Ironworker prototype II design 1.0

Introduction

The OSE Ironworker Prototype II was completed in August, 2012. See blog post -

http://blog.opensourceecology.org/2012/08/open-source-ironworker-machine-prototype-ii-completed/

Design

See GrabCAD Ironworker Challenge for the design of Prototype II.

This is the design of Prototype I. The calculations may prove useful for other designers. It was scrapped because I couldn't find a flat/angle combination blade with a large cut capacity. Also, I found a design similar to a Scotchman more compelling, as it is much more versatile than this design.

See also: Hole Puncher Calculations

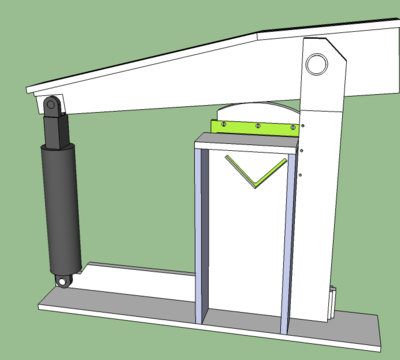

Design Concept

- A single lever arm attaches to the cylinder and pivots about a pin through vertical supports.

- The punch is located 8" from pivot, outside of the pivot.

- The shear is located 8" from pivot, inside of the pivot.

- The shear is a flat/angle combination blade, similar to this one. The blade would look like the one pictured on the right, and would slide up and down in high-carbon steel rails attached to the vertical supports. It attaches to a blade mound which attaches to the arm with a loose linkage that would only pull, not push. The arm pushes it via the rounded blade mount.

Arm/Cylinder Cost Analysis

This was to determine proper cylinder size and arm material for various capacities.

Summary

I calculated arm cost, length, and weight for a 5" vs 6" bore cylinder, a 120T vs 100T capacity, and a 1018 arm vs an A36 arm.

Conclusions

Whichever capacity you want is up to you.The 5" cylinder, and a 1018 type arm is the most sensible for either capacity. If you want a 100T capacity (1" holes in 1" metal, or shear 1"x10"), it will cost about $986 for the arm and cylinder. If you want 120T capacity (1.25" holes in 1" metal, or shear 1"x12") it will cost about $1194 for them.

Justifications

Arm type differences

I found that by using a 1018 arm instead of an A36, the cost is only about $60 extra in each case, but we shave off at least 100 lb by doing so. We should use a 1018 arm, as this much weight is worth $60 to a small girl fabricator.

Cylinder type differences

Using the 6" cylinder shaves off weight (around 70 lb) and length (8" per model) for the overall machine but is more expensive and would require extra labor, as it is the cross-tube type like we used on the CEB, and for the Ironworker we want a clevis.

- For a 100T Capacity, you save about $200 by using the 5" bore, so this is the clear choice.

- For 120T capacity, the savings are much less (only about $50) so if the extra weight and size shaved off is valuable, either cylinder choice would be valid.

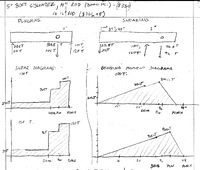

Calculations

- This also uses calculations found on the Hole Puncher Calculations page