Hot Dip Galvanizing

About

- Kettles - copper causes premature kettle failure.

- Kettle manufacturer - [1]

- Wikipedia - [2]

- Zinc Ammonium Chloride - used as flux - [3]. Zaclon in Ohio makes it. [4]

- Coating thickness for 1/4" and above steel is 85 microns minimum. [5]

- Kettle inspections - tests wall thickness - apparently for wear and complete loss of metal. Wall thickness is measured ultrasonically in situ o a working kettle with molten metal. [6]

- Melting zinc - you can even melt on stovetop, here is a tiny wad of zinc melted into a mini-ingot [7]

- Hot-dip galvanizing design - MIG is good for weldments prior to hot dip, must be low Si - [8]. Info on welding galvanized steel

- Steels for tanks - [9]

- Materials - 'In the "old days" the common material was fire box steel. Some years ago "Max Ten" was specified which means the alloying agents in the steel would add up to no more than 0.10%. Today modern kettle makers know what can and cannot be used to make a galvanizing kettle. Certainly silicon, aluminum, and phosphorus contents in the steel must be VERY LOW. Also one MUST use the correct welding rod or else the welds will be "eaten up" by the zinc. In addition only the side walls can be heated (NEVER THE BOTTOM). Also the a horizontal stripe 6 inches high at the top of the walls and a horizontal stripe 12 inches at the bottom of the kettle are insulated and (NEVER HEATED). The maximum heat throughput through the walls is 10,000 BTU/sq.ft. on the heat zone of the side walls.'. Boilerplate steel. Firebox steel. Low Carbon Steel. In the same article, Dr. Thomas H. Cook Galvanizing Consultant - Hot Springs, South Dakota, USA says that kettles are not for DIY.

- Materials engineered for use in galvanizing operations - the specific property required is? Low in C and Si. It is flange or firebox quality steel. Boilerplate steel. [10]

- Sulfuric acid eats steel, but sulfuric acis is stored in steel tanks. Here is more about corrosion rates - a study - [11]

- Sulfuric acid does not eat polyethylene - [12]

Kettles

From a dedicated thread: [13]

- https://www.crithwood.com/ - consultant on HDG. Critical element is silicon.

- A. SAE/AISI 1006. Welding consumable must put down weld metal which has either (a) less than 0.05% silicon, or (b) between 0.11 and 0.25% silicon. It must not be between 0.05 and 0.11

- 35 years ago there was a steel (iron product) that was called "max ten." This meant that with the exclusion of iron the other ingredients all added together totaled 0.10%. Thus the carbon, silicon, phosphorus, manganese, etc. all added together could not exceed 0.10%. Another terminology was "fire-box steel." Still another terminology was Armco Iron (or steel). The usual thickness of steel (iron) kettles is 2 inches in North America and welded with very specific welding rod. The welds are normally x-rayed to be sure that they are good. Making a galvanizing kettle is NOT a "do it yourself" job. Columbiana Boiler in the USA and Pilling in Germany are major suppliers of hot dip galvanizing kettles. Through the heating zone on the sidewalls (excluding the top 6 inches and the bottom 9 to 12 inches which are insulated) it is allowed to transmit 10,000 Btu's/sq ft/hour with an expected kettle life of 10 years. High-velocity end-firing is the most efficient system with proper shielding near the burners. Looking from above the hot gases circle the kettle. The burners are on diagonal corners with initial firing along the long sides. The depth(numerator) to width(denominator) ratio should be about 1.5 to 2. E.G. considerably deeper than wide. I have published several articles in the journal METAL FINISHING which details these informations. I strongly recommend that you purchase a commercially made kettle and contract a qualified kettle furnace installer. Regards, Dr. Thomas H. Cook. Galvanizing Consultant - Hot Springs, South Dakota, USA

- A galvanizer told me recently that the proper welding rod is "FLEET 7." He also said that MIG equipment is better. The rod, or wire only has traces of silicon and phosphorus (also I think that low aluminum is important). Dr. Thomas H. Cook. Galvanizing Consultant - Hot Springs, South Dakota, USA

- The steel used for galvanising pots should conform to BS 2858 [affil. link to spec at Techstreet]. Also the higher the temperature of the zinc the more the dissolving effects. There are new zinc alloys available and new methods of maintaining the alloying elements in solution. These factors together can greatly reduce zinc consumption. Paul Markham furnaces - Burntwood, Staffs, UK

- Indian tank company - Gunatit Builders - [14]. We are an India based consulting company with more than 45 years experience in setting up hot dip galvanizing plants on a turnkey basis. Also, we are a manufacturer of entire galvanizing plant from process tanks to galvanizing furnaces and all equipment for galvanizing industry.

