Modular power cubes

Concept development

This work hopes to build upon existing development work on power cubes Tom:_Dallas_Log and various discussions.

The desire to design a multifuel diesel power cube with similar power output led to both the proposition for using engines with drive on the horizontal axis (a wider choice of engines) and the incorporation in the design for a method to allow diesel power cubes, which will be heavier than their petrol equivalents, to be man handled.

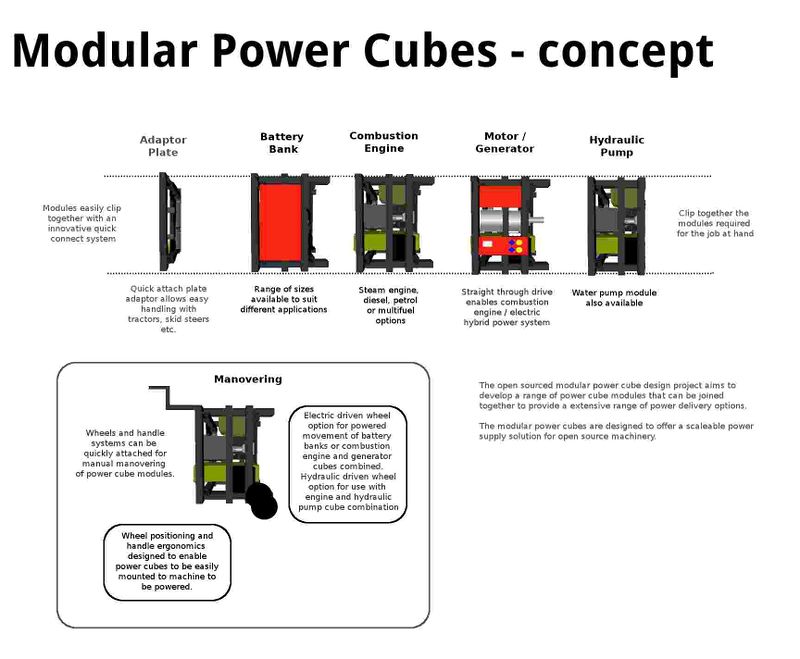

Modules

A number of different modules, some which provide energy, others that convert energy from one form to another can be combined depending on application and availability.

Power modules

- Petrol engine - rotational power

- Diesel engine - rotational power

- Steam engine - rotational power

- Battery bank - electrical power

Power conversion modules

- Electric generator - rotational power to electrical power

- Electric motor - electrical power to rotational power

- Hydraulic pump - rotational power to fluid power

- Water pump - rotational power to move water

- Mechanical transmission - changing speed and torque of rotational power

- Electric motor/generator with straight through drive - can be used with a source of rotational power, a clutch and a battery bank to provide a 'hybrid-electric' power source

Other modules

- Clutch module - allows rotational power to be disengaged

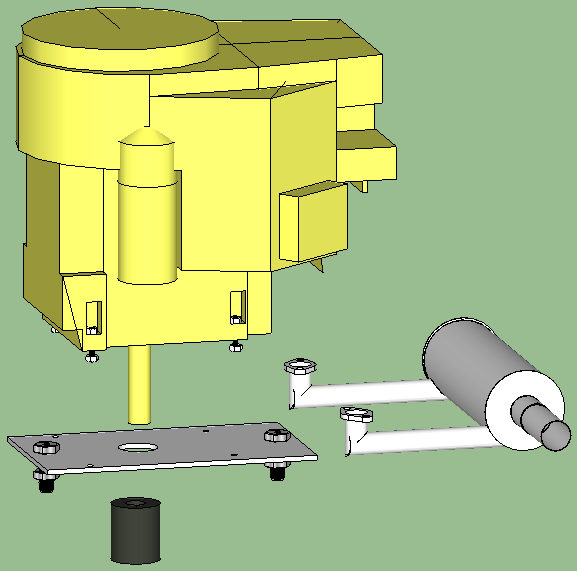

- Quick attach adaptor plate - allows for easy handling with tractors and skid loaders (possibly this would be unnecessary as quick attach points could be included in frame design)

Power cube module frames

Designing standardised features and sizes for power cube module frames would provide maximum modularity.

Joining power cubes

A system for joining power cubes would need to be designed. Main criteria for the design would be -

- Easy to join heavy power cubes by hand - using mechanical advantage cubes are pulled together. Guides ensure that cubes are easily correctly aligned.

- Quick and robust coupling of rotational drive. Possibly use a suitably rated PTO quick coupling [1]

Attachment points

Offering a number of standardised attachment points around the frame would allow mounting, around the power cube, of various components. The power cube frame could also be effectively used as the frame, or part of the frame, for machines - as shown in this MicroTrac concept [2]

Wheels

Could have either hydraulic, electric, mechanical or no drive. A system that allowed a pair of wheels to be position at various positions from front to back of the cube would allow it to be balanced when attached to other cubes or other attachments. In some applications it may be useful if the wheels can be attached to the cube while it sits on the ground with some mechanism allowing the wheels to then be lowered, lifting the cube from the ground.

Hydraulic control block

Electrical control panel

Handles

For manual manoeuvring of wheeled power cubes

Hybrid electric power

Using a battery bank, a motor an engine to provide a source of rotational power (steam or internal combustion engine), and a generator a hybrid electric power source could be created to provide rotational power. The engine could be removed from the machine when a task would require no more energy than is stored in the batteries. There are options to how this could be achieved.

Separate generator and motor

An electric motor provides the rotational power. This is powered by battery bank, with an engine, which is coupled to a generator providing electric power when the batteries are reduced in charge. The engine could be tuned to run extremely efficiently and electrical power produced, above that which is immediately required could be fed into the battery bank.

Combined motor/generator with straight through drive

An engine is coupled to a clutch unit and then a combined motor/generator. Rotational power can be provided by the engine, motor or engine and motor combined. When the engine is running, any unused rotational power can be converted to electrical power by the motor/generator and stored in the battery bank.

Mounting power cube modules to vehicles

The weight of some power cube modules or module combinations will negate the possibility for manual lifting. Some thought needs to go into how it would be possible to mount these to vehicles. This will require vehicle design to take into consideration these heavier power cubes. Possible options include -

- Design of wheels and handle attachments on cubes allow them to be lifted up into position - in combination with a vehicle design where the power cube mounting position takes into consideration such mounting.

- Vehicle has a cradle that lowers to allow cubes to be mounted before they are lifted up out of harms way

- Vehicle has a hydraulic (or electric?) system (which could possibly also offer vehicle suspension) that allows the vehicle frame (probably only one end required) to be lowered to facilitate power cube mounting/dismounting