW need for installed PV. (yes, but doesn't include other than electricity.

- USA is 10kW per person including transportation, heating, cooking.

- 40% of all energy is electricity [23], ie, double the per capita electricity use to get rough estimate of total.

- Thus is we include all energy and not just electric - Taking best figures - we get about 30 TW installed capacity (including 4x safety factor as sun shines only 6 hours per day). This costs $7.5T for the PV panels. Integrated with housing, this costs no more.

- This means one decade gets us 1.5TW - need a few decades. But this is accelerating.

- OSE proposal - entrepreneurs get involved in PV module production en masse.

- Startup cost of PV manufacturing facility - about $1/W so $5M for a 5MW/year facility. But costs underneath are already 2/3 of finished panel cost, see NREL presentation slide 45 reference below. So highest open source advantage comes from vertical integration, which can arguably perform at lower capital cost than PV panel gigafactories.

- Startup plant for PV manufacturing - See [24] - full breakdown. Initial capitalizatin appears to be spread out over an undefined period. Looks like facility would be somewhere around $2M in equipment? See example of laminator and facility. [25]. 5MW per year is typical, for about 40kW actual power use on laminator. 5MW = 250W*(20,000). 20k panels - or enough for 100 facilities of 50kW each. In this model, the cost is 43 cents per watt, sale price is 64 cents per watt. This is in 2014, so it's a generation ago. Price of solar cells has been dropping - down to around 20 cents per watt for solar cells only [26]. Note that the actual silicon material is a small fraction of the PV module cost - processing is most of the cost.

Cost breakdown - wafer is 1/3, cell is 1/3, module is 1/3. Each has a 20% margin or such. See p 45 of [27]. But, this is 2011 - so it's about 2 generations ago in PV time.

Cost breakdown - wafer is 1/3, cell is 1/3, module is 1/3. Each has a 20% margin or such. See p 45 of [27]. But, this is 2011 - so it's about 2 generations ago in PV time.- Therefore, if we have a bunch of vertically integrated, open source startup entrepreneurs - how much capital would be needed? At a dollar a watt, it's $3T for the transition. Note that the simple calculation of $1/W of PV panels agrees with the Borntoengineer,com article above - which mentions 3-5 tees for the transition. However, we need to multiply this 4x because the sun shines a quarter of the day.

- For roughly 10 trillion (10E12), we need a number of 5MW (5E6)production plants. This number is: 2M entrepreneurs, to do it in a year. The limiting factor is likely to be the solar cells - the core of a PV Panel.

Solar Economy Transition

- Based on the above figures:

- If there are 8B people - one person in 4,000 would have a job as a photovoltaics entrepreneur. And in a multipurpose facility - this can produce the panels and then reconfigure to derivative functions such as solar steel, hydrogen, silicon, or concrete production. This gets us up to precision manufacturing and semiconductors - key to modern electronics for automation and for symbiosis with machines.

- Thus an imperative would be to demonstrate the feasibility of distributed, multipurpose production facility - known a sthe open source microfactory. At about $5M investment, it gets us to the capacity pointed out above and the low budget $5M is a small fraction of a military rocket or plane. (F35 costs around $100M).

- While the magnitude of solar capacity to be produced is staggering, it is only a tiny fraction of human effort in the larger picture, at Kardashev Scale of 0.0001. The worthwhile question becomes - are good ideas rapidly scalable? The answer lies in feasibility, and the answer to feasibility lies in understanding the rate-limiting steps. Is the limit in aluminum, glass, EVA, silicon, etc? What step is the limit? Then we address the limiting step and move forward. In general, within an open source economy (seamless efficiency of transaction from ideas to execution) - no material step is limiting - and no energy step is limiting. Even if we had to make biomass pellets to generate electricity!

- Verifying this as the fraction of global GDP - which is around $100T - the 3T still represents 3% of human effort.

Data

- Carbon credits market is nearing $1T annually [28].

- World goes renewable by 2050 [29]

- Carbon emitted per American

What I'm observing is that almost nobody - other than perhaps Elon Musk - is thinking clearly about the situation we are in. Allow me to explain.

Each dollar in the global economy emits (on average) 260 grams of CO2. If we spent $8000 each per year, we would have sustainability.— Vinay (@leashless) April 23, 2022