- Steel specification

. Steel suppliers -

. Steel suppliers -

- Dead Soft Quality plate is used in India - [15]

- Homemade tank lasts 6 months. Bought one - lasts 10 years.

- for Galvanizing Bath , in India, people use DSQ Plate (dead soft Quality) manufactured by SAIL

- Galvanizing kettle - must be kept on all the time - extra erosion if started/stopped?

- Ceramic kettle for small galvanized items, metal for large structural?

- Basic reason of deterioration in Galvanizing pot are 1 ) uneven heating 2 ) furnace design. 3 ) Deposition of Hard zinc (Dross) inside zinc kettle. 4 ) Quality of Pot materials.

- The best material for kettles is "CLASS A DSQ (Dead Soft Quality)" and "GP2"

- Books - Obtain and read the two books: "Hot Dip Galvanizing" [only $500 (https://www.amazon.com/dp/B00DMGAGRG/?tag=finishingcominc)] by Heinz Bablik and "Handbook of Hot-Dip Galvanization" [16]. Visit galvanizing plants including San Diego Galvanizing and LA Galvanizing.

- Ceramic pots up to 2.5 ton molten zinc can be made - [17]

- Ceramic crucibles - [18]

- Continuous vs batch - [19]

- Kettle life - under 7 years [20]

- Dross - loose iron/zinc in pot [21]

- Grades of zinc for continuous hdg - [22]

- Kettle pumpout - [23]

- Ceramic + induction - it seems clear that this is yet another good case for induction heating - [24]

Communications

(MJ emails the forum 2/9/2021)

Great thread, and I would like to post a meta discussion here. I am biased for open source, collaborative development - and I find the information presented quite good and I have a better feel for hot dip kettles now. At the same time - it is clear that learning the due diligence on the topic is a longer process. Could you perhaps do a summary article on the topic of kettles - for the small scale and professional alike? We are still trying to get to the bottom of the question: what is the cost, lifetime, and best practice for = a small scale, non-continuous operation kettle? Small scale means 55 gallon drum size kettle. With open source automation, we'd like to make such an enterprise feasible on a scale smaller than imaginable to date.

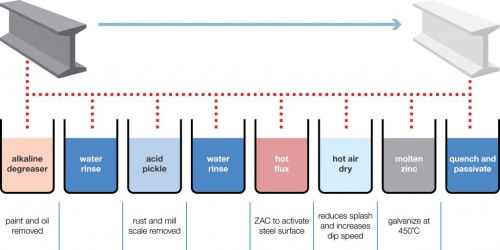

Process

From [25]

Howto

- Sand blast

- Base bath - 10 minutes min

- Base bath - 7 minutes min

- Flux - ammonium

- Actual dip - 3.5 minutes (until base metal reaches melt temp of 835F)

- Water - trapped water explodes, and is dangerous, so first dip is dangerous and venting must be assured.

- Zinc - 2400 lb blocks are the feedstock for hot dip baths. This is only 0.1 cubic meter - or 4 cubic feet.

https://www.aisc.org/globalassets/modern-steel/archives/2014/08/2014v08_galvanizing.pdf

More about surface preparation: [26]

Sourcing

- Acid -

- Base - KOH pr NaOH for grease - [27], NaOH doesn't require hot water.

- Ammonium chloride - $2/lb [28]

Zinc Ingots

See Zinc#Sourcing

- [29]

- Carter Alloys, 2" zinc balls [30]

- ACI - [31]

- Ney - [32]

- Industrial Metal Supply - [33]. Do they have ingot?

- Victory - [34]

- Milward - [35]

- Umicore - [36]

- Belmont Brooklyn - [37]

- AEM says zinc - [38]

- Ingots on Thomas Register - [39]

- Zinc Ingot on Thomas Register - [40]

- Zinc on Thomas Register - [41]